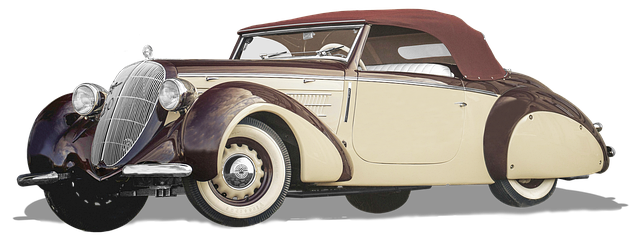

Mercedes High-Strength Steel (HSS) is a key material in automotive manufacturing, especially for performance models like Mercedes-Benz, known for its strength and durability. In case of frame straightening or collision repairs, skilled technicians employ specialized techniques to fix HSS components accurately, preserving structural integrity and safety. Advanced repair methods like laser welding prevent stress concentration failures, mitigating potential accidents and enhancing the longevity of Mercedes vehicles. After repairs, auto body painting with specialized tools ensures both durability and aesthetic appeal, maintaining the superior quality standards associated with the Mercedes brand.

Mercedes high-strength steel (MHSS) is renowned for its superior strength and durability, making it a key material in automotive construction. However, it’s not immune to failures, particularly at stress concentration points. This article delves into the intricacies of MHSS repair, exploring how skilled technicians can prevent catastrophic failures by addressing these vulnerable areas. By understanding the properties of MHSS and implementing effective repair techniques, we can enhance vehicle safety and structural integrity.

- Understanding Mercedes High-Strength Steel and Its Properties

- The Impact of Stress Concentration Failures on Vehicles

- Repair Techniques to Mitigate and Prevent Such Failures

Understanding Mercedes High-Strength Steel and Its Properties

Mercedes High-Strength Steel (HSS) is renowned for its exceptional strength and durability, making it a preferred material in automotive manufacturing, especially for high-performance vehicles like Mercedes-Benz models. This advanced steel grade offers superior resistance to deformation and impact damage compared to traditional steels. Its intricate microstructure, characterized by finely dispersed alloy phases, contributes to this remarkable strength.

When a Mercedes car undergoes a collision or requires frame straightening at a reputable car body shop or collision center, the integrity of its high-strength steel components is crucial. Skilled technicians employ specialized techniques for Mercedes high-strength steel repair, ensuring precision and minimal material disruption. This meticulous approach prevents stress concentration failures, where localized areas bear excessive load, leading to structural weaknesses. By understanding the unique properties of HSS, these professionals can effectively restore the vehicle’s structural integrity, guaranteeing safety and optimal performance upon completion of repairs at the collision center.

The Impact of Stress Concentration Failures on Vehicles

Stress concentration failures are a significant concern in the automotive industry, particularly for high-performance vehicles like Mercedes. These failures occur when stress is concentrated at specific points on a component, often due to design or manufacturing imperfections, leading to weakened structures and potential catastrophic failure during operation. In the context of Mercedes high-strength steel repair, addressing these issues is crucial to ensure vehicle safety and structural integrity.

When a vehicle experiences an automotive collision or undergoes severe stress, it can result in car damage repair that goes beyond mere aesthetics. Stress concentration points may weaken critical components, such as frames and suspension systems, making them more susceptible to failure during normal driving conditions. Effective Mercedes benz repair techniques, including the use of high-strength steel, are designed to mitigate these risks by redistributing stress evenly across components, enhancing their overall strength and durability, thus preventing potential accidents and ensuring a safer driving experience.

Repair Techniques to Mitigate and Prevent Such Failures

Repairs to Mercedes high-strength steel bodies require a meticulous approach to prevent stress concentration failures. These specialized repairs demand advanced techniques that cater to the unique properties of high-strength steel, which is commonly used in modern vehicle construction due to its superior strength and durability. Techniques such as laser welding and precision metal forming are instrumental in mitigating potential failure points. Laser welding, for instance, offers precise, clean, and strong joints by melting and fusing the metal directly, minimizing the risk of stress concentration at weld sites.

Auto body painting after repair is another critical step. Proper surface preparation and application techniques are essential to ensure the strength of the repaired area matches the surrounding body panel. Skilled technicians in reputable auto repair shops use specialized tools and paints designed for high-strength steel to achieve a durable, aesthetic finish while maintaining structural integrity. This comprehensive approach, combining advanced repair methods with meticulous painting procedures, is vital to prevent stress concentration failures, ensuring the longevity and safety of Mercedes vehicles.

Mercedes high-strength steel, with its exceptional properties, plays a pivotal role in modern vehicle construction. Understanding its unique characteristics and how stress concentration failures can impact these vehicles is essential. By employing specialized repair techniques that focus on preventing and mitigating such failures, we ensure the structural integrity and safety of Mercedes cars. Prompt action to address any damage or weakness in this high-performance steel can safeguard drivers and prevent potential accidents. Thus, prioritizing Mercedes high-strength steel repair is a game-changer in automotive maintenance.