A safe repair environment is a key strategy for automotive body shops and collision centers to reduce workers' compensation claims, enhance productivity, and improve employee morale. By fostering a culture of safety through comprehensive training, providing PPE, implementing clear protocols for hazardous tasks like frame straightening, conducting regular inspections, maintaining tools, promoting open communication, and efficient workflow management, these facilities significantly lower accident risks, meet regulatory standards, and create a positive work environment that benefits both workers and business success.

A safe repair environment isn’t just about compliance; it’s a strategic investment in your business’s success. By prioritizing worker safety, you can significantly reduce workers’ compensation claims, lower insurance costs, and boost morale. This article explores the profound impact of a robust safety culture in repair operations, offers practical strategies for fostering a safe environment, and makes a compelling case for why making safety a top priority is good for both your bottom line and your workforce.

- Understanding the Impact of a Safe Repair Environment

- Strategies to Foster Safety in Repair Operations

- Lowering Workers' Compensation Claims: A Case for Safer Workspaces

Understanding the Impact of a Safe Repair Environment

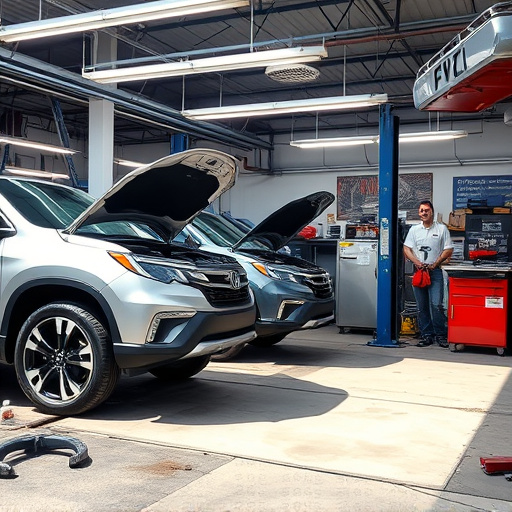

A safe repair environment is a fundamental cornerstone in reducing workers’ compensation claims within automotive workshops, particularly those offering body shop services and collision repair. By prioritizing safety, these facilities can significantly mitigate risks associated with tasks such as frame straightening and other intricate repairs. A culture of safety ensures that employees are well-trained, equipped with personal protective equipment (PPE), and familiar with proper handling procedures for hazardous materials or machinery.

This proactive approach not only protects workers from potential injuries but also fosters a responsible and efficient working atmosphere. When employees understand and adhere to safety protocols, it reduces the likelihood of accidents, thereby lowering the number of compensation claims. Moreover, a safe repair environment enhances overall productivity as staff can focus on tasks without constant concern for personal well-being, enabling them to deliver high-quality body shop services and collision repair with enhanced precision and speed.

Strategies to Foster Safety in Repair Operations

Creating a safe repair environment is paramount to reducing workers’ compensation claims and fostering a culture of safety in collision repair services. This begins with comprehensive training programs that educate employees on hazard identification, risk mitigation, and proper use of personal protective equipment (PPE). Implementing clear safety protocols for various tasks, such as car body restoration or classic car restoration, ensures every worker understands their role in preventing accidents.

Regular inspections and maintenance of tools, machinery, and facilities are essential elements of a safe repair environment. Keeping work areas organized, well-lit, and free from potential hazards significantly reduces the risk of injuries. Additionally, encouraging open communication where workers can report safety concerns or near-miss incidents without fear of reprisal plays a crucial role in continuous improvement. Incorporating these strategies not only lowers compensation claims but also enhances employee morale and overall job satisfaction within collision repair services.

Lowering Workers' Compensation Claims: A Case for Safer Workspaces

In today’s competitive business landscape, reducing workers’ compensation claims is a critical strategy for any automotive body shop or car collision repair center. A safe repair environment isn’t just about adhering to regulations; it’s a proactive approach that fosters a culture of safety and well-being among employees. By prioritizing the health and security of their workforce, businesses can significantly lower the risk of accidents and injuries, thereby decreasing workers’ comp claims.

Implementing robust safety protocols, such as proper training, personal protective equipment (PPE), and efficient workflow management, creates a more predictable and controlled environment. For instance, a well-organized paintless dent repair area reduces the chances of slips, falls, or collisions that often lead to compensation claims. Such measures not only protect workers but also enhance operational efficiency, ensuring that automotive body shops can maintain high productivity levels while keeping costs associated with worker injuries to a minimum.

A safe repair environment is not just a moral obligation; it’s a strategic imperative that significantly reduces workers’ compensation claims. By implementing robust safety protocols and fostering a culture of mindfulness, repair operations can create a more secure workspace. This, in turn, leads to happier employees, lower insurance costs, and improved operational efficiency. Embracing these strategies is a win-win for both employees and employers, ultimately contributing to a healthier, more productive work environment.