Computerized paint matching technology has revolutionized vehicle repair and restoration by ensuring perfect color accuracy using advanced algorithms and sensors that analyze bodywork hues, saturation, and value. This system streamlines work, reduces human error, and provides consistent, durable finishes in dent removal and repainting processes. Beyond automotive, this technology offers precise color matching for manufacturing sectors, enhancing product quality and branding through consistent color reproduction across large-scale production runs.

Discover how computerized paint matching revolutionizes color accuracy in today’s digital era. This advanced technology ensures perfect shades every time, transcending the limitations of manual mixing. From automotive painting to interior design, computerized paint matching offers unparalleled precision and efficiency. Learn about its intricate process, explore its diverse applications across industries, and understand why it’s become an indispensable tool for professionals seeking flawless results.

- Understanding Computerized Paint Matching Technology

- The Process of Achieving Color Accuracy

- Benefits and Applications in Various Industries

Understanding Computerized Paint Matching Technology

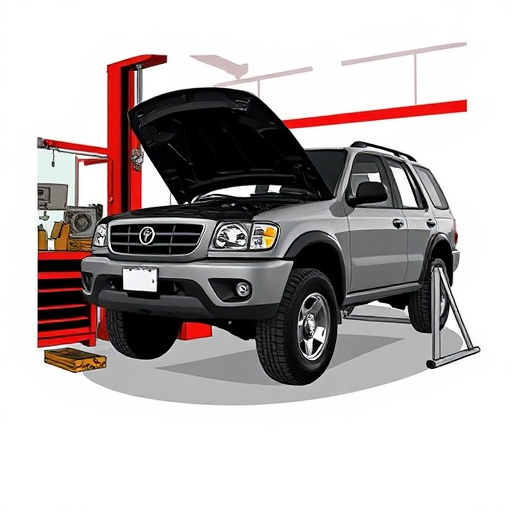

Computerized paint matching technology has revolutionized the way we ensure perfect color accuracy in vehicle repair services. This innovative system uses advanced algorithms and sensors to analyze and match the exact shade of paint on a vehicle’s bodywork, even after dent removal. By capturing detailed data about the existing paint, including its hue, saturation, and value, these systems can reproduce the original color with remarkable precision.

This technology is particularly beneficial for vehicle bodywork shops as it streamlines the process of repainting and refinishing. No longer do technicians have to rely on their manual skills and subjective judgments; instead, they can input the vehicle’s paint code or use an integrated database to access precise color information. This not only reduces the risk of human error but also ensures a more consistent and durable finish, enhancing the overall quality of dent removal services.

The Process of Achieving Color Accuracy

The process of achieving perfect color accuracy in computerized paint matching involves a meticulous series of steps designed to ensure that the new paint perfectly replicates the original finish. It begins with advanced scanning technology, which captures detailed images and data of the existing surface, down to the most subtle variations in shade and texture. This digital blueprint is then fed into sophisticated software algorithms that analyze the data, identifying specific color codes and nuances.

This information is used to source matching paint from manufacturers, ensuring not just visual similarity but also chemical compatibility with the original coat. In cases of complex repairs or restoration projects, like those involving paintless dent repair or automotive restoration, this process becomes even more critical. The computerized system must account for factors such as age, wear, and environmental exposure to deliver a final product that seamlessly integrates into the vehicle’s existing finish, maintaining its aesthetic appeal and structural integrity.

Benefits and Applications in Various Industries

Computerized paint matching technology has revolutionized various industries by offering unparalleled color accuracy and precision. This innovative system utilizes advanced algorithms and sensors to analyze and match colors with incredible detail, ensuring that every shade is perfectly replicated. One of its key benefits is the elimination of subjective human interpretation, which reduces the potential for errors in color mixing and application.

The applications of computerized paint matching are vast. In automotive repair and car restoration, it plays a crucial role in maintaining the original aesthetics of vehicles. By accurately matching the paint on damaged cars, restorers can achieve seamless blends that are indistinguishable from the original finish. This level of detail ensures customer satisfaction and preserves the historical integrity of vintage vehicles. Beyond automotive, this technology is also valuable in manufacturing, where consistent color matching is essential for product quality and branding. It enables companies to maintain high standards across large-scale production runs, ensuring every item leaves the factory with an identical appearance.

Computerized paint matching technology has revolutionized color accuracy across various industries. By understanding complex algorithms and precise measurement techniques, this innovative system ensures consistent, flawless results. From automotive manufacturing to interior design, computerized paint matching offers unparalleled benefits, streamlining processes, reducing waste, and enhancing aesthetic appeal. Its ability to deliver perfect matches makes it an indispensable tool for professionals seeking exceptional quality and consistency in their projects.