MIG brazing collision repair is a specialized technique using Metal Inert Gas welding machines for precise and strong metal joining. Skilled technicians apply it in bumper, dent, and structural repairs, enhancing vehicle durability. For Mercedes-Benz repairs, MIG brazing effectively addresses cracks, corrosion, and panel replacement with minimal paint impact. Post-brazing preparation involves cleaning, sanding, priming, and painting for a professional finish that matches the vehicle's original appearance, demonstrating the expertise of the auto repair shop.

“MIG brazing has emerged as a pivotal process in the collision repair industry, offering precise and effective metal joining. This article delves into the intricacies of MIG brazing and its profound effects on paint preparation and refinishing. We explore the techniques and considerations for optimal paint preparation, ensuring long-lasting and professional results after this advanced welding method.

Understanding MIG brazing’s role in collision repair is crucial for achieving superior finishes, as it seamlessly fuses components, setting the stage for meticulous refinishing.”

- Understanding MIG Brazing: A Key Process in Collision Repair

- The Impact on Paint Preparation: Techniques and Considerations

- Refinishing After MIG Brazing: Achieving a Professional Finish

Understanding MIG Brazing: A Key Process in Collision Repair

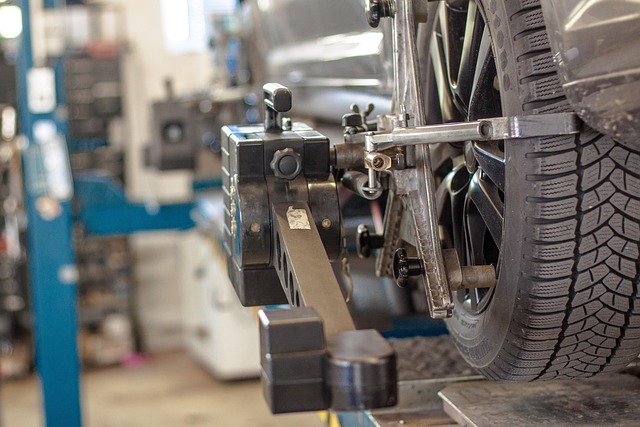

MIG brazing is a specialized technique that has become an indispensable process in the field of collision repair. It involves using a Metal Inert Gas (MIG) welding machine to fuse and join metal components with exceptional precision and strength. This method is particularly crucial when it comes to restoring vehicles, especially after accidents or damage. By employing MIG brazing, skilled technicians can effectively repair and refine various automotive parts, ensuring they meet the highest standards of quality and safety.

In the realm of bumper repair, car dent repair, and vehicle collision repair, MIG brazing offers a reliable solution for restoring structural integrity. It allows for the precise manipulation of metal, enabling the seamless fusion of panels, frames, and other critical components. This highly effective process ensures that damaged vehicles are not only visually restored but also left with enhanced durability, making them safer on the road.

The Impact on Paint Preparation: Techniques and Considerations

MIG brazing has a profound impact on paint preparation in collision repair, offering both advantages and unique considerations for vehicle body shops. This efficient technique involves using a metal inert gas to create a strong bond between components, which is particularly beneficial for intricate Mercedes-Benz repairs or any car damage scenarios. By precisely melting and fusing metal surfaces, MIG brazing can seamlessly mend cracks, corrosion, and even replace missing panels with minimal disruption to the surrounding paintwork.

When preparing a vehicle for refinishing after MIG brazing, careful techniques are essential. This includes thoroughly cleaning the area to remove any debris or remaining brazing material. Sanding is often required to create a smooth surface, ensuring that the new paint adheres properly. Professional body shops understand the importance of proper surface preparation, using specialized tools and expertise to achieve a flawless finish when it comes to mercedes benz repair or any high-quality vehicle restoration.

Refinishing After MIG Brazing: Achieving a Professional Finish

After completing MIG brazing during collision repair or automotive restoration, achieving a professional finish requires careful consideration and precise techniques. The process involves several critical steps to ensure the final coat looks as good as new. First, properly prepare the surface by thoroughly cleaning and degreasing it to remove any contaminants that could affect paint adhesion. This meticulous attention to detail is crucial for the success of the refinishing project.

Next, apply an appropriate primer to create a smooth base and seal the metal. A high-quality primer ensures better paint coverage and longevity. Then, choose a suitable paint system designed for automotive applications, typically a base coat followed by a clear coat for added protection and a glossy finish. Proper application techniques, including even spraying and minimal overspray, are essential to achieving a professional look. This meticulous process transforms the repaired area into a seamless continuation of the vehicle’s original finish, showcasing the skills of an expert auto repair shop.

MIG brazing has emerged as a game-changer in the collision repair industry, offering precise and efficient paint preparation. This process significantly enhances the overall refinishing outcome, ensuring a professional and durable finish. By understanding the unique techniques and considerations involved, bodyshops can leverage MIG brazing to deliver high-quality repairs that meet customer expectations.