Plastic welding is a critical skill for luxury car repair after collisions, as it ensures structural integrity and preserves vehicle value. Specialized techniques like heat fusion and ultrasonic welding are used to weld various plastics such as PP, PE, PVC, and PC, each with unique weldability. Skilled technicians employ these methods, along with precise tools, to restore vehicles like Mercedes-Benz to pre-accident condition, maintaining safety, performance, and aesthetics, ultimately leaving customers satisfied.

After a collision, the ability to weld plastics is crucial for repairing and restoring damaged items. Understanding which types of plastics can be welded post-collision opens up options for effective repairs. This article delves into the world of plastic welding after collisions, exploring common plastic materials and their weldability. We’ll guide you through techniques that enable successful plastic welding, ensuring lasting repairs. Discover how to navigate this process and choose the right approach for your specific needs.

- Understanding Plastic Welding After Collisions

- Common Types of Plastics and Their Weldability

- Techniques for Effective Plastic Welding Post-Collision

Understanding Plastic Welding After Collisions

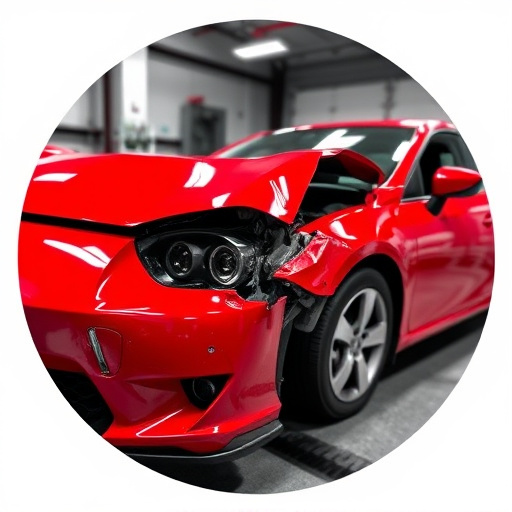

When a collision occurs, it’s not just metal that requires repair; plastics too are integral parts of modern vehicles. Understanding plastic welding after collisions is crucial for effective car repair services, especially in luxury vehicle repair. Unlike metal, which can be easily joined using traditional welding techniques, plastics demand a more meticulous approach. The process involves specialized equipment and skills to ensure the strength and integrity of the bond, maintaining the safety and structural integrity of the vehicle.

Plastic welding collision repairs are not just about fixing the exterior; they’re about restoring the car to its pre-accident condition. Skilled technicians in car repair shops employ various methods, such as heat fusion or adhesive bonding, to join like materials and fill in gaps left by damaged plastic parts. This ensures not only a visually appealing finish but also the long-term durability of the repairs, vital for maintaining the vehicle’s performance and value, whether it’s a regular sedan or a high-end luxury car.

Common Types of Plastics and Their Weldability

Plastics are a diverse group of materials, each with unique properties that affect their weldability. Common types include polypropylene (PP), polyethylene (PE), polyvinyl chloride (PVC), and polycarbonate (PC). These plastics are widely used in various applications, from car parts to household items, often as part of collision repair at a reliable collision repair center or auto repair near me.

While many plastics can be welded after a collision, the process varies significantly depending on the specific type. For instance, PP and PE are known for their good weldability due to their stable molecular structure, making them suitable for car dent removal and other automotive repairs. PVC, with its versatile nature, also offers excellent welding capabilities, while PC is prized for its impact resistance but may require specialized techniques for effective welding. Understanding these variations ensures that plastic welding after a collision is done efficiently and effectively at a trusted auto repair facility.

Techniques for Effective Plastic Welding Post-Collision

After a collision, effective plastic welding is crucial for restoring vehicles to their pre-accident condition, especially in parts like auto glass and dent repairs. Techniques such as heat fusion and ultrasonic welding are particularly effective for mercedes benz collision repair and other sophisticated vehicle makes. Heat fusion involves applying heat to melt the surfaces of the plastic, creating a strong bond once cooled. Ultrasonic welding, on the other hand, uses high-frequency sound waves to generate friction, melting the plastic and fusing it together.

These advanced methods ensure robust connections that match the original manufacturing quality. Skilled technicians employ these techniques in conjunction with precise measurement tools to achieve seamless results, making restored vehicles nearly indistinguishable from their pre-collision states. This level of craftsmanship is essential for maintaining vehicle safety and aesthetics, ensuring satisfied customers long after the repair process concludes.

In the event of a collision, understanding the potential for plastic welding can be key to effective vehicle repair. Different types of plastics require specific techniques and equipment, but with the right knowledge, it’s possible to achieve strong, lasting bonds. By recognizing the weldability of common automotive plastics and employing suitable methods, collision repair professionals can ensure structural integrity and aesthetic quality in repairs, ultimately enhancing customer satisfaction.