In automotive maintenance, especially for electric and hybrid vehicles, adhering to strict repair quality inspections is crucial for safety and performance. These inspections encompass detailed examinations of high-voltage battery systems, electric motors, charging infrastructure, auto body repairs, and structural integrity. By following manufacturer guidelines, utilizing advanced diagnostics, and using high-quality parts, collision centers ensure reliable vehicle operation, optimal performance, and customer satisfaction through meticulous repair quality inspections at every stage.

In the ever-evolving automotive landscape, ensuring the highest standards of repair quality is paramount, especially for electric and hybrid vehicles. This comprehensive guide delves into the crucial aspects of repair quality inspection, a critical process that guarantees safety and performance. From understanding industry standards to identifying key components unique to electric/hybrid systems, we explore best practices to ensure accurate repairs, maintaining the integrity of these innovative vehicles.

- Understanding Repair Quality Inspection Standards

- Key Components in Electric/Hybrid Vehicle Inspections

- Best Practices for Ensuring Accurate Repairs

Understanding Repair Quality Inspection Standards

In the realm of automotive maintenance, especially for electric and hybrid vehicles, understanding repair quality inspection standards is paramount. These standards ensure that every vehicle undergoes rigorous scrutiny to maintain safety and performance levels. For luxury car brands like Mercedes-Benz, collision repair is a precise science, where every detail, from body panels to intricate electrical systems, must be meticulously restored to their pre-incident condition.

Automotive collision repair involves more than just fixing visible damages; it encompasses the alignment of structural components, the replacement of worn-out parts, and the recalibration of advanced safety systems. Repair quality inspection standards guide technicians through this process, ensuring that each step aligns with industry best practices. This meticulous approach guarantees not only the aesthetic restoration of vehicles but also their reliable performance on the road, giving owners peace of mind and enhancing customer satisfaction, be it for a Mercedes-Benz collision repair or any other automotive bodywork services.

Key Components in Electric/Hybrid Vehicle Inspections

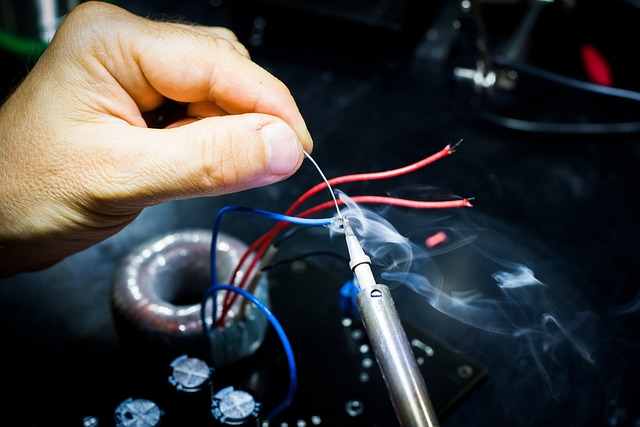

In a comprehensive repair quality inspection for electric and hybrid vehicles, several key components require meticulous attention. These include examining the vehicle’s high-voltage battery system, which is a critical element in ensuring safe operation and optimal performance. Technicians must check for any signs of damage, corrosion, or component failure that could compromise the integrity of the entire system. The electric motor and its associated power electronics are also vital areas, as they convert stored energy into motion, demanding rigorous testing to verify efficiency and functionality.

Additionally, inspections should encompass the vehicle’s charging infrastructure, considering both the on-board charger and external charging stations. Proper functioning of these components is essential for convenient and effective recharging, especially in hybrid models that require a balance between electric and conventional power sources. Just as important are auto body repairs and the overall structural integrity of the vehicle, ensuring that any damage, whether from accidents or normal wear and tear, is addressed to maintain safety standards. An auto collision center’s expertise in these areas plays a significant role in preparing electric and hybrid vehicles for safe return to the road after repairs.

Best Practices for Ensuring Accurate Repairs

Maintaining high standards during the repair process is paramount for ensuring customer satisfaction and vehicle safety. To achieve precise repairs, especially in the complex worlds of electric and hybrid vehicles, a systematic approach is essential. This includes following detailed procedures specific to each make and model, utilizing advanced diagnostic tools to accurately identify issues, and adhering to manufacturer guidelines strictly.

Best practices for collision repair and auto body repair professionals include using high-quality parts that meet or exceed original equipment specifications, regularly training staff on the latest techniques and technologies, and fostering an environment of continuous improvement. Regular repair quality inspections at every stage of the repair process—from initial assessment to final re-inspection—are crucial to catch any discrepancies early. This meticulous approach guarantees repairs are not just visually appealing but also function optimally, ensuring customer trust in their vehicle’s safety and reliability.

Repair quality inspection is paramount for ensuring electric and hybrid vehicles meet safety standards and perform optimally. By adhering to stringent inspection protocols, professionals can accurately assess repairs, safeguard vehicle functionality, and enhance consumer trust. Incorporating key components and best practices ensures every repair is of the highest caliber, fostering a reliable and sustainable transportation ecosystem.