Prioritize safety with protective gear for sectioning procedures in fleet repair. Implement critical measures like PPE, lit workspace, and personnel training. Conduct post-sectioning checks for accuracy, preventing structural issues and risks.

When performing sectioning procedures, adhering to robust safety protocols is non-negotiable. This comprehensive guide outlines essential safety gear, crucial precautions, and post-sectioning checks to ensure a secure working environment. From protective eyewear and gloves to proper waste disposal, understanding these protocols is vital for minimizing risks associated with sectioning. Implement these measures to maintain a safe workspace and prevent accidents during intricate sectioning processes.

- Understanding Essential Safety Gear for Sectioning

- Precautions Before and During the Process

- Post-Sectioning Checks: Ensuring Comprehensive Safety

Understanding Essential Safety Gear for Sectioning

Before embarking on any sectioning procedures, whether it’s for vehicle dent repair or complex collision center work, understanding and equipping yourself with the right safety gear is paramount. This includes protective eyewear, heavy-duty gloves designed to withstand impact, and a well-fitting respirator to guard against airborne debris and chemicals.

In the realm of fleet repair services, where precision meets potential hazards, each piece of safety gear serves a crucial purpose. Protective clothing that shields against cuts, abrasions, and heat is also essential. Remember, proper safety protocols not only ensure the integrity of your work but also safeguard you from unforeseen risks associated with sectioning procedures.

Precautions Before and During the Process

Before initiating any sectioning procedures, whether for automotive restoration or vehicle body repair at a collision repair center, several vital precautions must be taken to ensure safety. This includes donning appropriate personal protective equipment (PPE), such as safety glasses and gloves, to shield against debris and potential hazards. Additionally, ensuring the workspace is well-lit and clear of obstructions is crucial for a safe and efficient process. A thorough understanding of the tools and equipment to be used, including their proper handling and application, should be acquired by all personnel involved.

During the sectioning process itself, maintaining a calm and focused mindset is essential. Operators must adhere strictly to established protocols, keeping in mind that precision and patience are key. Regular breaks and clear communication among team members can help maintain alertness and avoid mistakes commonly associated with tedious tasks. Remember, safety in a collision repair center’s automotive restoration sectioning procedures is paramount for both employees and the vehicles under repair.

Post-Sectioning Checks: Ensuring Comprehensive Safety

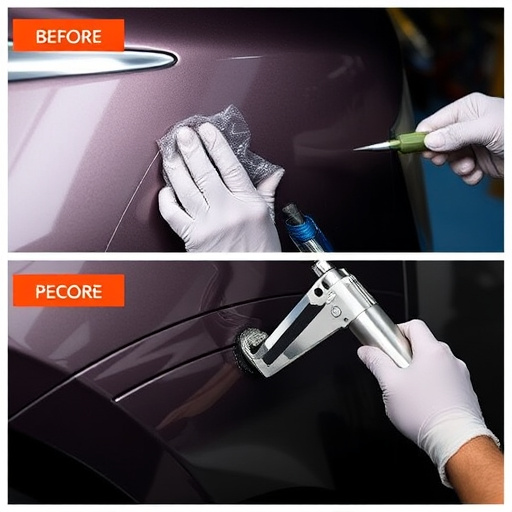

After completing sectioning procedures, conducting thorough post-sectioning checks is paramount to ensuring safety and quality in a collision repair center or automotive body work shop. These checks serve as critical validation steps, allowing technicians to verify that each panel has been accurately separated and positioned correctly during the intricate process of auto body repairs. By meticulously inspecting the joints, welds, and alignment, they can identify any discrepancies or potential hazards that may have gone unnoticed earlier.

Comprehensive post-sectioning checks encompass visual examinations, dimensional measurements, and functional tests to ensure seamless integration once the car repair services are finalized. This meticulous process not only safeguards against future structural failures but also ensures customer satisfaction by delivering a vehicle with reliable and durable automotive body work, free from any unforeseen safety risks.

When adhering to strict safety protocols during sectioning procedures, professionals can mitigate risks effectively. By understanding essential safety gear, taking necessary precautions, and performing post-sectioning checks, you ensure a comprehensive approach to safety in this critical process. Remember that implementing these measures is key to maintaining a safe work environment and upholding the highest standards of care.