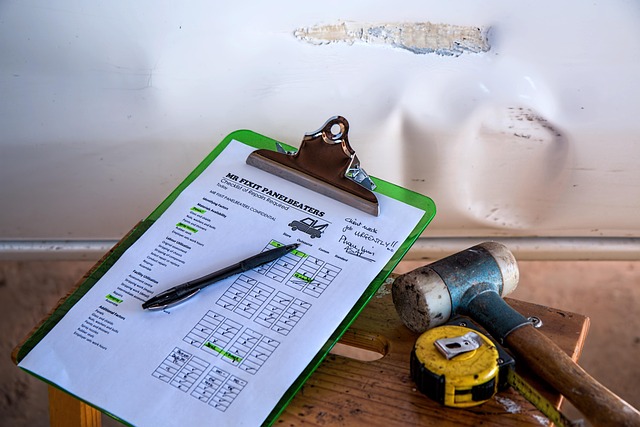

Resistance spot welding, a key technique in automotive repair, uses electric current and pressure to melt steel and aluminum, creating strong welds for car collision and dent repairs. This precise method minimizes heat input, preserving surrounding material and reducing vehicle distortions. By controlling parameters like current, voltage, pulse duration, and electrode gap, welders achieve consistent, high-quality welds, restoring structural integrity after incidents like fender benders to match manufacturer standards.

Unleash the power of resistance spot welding with our advanced tips and techniques. This precise, high-efficiency process is a cornerstone in modern manufacturing, offering exceptional strength and quality. From understanding the fundamentals—including key components and their roles—to mastering advanced techniques for optimal welds, this guide covers it all. Learn to navigate common challenges like HAZ distortion and cold shuts, ensuring consistent, repeatable results. Elevate your resistance spot welding skills today.

- Understanding the Basics of Resistance Spot Welding

- – Definition and process overview

- – Key components and their functions

Understanding the Basics of Resistance Spot Welding

Resistance spot welding is a precise and efficient technique used in various industries, particularly for automotive manufacturing and repair, including car damage repair and bumper repair services offered by many body shop services. It involves using an electric current to melt a small area of metal, creating a strong bond between two components. This process is highly versatile, suitable for joining metals like steel, aluminum, and their alloys, which are commonly used in modern vehicles.

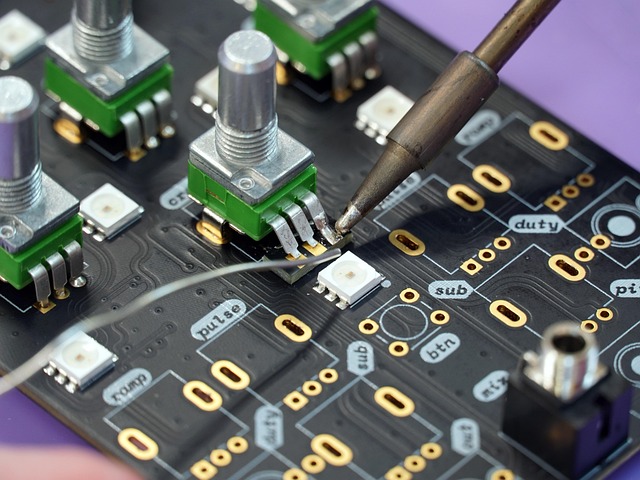

The basic principle revolves around the application of pressure and heat. An electrode, typically made of copper or a copper alloy, is brought into contact with the metal surfaces to be welded. A precise amount of pressure is applied while an electric current passes through the electrode and into the metal. This generates heat, melting the metal at the point of contact, and upon removal of the electrode, a solid weld is formed. Understanding this fundamental process is key to mastering advanced resistance spot welding techniques for high-quality body shop services and efficient car damage repair.

– Definition and process overview

Resistance spot welding is a specialized metal-joining technique that uses heat generated by electrical resistance to fuse two or more metal components together. This advanced process involves applying a concentrated electric current through a pair of electrodes, which generates intense heat in the contact zone between the metals. As a result, the metal melts and flows, creating a strong weld. The entire process is fast, efficient, and highly controlled, making it ideal for various applications, including car collision repair and vehicle dent repair in car bodywork services.

The technique’s precision allows for minimal heat input, preserving the surrounding material and reducing distortions. This makes resistance spot welding particularly versatile for intricate designs and tight spaces. By controlling parameters such as current, voltage, pulse duration, and electrode gap, welders can achieve consistent, high-quality joints, ensuring structural integrity in final products.

– Key components and their functions

The success of resistance spot welding hinges on understanding its key components and their intricate roles. The primary system includes a power source that generates a high-current electrical pulse, concentrated through a small area via a specialized electrode. This focused energy creates a powerful heat input, melting and fusing the base materials together. The weld is controlled by precise timing and current intensity, ensuring a strong bond without excessive heat impact on surrounding areas.

In vehicle collision repair, especially after a fender bender, this precision becomes paramount. Auto collision centers rely on resistance spot welding to rebuild damaged panels with strength and integrity, matching the original manufacturer’s standards. The ability to precisely control welds minimizes material distortion and ensures structural integrity, crucial factors in restoring vehicles to their pre-collision condition.

Resistance spot welding is a versatile and precise technique that has transformed various industries. By understanding the fundamentals and leveraging advanced tips, welders can maximize efficiency, strengthen joints, and achieve consistent quality. This powerful method continues to evolve, ensuring its place as a go-to solution for many manufacturing processes.