Glass corrosion, caused by moisture and chemicals, can significantly damage glass structures. To prevent this, glass setting materials like sealants and coatings are crucial for long-term protection. These products enhance durability and aesthetics, reducing replacement needs and repair costs in both residential and automotive applications. Best practices include thorough surface preparation and regular reapplication of protective layers to ensure optimal performance in various environments.

In the realm of glass craftsmanship, ensuring long-lasting durability is paramount, especially at the edges. This article explores the critical role of glass setting materials in preventing corrosion, a process that can weaken and compromise structural integrity. We delve into the science behind glass corrosion, examining its causes and impact. Subsequently, we uncover various glass setting materials, their types, and the benefits they offer. Understanding application techniques and best practices is essential for achieving longevity in glass structures, ensuring they remain vibrant and secure.

- Understanding Glass Corrosion and Its Impact

- Exploring Glass Setting Materials: Types and Benefits

- Effective Application and Best Practices for Longevity

Understanding Glass Corrosion and Its Impact

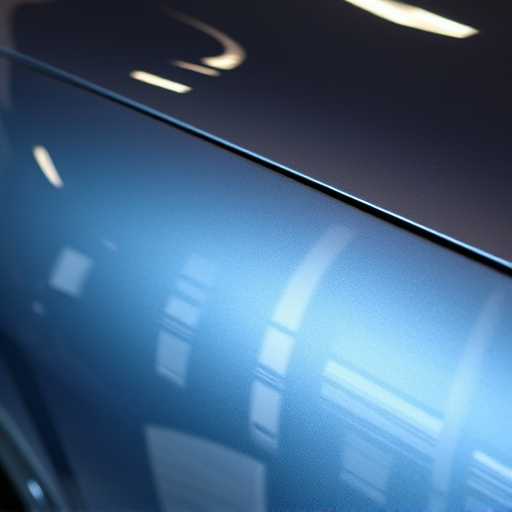

Glass corrosion, often overlooked, can be a significant issue that impacts the durability and aesthetics of glass structures. It occurs when moisture or certain chemicals come into contact with the edge of the glass, leading to deterioration over time. This phenomenon is especially pertinent in environments with high humidity or where water exposure is frequent, such as in cars and buildings undergoing auto painting or collision repair services. The impact of corrosion can range from visible discoloration and etch marks to more severe structural damage, compromising the integrity of the glass panel.

Understanding the causes and effects of glass corrosion is crucial when selecting appropriate glass setting materials for various applications. By choosing products designed to prevent corrosion, such as specialized sealants and coatings, car repair services and collision repair shops can offer long-lasting solutions that protect against moisture intrusion. This not only enhances the structural integrity of glass but also ensures visual appeal, maintaining the original condition even in challenging conditions, thus reducing the need for frequent replacements or costly repairs.

Exploring Glass Setting Materials: Types and Benefits

Glass setting materials play a pivotal role in enhancing the durability and aesthetic appeal of glass applications, especially along delicate edges. These specialized compounds are designed to prevent corrosion, ensuring the longevity of glass installations in various industries, from automotive to architectural. Exploring different types of glass setting materials offers a multitude of benefits, catering to specific needs and environmental conditions.

One of the primary advantages is their ability to create a robust bond with glass surfaces, forming a protective barrier against moisture, chemicals, and extreme temperatures—a critical factor in preventing corrosion. Some materials are formulated to be compatible with car bodywork services, providing exceptional durability for vehicle repair services and even enhancing the visual appeal through specialized auto body painting techniques. With these materials, professionals can effectively navigate challenging applications, ensuring a seamless finish that stands the test of time.

Effective Application and Best Practices for Longevity

The effective application of glass setting materials is paramount to preventing corrosion around glass edges, ensuring longevity in both residential and automotive settings. Best practices include meticulous preparation of the surface, cleaning it thoroughly to remove any debris or contaminants that could interfere with adhesion. This step is crucial as even the slightest impurity can compromise the protection offered by the glass setting material.

Once the surface is ready, applying the material evenly across the edges is essential. For optimal results in auto bodywork or car body restoration, a thin yet consistent layer should be targeted, focusing on exposed areas prone to moisture ingress. Regular maintenance also plays a significant role; reapplication of protective coatings can extend the life of glass settings, especially in harsh environments. This proactive approach, incorporating proper application techniques and timely re-coating, is key to preserving the integrity of glass edges in both everyday use and specialized auto maintenance scenarios.

Glass setting materials play a pivotal role in preventing corrosion around glass edges, ensuring longevity and aesthetic appeal. By understanding the impact of corrosion and exploring the diverse types of setting materials available, professionals can make informed decisions to safeguard glass structures. Effective application and adherence to best practices are key to reaping these benefits, ultimately preserving the beauty and integrity of glass installations for years to come. Choosing the right glass setting materials is a game-changer in the industry, fostering robust and corrosion-resistant solutions.