Custom auto body modifications offer personalization but carry risks. Improper welds and misaligned panels can compromise structural integrity, while hazardous chemicals require proper ventilation and protective gear. Safety precautions like adequate ventilation, PPE, regular tool maintenance, optimal lighting, and fire safety are essential in workshops. Reliability is paramount, demanding meticulous craftsmanship, high-quality materials, and stringent standards to ensure long-term performance and structural integrity.

In the realm of custom auto body modification, creativity knows no bounds. However, navigating the intricate landscape of safety considerations is paramount to ensure both the integrity of the vehicle and the well-being of technicians. This article delves into the crucial aspects of understanding potential risks in custom auto body mods, implementing essential safety precautions within workshop environments, and guaranteeing the long-term reliability of modified vehicle components. By adhering to these guidelines, folks can revolutionize their rides securely.

- Understanding Potential Risks in Custom Auto Body Mods

- Essential Safety Precautions for Workshop Environments

- Ensuring Long-Term Reliability of Modified Vehicle Components

Understanding Potential Risks in Custom Auto Body Mods

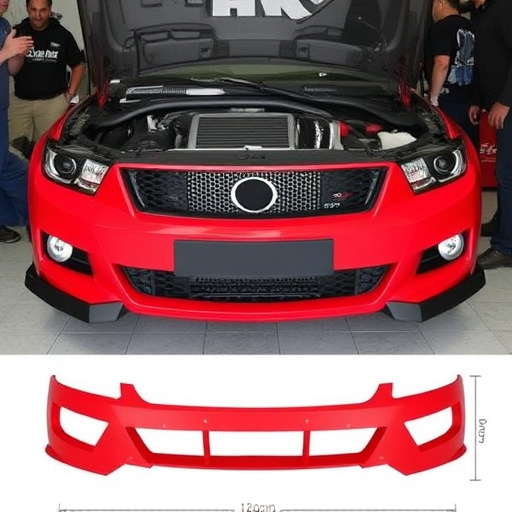

Custom auto body modification projects can be exciting endeavors for car enthusiasts looking to personalize their vehicles. However, it’s crucial to understand that this intricate work involves several potential risks. One of the primary concerns is ensuring structural integrity during modifications. Altering a vehicle’s body panel might impact its overall strength and stability, especially if not done correctly. Improper welds or misaligned panels can lead to weaknesses that may compromise safety in the event of a vehicle collision repair.

Additionally, custom auto body mods often require working with various materials and techniques, some of which may pose health risks. Exposure to certain chemicals, fumes, or dust from metalworking can be hazardous if not adequately controlled. Proper ventilation and personal protective equipment (PPE) are essential to mitigate these dangers, ensuring the safety of both the enthusiast and any professional auto collision center involved in the project.

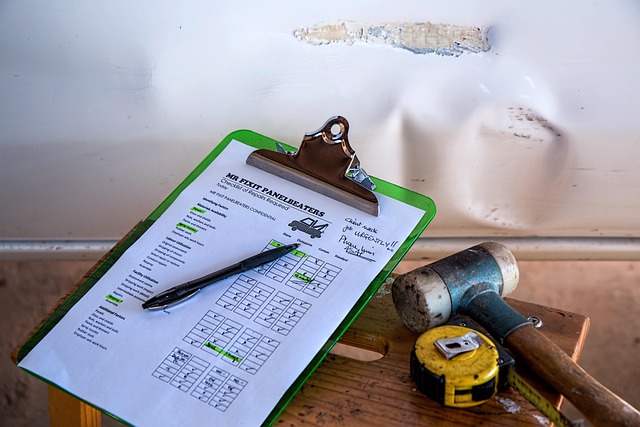

Essential Safety Precautions for Workshop Environments

In any workshop engaged in custom auto body modification, safety should never be compromised. Essential precautions include ensuring proper ventilation to mitigate the risks associated with fumes and dust from various materials used in the modifications. Personal protective equipment (PPE), such as gloves, safety glasses, and respirators, is non-negotiable for both technicians and visitors alike, protecting against potential hazards like sharp edges, hot surfaces, and toxic substances.

Regular maintenance of tools and equipment is crucial to prevent accidents. This includes keeping floors clear of debris and ensuring machinery is in good working order. Proper lighting should be implemented throughout the workshop to facilitate clear visibility during work, especially when dealing with intricate car body restoration or bumper repair tasks. Additionally, implementing fire safety measures, such as fire extinguishers readily available, is vital to prepare for any unforeseen emergencies during car repair services.

Ensuring Long-Term Reliability of Modified Vehicle Components

When it comes to custom auto body modification work, ensuring long-term reliability is paramount. Beyond the initial aesthetic appeal, modified components must withstand routine use and varying environmental conditions over an extended period. This requires meticulous craftsmanship and attention to detail throughout every step of the customization process. Using high-quality materials and adhering to stringent manufacturing standards for each replacement part or addition guarantees structural integrity, preventing premature failure or safety hazards down the line.

Properly executed custom auto body modifications integrate seamlessly with the vehicle’s existing systems, ensuring reliable performance and longevity. This encompasses not just structural components but also aesthetic enhancements that maintain their form and finish over time. For instance, dent repair techniques should aim to restore original smoothness without compromising the integrity of the body panel. Similarly, classic car restoration projects demand meticulous care in preserving historical accuracy while employing modern safety features where applicable, blending old-world craftsmanship with contemporary safety standards. Ultimately, prioritizing long-term reliability translates into peace of mind for vehicle owners, knowing their modified rides are as safe and dependable as ever on the road.

In conclusion, while custom auto body modification offers unique opportunities for vehicle customization, it’s crucial to prioritize safety. By understanding potential risks, implementing essential workshop precautions, and ensuring long-term reliability of components, modificators can create safe, high-quality results that enhance the driving experience without compromising integrity or legal compliance. These safety considerations are paramount in the dynamic world of custom auto body modification.