Undercarriage inspection repair is a vital yet often missed step in vehicle maintenance, focusing on critical components beneath the car's body. Regular checks prevent severe damage, enhance performance, improve fuel efficiency, and extend vehicle lifespan. Advanced diagnostic tools streamline this process, allowing for efficient identification and repair of issues like leaks and worn-out parts. A well-prepared, coordinated, and updated inspection ensures high-quality repairs, faster turnaround times, and cost savings for clients.

In the realm of automotive maintenance, a thorough undercarriage inspection repair is paramount for both safety and vehicle longevity. This article delves into the efficient combination of diagnostics and undercarriage repair, emphasizing its growing importance in today’s digital era. We explore the significance of regular undercarriage inspections, discuss integrating advanced diagnostic tools for precise repairs, and offer best practices to streamline the process, ensuring optimal vehicle performance and minimal downtime. Mastering these techniques is a game-changer for fostering vehicle health and safety on the road.

- Understanding the Importance of Undercarriage Inspection

- Integrating Diagnostic Tools for Efficient Repairs

- Best Practices for Seamless Undercarriage Repair Process

Understanding the Importance of Undercarriage Inspection

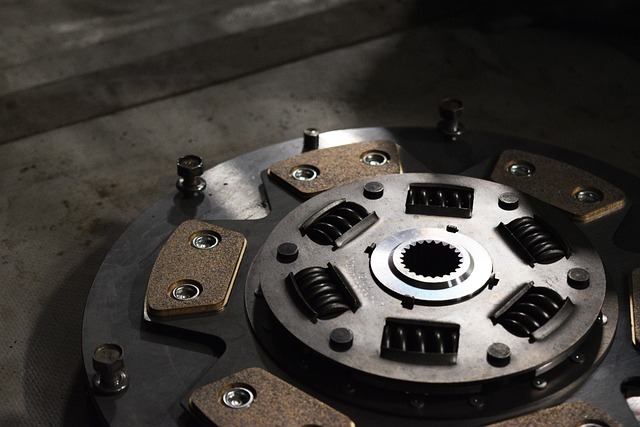

Undercarriage inspection is a critical yet often overlooked aspect of vehicle maintenance. It involves a thorough examination of the components beneath the vehicle’s body, which are vital for both safety and performance. By combining diagnostics with undercarriage inspection repair, auto shops can offer comprehensive services that not only identify potential issues but also resolve them effectively. This two-pronged approach ensures that every nook and cranny of your vehicle is checked, from the exhaust system to the suspension parts and everything in between.

Regular undercarriage inspections are essential for catching problems early on, preventing more severe damage, and ensuring smooth driving. It’s not just about aesthetics; a well-maintained undercarriage can significantly impact fuel efficiency and overall vehicle longevity. Whether it’s a modern car needing auto glass repair or a classic car undergoing a restoration, undercarriage inspection repairs play a pivotal role in keeping your vehicle in top shape. This proactive maintenance is key to avoiding costly repairs down the line and ensuring safety on every journey.

Integrating Diagnostic Tools for Efficient Repairs

In today’s digital era, integrating advanced diagnostic tools has revolutionized undercarriage inspection and repair processes. These innovative solutions enable vehicle service centers to efficiently detect even the subtlest issues beneath a vehicle’s surface. By utilizing sophisticated sensors and software, technicians can swiftly identify damaged components within the undercarriage, ranging from leaks in the coolant system to worn-out suspension parts. This proactive approach ensures that repairs are not only timely but also precise, minimizing the scope for errors often associated with manual inspections.

Furthermore, integrating diagnostic tools streamlines the overall vehicle repair services, making them more accessible and cost-effective. Automotive repair professionals can quickly cross-reference symptoms with existing data libraries, facilitating faster diagnoses. This efficiency is particularly beneficial during complex undercarriage repair processes, where identifying the root cause of problems is crucial. As a result, clients benefit from reduced turnaround times and improved overall vehicle collision repair quality.

Best Practices for Seamless Undercarriage Repair Process

When it comes to best practices for a seamless undercarriage inspection repair process, preparation is key. Before beginning any work, thoroughly inspect the entire undercarriage, identifying any damage, corrosion, or potential issues. This meticulous approach ensures that every element is considered and addressed. Utilize advanced diagnostic tools to detect even the subtlest anomalies, as early identification can prevent more extensive repairs later. A well-prepared plan not only streamlines the repair process but also enhances overall efficiency.

Effective communication and coordination among the diagnostics team and repair technicians are vital. Clear communication ensures that everyone is on the same page regarding the extent of the damage and the proposed solutions. This seamless collaboration minimizes errors and delays, leading to faster turnaround times. Regular updates and progress checks keep all parties informed, fostering a smooth and successful undercarriage inspection repair process.

Undercarriage inspection and repair are vital components of vehicle maintenance, ensuring safety and performance. By integrating diagnostic tools and adopting best practices, technicians can efficiently address undercarriage issues, minimizing downtime and enhancing customer satisfaction. Regular undercarriage inspections, combined with advanced diagnostics, allow for proactive repairs, ultimately contributing to the longevity of vehicles and cost-effectiveness for both owners and repair shops. This efficient approach to undercarriage inspection repair is a game-changer in the automotive industry.