Quality Control (QC) is vital for ensuring customer safety assurance in automotive industries, particularly during collision damage repair and car body restoration. Meticulous evaluation of each repair step prevents hazards and defects, maintaining vehicle integrity and occupant safety. Proper training and protocol adherence foster trust through reliable and secure automotive care. Integrating robust QC processes, standardized protocols, regular staff training, and digital tools enhances customer satisfaction and trust in collision repair services.

In the pursuit of fostering customer trust, quality control (QC) stands as a cornerstone of consumer safety assurance. This article delves into the intricate relationship between robust QC practices and their direct impact on safeguarding customers. We explore fundamental QC concepts, highlighting how they mitigate risks and ensure product excellence. Furthermore, we unveil strategic integrations to enhance customer confidence, showcasing the transformative power of QC in today’s competitive market. By understanding these connections, businesses can strengthen their commitment to customer safety assurance.

- Understanding Quality Control Fundamentals for Customer Safety

- Direct Impact of QC on Ensuring Consumer Well-being

- Strategies to Integrate QC and Strengthen Customer Assurance

Understanding Quality Control Fundamentals for Customer Safety

Quality Control (QC) is a fundamental process that directly impacts customer safety assurance in any industry, particularly in automotive services like collision damage repair and car body restoration. At its core, QC involves systematic procedures to ensure products or services meet predefined standards and specifications. In the context of customer safety, this means evaluating every step of the repair or restoration process to prevent any potential hazards or defects that could compromise vehicle integrity and occupant safety.

For example, in dent removal processes, QC measures ensure that dents are not only visually appealing but also structurally sound. Proper training and adherence to quality control protocols are vital to guarantee that repairs are executed accurately, utilizing the right techniques and materials. This direct link between quality control and customer safety assurance is what fosters trust among consumers, ensuring they receive reliable and secure services every time they engage with automotive care providers.

Direct Impact of QC on Ensuring Consumer Well-being

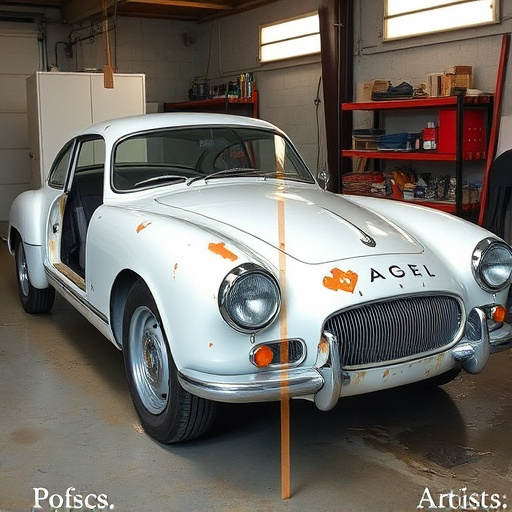

The direct impact of Quality Control (QC) on ensuring consumer well-being is profound and multifaceted. In industries like automotive repair, where precision is paramount, QC plays a pivotal role in maintaining customer safety assurance. For instance, consider Mercedes Benz collision repair—a meticulous process that relies heavily on effective QC measures to restore vehicles to their pre-accident condition. Skilled technicians, utilizing advanced tools and techniques such as paintless dent repair, must adhere to stringent quality standards to guarantee not just the aesthetic integrity but also the structural safety of the vehicle.

A robust QC system in a collision repair shop acts as a shield for consumers. It ensures that every step of the repair process meets or exceeds industry standards, minimizing risks associated with subpar workmanship. By implementing rigorous inspections and testing procedures, QC teams can identify and rectify defects early on, preventing potential hazards down the line. This is especially crucial when dealing with complex repairs, where even a minor oversight could have significant implications for customer safety. Thus, QC serves as a critical link between the workshop and the road, safeguarding consumers and promoting their trust in the services rendered by collision repair shops.

Strategies to Integrate QC and Strengthen Customer Assurance

Integrating Quality Control (QC) processes into vehicle collision repair and auto painting services is a strategic move to enhance customer safety assurance. To achieve this, workshops should adopt comprehensive QC strategies that encompass every stage of the repair process, from initial assessment to final inspection. One effective approach is to establish clear, standardized protocols for each type of service, ensuring consistent quality and safety across all repairs, be it car dent removal or more complex bodywork.

Regular staff training on these protocols and continuous improvement initiatives can further strengthen QC practices. By fostering a culture of meticulous attention to detail, workshops can minimize errors and defects, ultimately boosting customer satisfaction and trust. Incorporating digital tools for documentation and data analysis also streamlines the QC process, enabling efficient tracking of repairs, identifying trends, and making informed decisions to continually improve customer safety assurance in auto painting and vehicle collision repair services.

Quality control (QC) is not just a vital process in manufacturing; it serves as a cornerstone for fostering customer safety assurance. By understanding QC fundamentals, implementing effective strategies, and integrating them into business practices, companies can significantly enhance consumer well-being. This ensures that products meet high standards, reducing risks and increasing customer trust, ultimately strengthening market competitiveness.