Spot welding systems have revolutionized collision repairs by offering precise, efficient methods for joining metal sheets with robust bonds. These tools streamline operations in complex auto body shops, maintaining vehicles' aesthetic appeal and reliability. As a result, spot welding is the preferred choice for professionals due to its precision, time-saving benefits, and ability to enhance productivity while reducing labor costs. Selecting the right system, aligning with shop workflow and budget, ensures efficient processes, reduced downtime, and superior car damage repair results.

Spot welding systems have transformed collision repairs, offering precision and efficiency in auto body restoration. This article delves into the world of spot welding, providing a comprehensive guide for collision repair shops. We explore its advantages, from faster repairs to enhanced structural integrity. Additionally, we’ll help you choose the right spot welding system, highlighting key features to ensure top-quality, time-efficient repairs. Understanding these benefits and selection criteria is crucial for any modern auto body shop.

- Understanding Spot Welding Systems: A Primer for Collision Repairs

- Advantages of Using Spot Welding in Auto Body Repair and Restoration

- Choosing the Right Spot Welding System for Your Collision Repair Shop

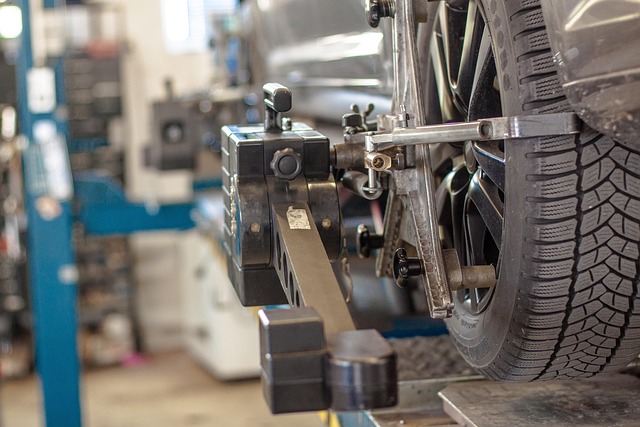

Understanding Spot Welding Systems: A Primer for Collision Repairs

Spot welding systems have become an indispensable tool in the realm of collision repairs, revolutionizing how auto body services are delivered. These advanced systems utilize concentrated heat to fuse two or more metal sheets together, creating robust bonds that can withstand rigorous testing. Unlike traditional joining methods, spot welding offers precise control over heat input, allowing for accurate and repeatable results. This precision is particularly beneficial in complex auto collision centers where multiple panels need to be joined seamlessly.

Understanding the fundamentals of spot welding systems is crucial for any professional in the auto body services industry. By focusing on specific points of contact, these systems minimize heat impact on surrounding areas, reducing the risk of unintended damage during the dent removal process. This not only enhances overall repair efficiency but also contributes to maintaining the vehicle’s original aesthetic appeal. Moreover, spot welding ensures structural integrity, making repaired vehicles safer and more reliable on the road.

Advantages of Using Spot Welding in Auto Body Repair and Restoration

Spot welding systems offer several advantages in auto body repair and restoration processes, making them a preferred choice among professional body shops. One of the key benefits is their precision and efficiency. These systems allow for accurate and quick welds, which is crucial when dealing with complex vehicle structures. With spot welding, technicians can precisely join metal panels, ensuring structural integrity without compromising aesthetics. This precision is particularly valuable in repairing damaged cars, as it enables the restoration of original factory finishes, maintaining the car’s overall value.

Additionally, spot welding systems enhance productivity and reduce labor costs for body shop services. The process is faster than traditional methods, allowing shops to accommodate a higher volume of repairs, especially for auto dent repair tasks. By minimizing weld preparation and offering consistent results, these systems streamline the work, making car repair services more effective and cost-efficient. This efficiency translates into better customer satisfaction and a competitive edge for body shop businesses.

Choosing the Right Spot Welding System for Your Collision Repair Shop

Selecting the ideal spot welding system is a strategic decision for any collision repair shop, as it directly impacts efficiency and quality. When considering options, keep in mind that different systems cater to various needs. For instance, some are designed for heavy-duty applications, capable of handling complex car damage repairs, while others offer precision for more intricate auto painting tasks.

The right system should align with your shop’s workflow and budget. Look for features like adjustable settings, user-friendly controls, and compact designs that fit seamlessly into your collision center’s layout. Additionally, consider the material compatibility and weld quality to ensure it meets industry standards. With the right spot welding system in place, your repair shop can streamline processes, reduce downtime, and deliver superior results in car damage repairs.

Spot welding systems offer a multitude of benefits for collision repairs, from increased efficiency and precision to reduced material waste and labor costs. By investing in the right spot welding system, collision repair shops can enhance their productivity, improve quality, and ultimately provide better service to their customers. Choosing the appropriate system tailored to your shop’s needs is key to unlocking these advantages fully, ensuring a smoother, more successful repair process.