Tesla's stringent Repair Quality Control (RQC) standards ensure every vehicle leaving their service centers meets high aesthetic and functional criteria, covering panel fit, paint quality, and complex system overhauls. Adhering to these guidelines requires rigorous inspections by qualified technicians, regular audits, and skill assessments. Effective Tesla RQC maintains the brand's reputation, safeguards vehicle value, and ensures customer satisfaction through continuous training and improvement.

Tesla vehicles are renowned for their cutting-edge technology and innovative design, but maintaining top repair quality control is essential for customer satisfaction. This article explores Tesla’s stringent repair quality control guidelines, offering insights into how service centers can meet these standards. From understanding the core principles to implementing robust procedures and fostering a culture of continuous improvement, we uncover best practices for ensuring every repair lives up to Tesla’s reputation for excellence.

- Understanding Tesla's Repair Quality Control Standards

- Implementing Effective Quality Control Procedures in Service Centers

- Continuous Improvement and Training for Optimal Repair Quality

Understanding Tesla's Repair Quality Control Standards

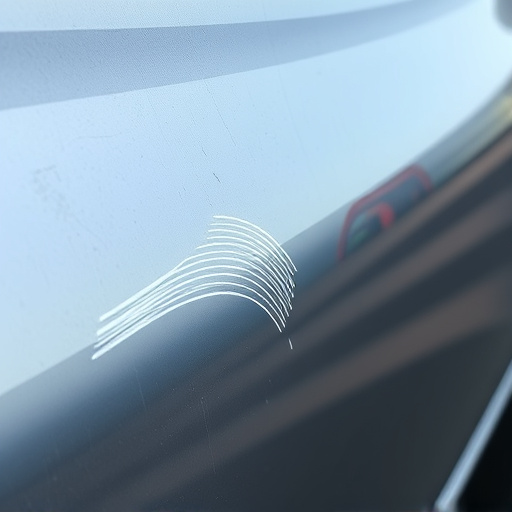

Tesla’s Repair Quality Control (RQC) standards are designed to ensure that every vehicle leaving their service centers meets the brand’s stringent aesthetic and functional criteria. This includes meticulous attention to detail during both repair and restoration processes, focusing on elements like panel fit, paint quality, and overall finish. RQC guidelines are comprehensive, encompassing various aspects of auto body and mechanical repairs, from fender repairs to complex system overhauls.

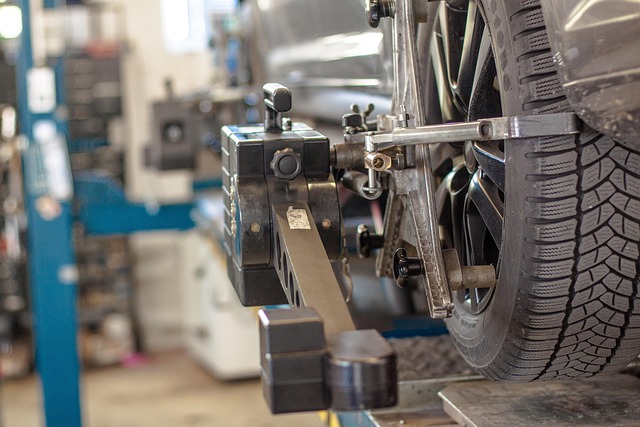

Service centers following these standards must maintain a rigorous inspection process, employing qualified technicians trained in Tesla’s specific repair methodologies. This involves regular audits and skill assessments to guarantee consistent quality across all operations, be it at a specialized auto body shop or a comprehensive auto repair shop. Adherence to RQC ensures that Tesla owners receive vehicles that not only look new but also perform optimally, reflecting the brand’s commitment to excellence in every repair process.

Implementing Effective Quality Control Procedures in Service Centers

Implementing robust quality control (QC) procedures is paramount for Tesla service centers to maintain the brand’s reputation and customer satisfaction. Effective QC ensures that every vehicle leaving the facility meets the highest standards, aligning with Tesla’s innovative technology and design. By establishing clear protocols, technicians can thoroughly inspect and address repairs, from intricate electrical systems to meticulous bodywork.

For instance, rigorous checks during each stage of a vehicle’s repair process—from initial assessment to final handover—are crucial. This includes not just functional tests but also aesthetic evaluations. After all, Tesla vehicles are renowned for their sleek design and premium finishes. Therefore, QC should encompass both auto dent repair and vehicle body repair, ensuring every scratch, dent, or misalignment is rectified perfectly. These meticulous procedures safeguard the vehicle’s value and integrity while guaranteeing a seamless ownership experience.

Continuous Improvement and Training for Optimal Repair Quality

Tesla service centers are held to a high standard when it comes to Tesla repair quality control, and continuous improvement is at the heart of this. Regular training sessions for technicians are essential to ensuring they stay up-to-date with the latest tools, techniques, and industry standards. This ongoing education not only covers technical aspects but also emphasizes customer service skills, fostering a culture that prioritizes both vehicle restoration and client satisfaction.

By embracing continuous improvement, Tesla aims to maintain its reputation for delivering top-tier car damage repair and collision repair shop services. Training programs often include hands-on workshops, digital tutorials, and peer-to-peer learning sessions. This comprehensive approach ensures that every repair, whether it’s an auto dent repair or a more complex job, is executed with precision and care, upholding Tesla’s commitment to excellence.

Tesla’s commitment to exceptional repair quality control is evident through its stringent guidelines and continuous improvement initiatives. By implementing effective procedures and rigorous training, service centers can ensure that repairs meet the brand’s high standards. Adhering to these best practices not only maintains customer satisfaction but also strengthens the overall reputation of Tesla as an innovator in electric vehicle technology. Optimizing repair quality control is a dynamic process, requiring ongoing evaluation and adaptation to stay ahead of industry trends and consumer expectations.