High-strength steel (HSS) is a revolutionary material in automotive engineering, enhancing vehicle safety and durability. Its advanced properties enable lightweight, compact designs, improving fuel efficiency. HSS repairs are crucial for body shop services, ensuring structural stability during repainting or panel replacement. This method preserves the vehicle's original aesthetics and extends its lifespan, reducing costs. The repair process involves precise assessment, welding, drilling, and frame straightening using modern tools in dedicated collision centers, guaranteeing superior bodywork standards.

In today’s automotive landscape, high-strength steel (HSS) plays a pivotal role in enhancing vehicle safety and durability. This advanced material is integral to modern car designs, offering superior strength-to-weight ratios and improved crash performance. The importance of HSS repair cannot be overstated; it ensures structural integrity, preserves vehicle value, and guarantees passenger safety. This article explores the benefits and processes behind high-strength steel repair, shedding light on why it’s an indispensable practice in automotive maintenance.

- Understanding High-Strength Steel and its Role in Automotive Repair

- Benefits of High-Strength Steel Repair for Vehicle Safety and Durability

- The Process and Techniques Employed in High-Strength Steel Repair for Vehicles

Understanding High-Strength Steel and its Role in Automotive Repair

High-strength steel (HSS) is a pivotal material in modern automotive engineering, renowned for its exceptional strength-to-weight ratio and durability. In the realm of vehicle repair, particularly for car restoration and body shop services, HSS plays a transformative role. This advanced steel grade offers unparalleled resistance to impact and corrosion, ensuring structural integrity and safety. When a vehicle sustains damage, whether from an accident or normal wear and tear, high-strength steel repairs provide a robust solution.

Compared to traditional steel types, HSS allows for more compact and lightweight designs in cars, enhancing fuel efficiency and performance. In car paint repair processes, the use of HSS is crucial as it maintains the vehicle’s structural stability during repainting or panel replacement. This ensures that the finished product not only looks pristine but also retains its structural soundness, making high-strength steel repair an indispensable aspect of quality body shop services.

Benefits of High-Strength Steel Repair for Vehicle Safety and Durability

High-Strength Steel Repair offers numerous advantages for enhancing vehicle safety and durability. This advanced technique utilizes specialized steels with superior mechanical properties, allowing for stronger and more resilient components. By replacing damaged or weakened parts with high-strength steel, vehicles can maintain their structural integrity, ensuring better performance in the event of an accident. This repair method is particularly beneficial for critical structures like frames, chassis, and body panels, where even minor imperfections can compromise overall safety.

Moreover, opting for high-strength steel repair can significantly extend a vehicle’s lifespan, delaying the need for more extensive (and costlier) repairs or replacements. Unlike traditional metal welding or patching, this process preserves the original vehicle design and structural precision. It also eliminates the need for unsightly scars from conventional repairs, preserving the car’s aesthetic appeal. Effective high-strength steel repair can be seamlessly integrated into auto painting services to ensure a flawless finish, both in terms of appearance and structural soundness, without requiring extensive car paint repair or complete auto painting overhauls.

The Process and Techniques Employed in High-Strength Steel Repair for Vehicles

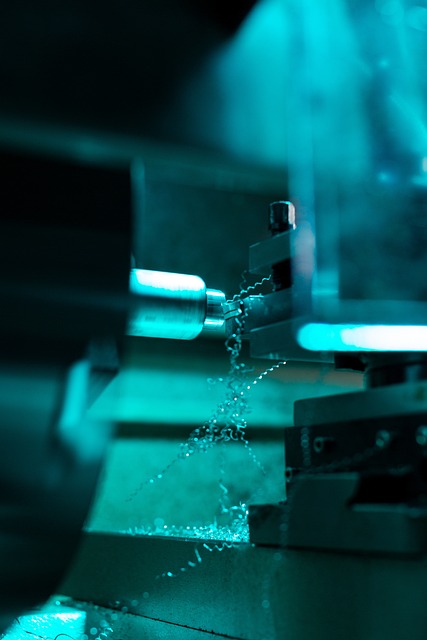

The process of high-strength steel repair for vehicles involves a meticulous series of steps designed to restore structural integrity without compromising safety. It begins with an assessment of the damage, which often requires specialized equipment and expertise to accurately identify hidden flaws within the metal. Technicians then employ various techniques such as welding, drilling, and specialized coatings to repair or replace damaged sections. Advanced methods like robotic welding ensure precision and consistency, minimizing the risk of new weaknesses developing.

These repairs go beyond mere aesthetics, focusing on reinforcing the vehicle’s frame and ensuring its structural soundness. Frame straightening is a critical component, aiming to realign any warped or bent metal to its original specifications. The use of high-strength steel in these repairs offers enhanced durability and crashworthiness, making the vehicle safer and more reliable. This meticulous approach is often carried out in dedicated collision centers equipped with state-of-the-art tools for accurate measurements and precise results, ensuring that each repair meets the highest standards of auto bodywork excellence.

High-strength steel repair is not just a trend; it’s a game-changer in the automotive industry. By understanding and leveraging the unique properties of high-strength steel, professionals can significantly enhance vehicle safety and durability. The advanced repair techniques employed ensure that vehicles return to their peak performance, offering peace of mind for drivers on the road. Embracing this technology is crucial for keeping up with modern transportation demands and ensuring a safer, more reliable automotive landscape.