PDR techniques have evolved significantly, combining traditional craftsmanship with modern technology for precise and effective vehicle dent repairs. These advancements, including paintless dent repair (PDR), automated tools, and advanced composite materials, streamline auto body work, reduce costs, and restore vehicles to their original condition while maintaining structural integrity. While initial investment in innovative PDR methods is higher, they enhance productivity, cut labor needs, and offer superior results in auto body shops.

In the ever-evolving field of damage assessment, Proper Damage Repair (PDR) techniques play a pivotal role in restoring vehicles to their pre-incident condition. This article delves into the evolution of PDR methods, comparing traditional practices with innovative modern approaches. Through a historical lens, we explore foundational techniques that laid the groundwork for today’s advanced repair strategies. Then, we analyze the benefits and considerations of each method, providing insight for professionals navigating this dynamic landscape of PDR techniques.

- Understanding Traditional PDR Techniques: A Historical Perspective

- Embracing Innovation: The Rise of Modern PDR Approaches

- Comparative Analysis: Benefits and Considerations for Each Method

Understanding Traditional PDR Techniques: A Historical Perspective

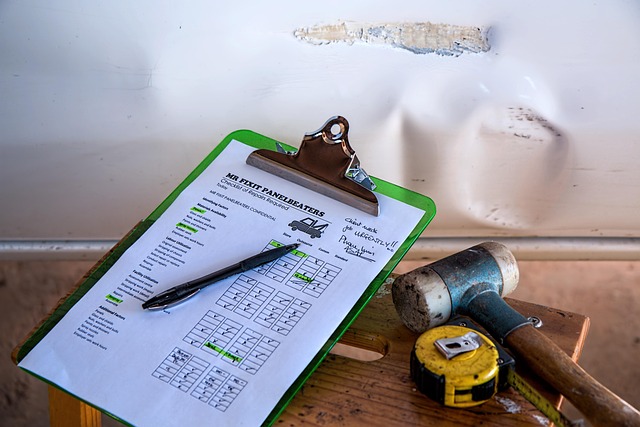

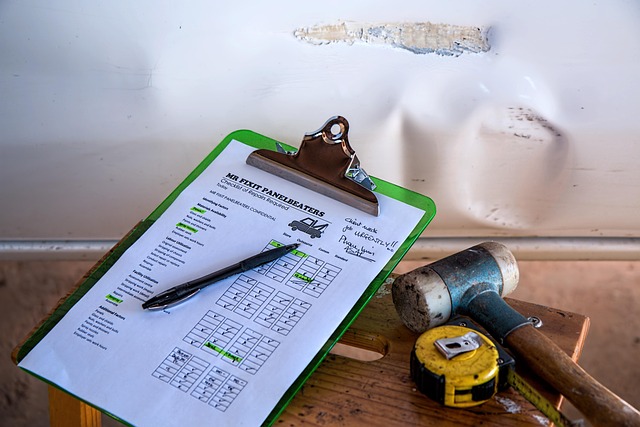

Traditional PDR techniques have evolved over decades, reflecting the historical progression of auto body work and automotive collision repair. At their core, these methods focus on manual, skill-driven processes to restore damaged vehicles to their original condition. Historically, this involved techniques such as hammering, clamping, and dry sanding, where skilled technicians meticulously reshaped metal panels, straightened dents, and restored surfaces to perfection. These methods required a deep understanding of materials science, human dexterity, and years of hands-on experience.

The advent of modern technology has led to innovations in PDR techniques, but the foundational principles remain rooted in this historical practice. Today’s auto body work incorporates advanced tools like pneumatic hammers, precision mallets, and specialized sanding equipment, enhancing efficiency while still demanding a high level of craftsmanship. This blend of traditional knowledge and innovative tools allows for precise, effective repair of a wide range of car bodywork services, ensuring vehicles not only look like new but also maintain structural integrity.

Embracing Innovation: The Rise of Modern PDR Approaches

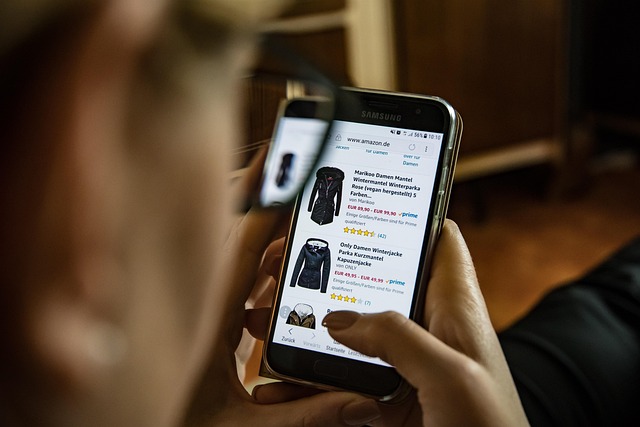

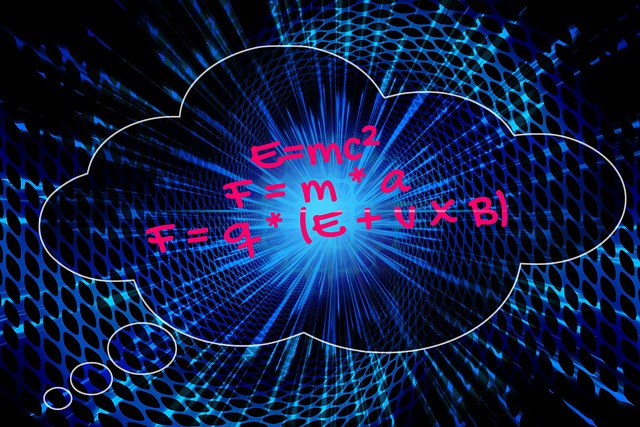

The world of vehicle dent repair (PDR) has witnessed a significant transformation with the advent of modern, innovative techniques. Traditional methods, once the go-to for auto body shops and car enthusiasts alike, are now being challenged by cutting-edge approaches that promise faster, more efficient repairs. This shift towards innovation is driven by several factors, including advancements in technology, rising customer expectations, and a growing demand for cost-effective solutions without compromising quality.

Modern PDR techniques leverage state-of-the-art tools and equipment to deliver precise, seamless repairs, often reducing the time and cost associated with traditional methods. For instance, the use of advanced paintless dent repair (PDR) tools allows technicians to gently work their way into and out of dents, minimizing damage to the car body shop’s finish. This not only streamlines auto body services but also ensures that vehicles can be restored to their original condition, if not better, using innovative techniques like precision tooling, fiberglass repairs, and advanced composite materials—all contributing to a more sustainable and efficient vehicle dent repair process.

Comparative Analysis: Benefits and Considerations for Each Method

In the realm of vehicle repair and restoration, Polished Drum Rotation (PDR) techniques have emerged as a game-changer in the automotive body shop industry. When comparing traditional PDR methods to innovative approaches, several key benefits and considerations come to light. Traditional PDR involves manually rotating a drum to apply polish, which is effective for removing minor dents and scratches from vehicle bodywork. This time-tested method is appreciated for its precision, allowing skilled technicians to achieve seamless results in the auto painting process. However, it can be labor-intensive and may not be as efficient for larger or more complex damage, potentially extending repair times.

On the other hand, innovative PDR techniques leverage advanced tools and technology to streamline the process. These modern methods often incorporate automated systems that enhance speed and consistency, making them ideal for high-volume auto body shops. By employing sophisticated equipment, such as robotic arms and advanced polishers, innovative PDR can reduce repair times significantly. Moreover, these techniques are versatile, capable of handling a broader range of dents and scratches in the vehicle bodywork, from shallow to deep. While initial investment costs for innovative systems may be higher, the long-term benefits include increased productivity, reduced labor requirements, and improved overall efficiency in the automotive body shop environment.

In comparing traditional and innovative PDR techniques, it’s clear that modern approaches offer significant advancements. While historical methods have laid a solid foundation, embracing innovation allows for enhanced efficiency, precision, and adaptability in today’s evolving landscape. When considering the benefits and considerations of each, organizations can make informed decisions to leverage the most suitable PDR techniques for their specific needs, ultimately driving better outcomes and staying competitive in the market.