Blending panels is a critical process in automotive repair, ensuring seamless finishes by merging colors and concealing previous damage. Technicians prepare surfaces through cleaning, sanding, and using tools for gap filling, smoothing, and sealing. This meticulous approach avoids visible collisions of paint types, textures, and colors, achieving high-quality, professional results that match the vehicle's original design.

Before achieving a seamless blend in paint, shops meticulously prepare adjacent panels. This process, crucial for minimizing visible transitions between panels, involves understanding the blending impact and surface preparation. By navigating the collision of colors, these steps ensure a professional finish. From cleaning and deburring to priming and sanding, each step plays a vital role. Techniques like wet blending and using masking tape refine the final touch, making adjacent panels appear as one cohesive unit.

- Understanding the Blending Process and its Impact on Adjacent Panels

- Preparing the Surface: Key Steps to Ensure a Smooth Blend

- Techniques for Achieving a Seamless Collision of Panels

Understanding the Blending Process and its Impact on Adjacent Panels

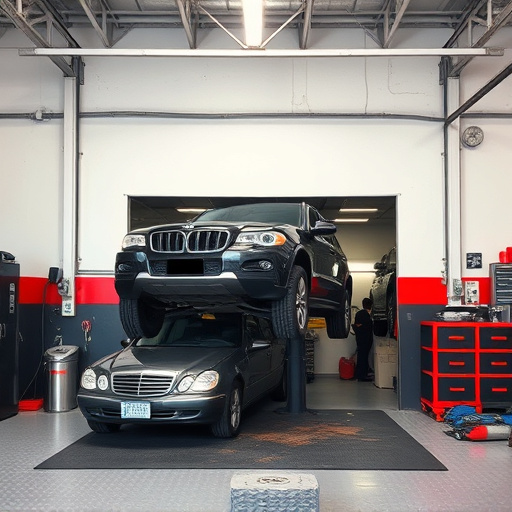

The blending process is a critical step in achieving a seamless finish when painting adjacent panels on vehicles. It involves carefully merging distinct colors or tones to create a smooth transition, ensuring no visible lines or inconsistencies are left behind. This technique is particularly crucial for automotive repair services and body shop services where precision is key to preserving the vehicle’s aesthetics. When preparing for blending, shops must consider the potential collision of different paint types, textures, and colors, especially if the panels have been previously painted or repaired.

Understanding how these elements interact is essential to avoid visible gaps or ripples in the final finish. Skilled technicians employ various tools and techniques, such as wet sanding and specialized blending brushes, to create a gradual blend that mimics the natural contours of the vehicle’s surface. This meticulous process guarantees that each panel seamlessly integrates with its neighbor, resulting in a professional, high-quality paint job that masks any previous damage or repairs, making the vehicle look as good as new.

Preparing the Surface: Key Steps to Ensure a Smooth Blend

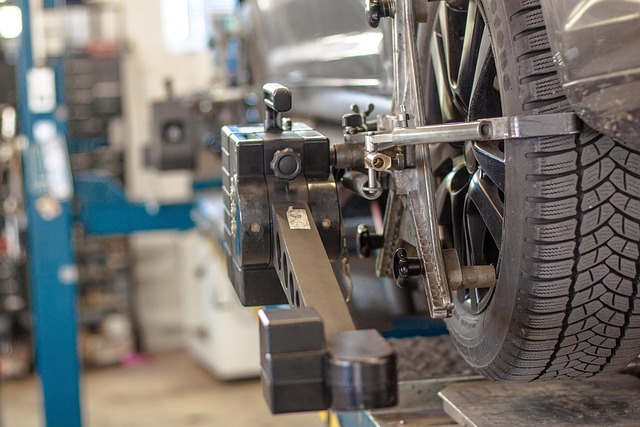

Preparing the surface is a crucial step in ensuring a seamless blend when working with adjacent panels on vehicles. It involves meticulous attention to detail and the use of specific techniques to create an even base for paint application. The process begins by thoroughly cleaning the panels, removing any dirt, grease, or existing debris that could hinder adhesion. This often includes using specialized cleaners and decontaminants, especially in the case of tire services, where rubber residue can be a significant concern.

Once cleaned, the surface must be prepared to accommodate the paint’s proper adherence. For vehicle bodywork, this may involve sanding to create a rough texture that allows the paint to bond more effectively. It is essential to use the right grit of sandpaper and apply even pressure across the panels’ edges where they meet. This step is particularly vital when blending panels to avoid visible collisions or gaps in the final finish, ensuring a professional-looking auto maintenance job.

Techniques for Achieving a Seamless Collision of Panels

Achieving a seamless collision of adjacent panels is paramount to ensuring the aesthetics and integrity of any vehicle’s exterior. Before blending paint, shops employ various techniques to prepare these panels for a perfect fusion. One common method involves using specialized tools to smooth out any gaps or irregularities between the panels. This can include handheld scrapers and sanders designed to create a clean, even surface, eliminating any traces of debris or previous repair work.

Additionally, professional technicians may employ putty or sealant to fill in minor gaps and imperfections. This step is crucial for auto glass repair, as it ensures that the panel collision won’t compromise structural integrity. Frame straightening techniques also play a vital role, especially after dent removal processes. By carefully aligning the panels, shops can guarantee that the final blend will be indistinguishable from the surrounding areas, creating a seamless appearance that matches the vehicle’s original design.

When preparing adjacent panels for blending paint, meticulous attention to detail is crucial. By understanding the blending process and its impact on adjacent panels, along with employing effective surface preparation techniques, professionals can achieve seamless collisions that enhance overall aesthetics. Mastering these methods ensures a smooth transition between panels, resulting in a visually appealing and durable finish.