The auto body work industry is experiencing a tech-driven renaissance, driven by advancements like 3D printing and enhanced structural safety verification (SSV). These innovations improve precision, speed, and overall vehicle integrity while meeting evolving safety standards. SSV, in particular, goes beyond visual repairs to scrutinize hidden structural elements, ensuring comprehensive and reliable car dent repair and restoration. By integrating digital analysis, the industry aims to deliver top-tier quality, detect subtle issues early, and ultimately elevate its safety, precision, and reliability.

The future of auto body work is transforming, driven by demands for enhanced safety and sustainability. As vehicles evolve with advanced materials and designs, structural safety verification emerges as a cornerstone ensuring passenger protection in collisions. This article explores the shifting landscape of auto body work, delves into the critical role of structural safety verification, and examines how innovations in this domain are shaping a safer and more efficient future for the automotive industry.

- The Evolving Landscape of Auto Body Work

- The Role of Structural Safety Verification

- Embracing the Future: Innovations and Implications

The Evolving Landscape of Auto Body Work

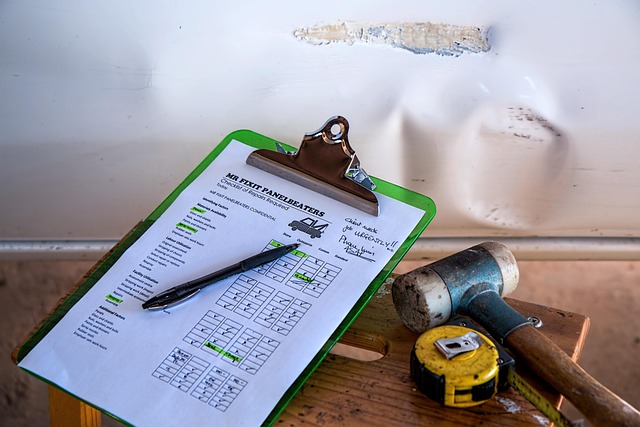

The landscape of auto body work is constantly evolving, driven by advancements in technology and a relentless pursuit of safety and efficiency. Traditional methods of repair and restoration are being supplemented by digital innovations such as 3D printing and advanced structural safety verification techniques. These breakthroughs not only enhance the precision and speed of bodywork services but also ensure superior structural integrity. Car owners now expect their vehicles to meet the highest safety standards, which has prompted the automotive industry to embrace more robust and reliable repair practices.

Auto painting, once a labour-intensive process, is now supported by computer-aided design (CAD) systems and robotic paint applications, enabling faster turnaround times and consistent quality. Similarly, tire services are no longer merely about replacement; they involve advanced wheel alignment technology and structural safety checks to optimize vehicle performance and driver safety. As vehicles become more interconnected and autonomous, the role of auto body shops is transforming from mere repair centres to hubs for sophisticated vehicle maintenance and technological enhancements, underpinned by a steadfast commitment to structural safety verification.

The Role of Structural Safety Verification

In the realm of auto body work, Structural Safety Verification (SSV) emerges as a game-changer, revolutionizing traditional vehicle repair services. This meticulous process ensures that every component of a car’s structure is examined and validated for its ability to withstand various forms of impact and stress. As vehicles continue to evolve with advanced materials and designs, SSV plays a pivotal role in maintaining optimal safety standards. It involves sophisticated technologies and expertise to assess not just the visible parts but also the hidden elements that contribute to a vehicle’s structural integrity.

By implementing rigorous SSV protocols, auto body shops can offer enhanced fender repair and car repair services. This verification process allows technicians to identify potential weak points or remnants of previous accidents, ensuring that every repair is precise and comprehensive. In today’s digital era, where innovation drives the automotive industry forward, structural safety verification acts as a crucial safeguard, fostering trust among customers who rely on top-notch vehicle repair services.

Embracing the Future: Innovations and Implications

The future of auto body work is an exciting prospect, driven by advancements in technology and a relentless pursuit of safety. Embracing innovative practices and tools, such as structural safety verification, will redefine how we approach car dent repair and vehicle restoration. This process involves meticulous digital analysis to ensure every component, from panels to frames, meets stringent safety standards, revolutionizing the traditional car restoration process.

By integrating structural safety verification, the industry can elevate its standards, making car restoration and body work more precise and reliable. It allows for efficient detection of potential issues, ensuring that even subtle dents or misalignments are addressed before they become major problems. This approach not only enhances the overall quality of repairs but also contributes to the longevity and structural integrity of vehicles, transforming the way we think about vehicle dent repair and fostering a new era of safety-first auto care.

As the automotive industry continues to evolve, structural safety verification emerges as a pivotal component in shaping the future of auto body work. By ensuring optimal structural integrity, this technology drives innovations that enhance vehicle safety and performance. Embracing these advancements is not just about staying ahead; it’s about creating a safer, more sustainable driving experience for generations to come. The focus on structural safety verification will undoubtedly revolutionize auto body work, making vehicles stronger, lighter, and better equipped to handle modern road conditions.