The integration of digital technology in auto maintenance has revolutionized the post-repair inspection process. Advanced imaging systems and cloud-based platforms ensure faster, more accurate inspections, accessible repair history, and real-time collaboration. This data-driven approach enhances consistency, reduces turnaround times, and ultimately boosts customer satisfaction by providing clear records and high-quality repairs, making it a significant post-repair inspection process game-changer for auto repair shops.

In today’s digital era, the post-repair inspection process has undergone a transformative revolution. Digital technology is streamlining inspections, ensuring higher accuracy, efficiency, and cost savings. This article delves into the multifaceted role of digital tools and platforms in enhancing post-repair inspections. From advanced imaging and data analytics to real-time feedback mechanisms and predictive maintenance insights, digital solutions are reshaping the landscape of quality assurance. By digitizing record-keeping, businesses can gain valuable insights, anticipate future repairs, and optimize resources.

- The Role of Digital Technology in Streamlining Post-Repair Inspections

- – Exploring efficient digital tools and platforms for inspection processes

- – Benefits of digitisation: Time and cost savings, improved accuracy

The Role of Digital Technology in Streamlining Post-Repair Inspections

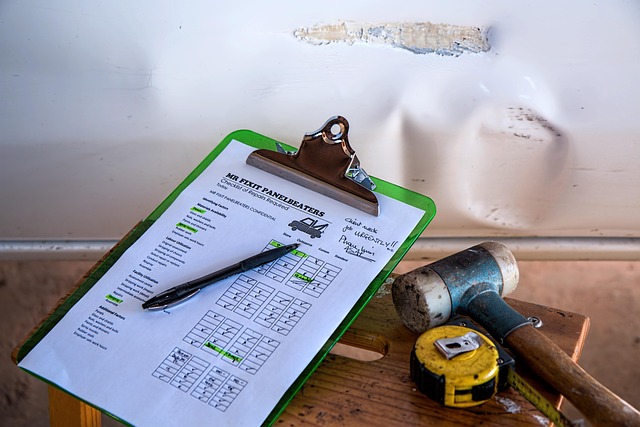

The integration of digital technology has revolutionized the post-repair inspection process, making it more efficient and accurate. Traditional methods often relied on manual checks and physical comparisons, which were time-consuming and prone to human error. Digital tools offer a streamlined alternative. For instance, advanced imaging systems capture detailed images of repaired vehicles, enabling inspectors to compare them with original specifications digitally. This ensures that every aspect of the repair, from auto body painting to intricate panel alignment, meets the required standards.

Moreover, digital platforms facilitate comprehensive documentation and record-keeping. Inspectors can now access a history of repairs, maintenance records, and manufacturer guidelines instantly. This data-driven approach enhances consistency and enables faster decision-making during post-repair inspections, especially in cases of car collision repair. As a result, businesses can reduce turnaround times and improve overall customer satisfaction with auto maintenance services.

– Exploring efficient digital tools and platforms for inspection processes

In today’s digital era, efficient post-repair inspection processes are more attainable than ever before. Digital technology offers a range of tools and platforms that streamline and enhance traditional inspection methods used in automotive repair, particularly in car body restoration and scratch repair services. One such game-changer is the implementation of specialized software designed to capture and analyze detailed images and data during the inspection phase. These digital solutions provide a comprehensive visual record, allowing professionals to identify even the slightest imperfections or discrepancies post-repair.

Moreover, cloud-based platforms facilitate seamless collaboration among team members, enabling real-time access to inspection reports and digital records. This ensures consistency and accuracy in quality control measures for various automotive repair tasks, from minor car scratch repairs to comprehensive car body restoration projects. By leveraging these efficient digital tools, businesses can optimize their post-repair inspection processes, ultimately leading to increased customer satisfaction and reduced turnaround times.

– Benefits of digitisation: Time and cost savings, improved accuracy

The digital transformation of the post-repair inspection process offers significant advantages for auto repair shops and their customers. One of the most notable benefits is the reduction in time and costs associated with traditional manual inspections. With digitized systems, auto dent repair and paintless dent repair processes become more efficient as digital tools enable faster and more precise assessments. This enhancement ensures that repairs are completed in a timely manner, reducing downtime for vehicle owners.

Moreover, digital technology improves accuracy in post-repair inspections. By utilizing specialized software and high-resolution imaging, technicians can capture detailed data, ensuring every aspect of the repair is documented and evaluated. This level of precision not only helps maintain quality standards but also facilitates better customer satisfaction as it provides a clear record of the restoration work performed on their vehicles, whether it’s an auto dent repair or more intricate paintwork.

Digital technology has revolutionized the post-repair inspection process, offering efficient digital tools and platforms that streamline operations. By embracing digitization, repair shops can achieve significant time and cost savings while enhancing accuracy. These advancements not only improve overall efficiency but also ensure a higher quality standard in vehicle maintenance, ultimately benefiting both businesses and customers alike.