Implementing robust safety measures in repair facilities goes beyond regulatory compliance, aiming to maximize equipment longevity and minimize failures. Well-maintained protocols reduce incidents, protect critical tools, and prevent structural damage during precision processes like fender repair. Prioritizing safety includes adhering to manufacturer guidelines, staff training, regular maintenance checks, clean workspaces, proper handling of hazardous materials, inspections, and mandatory PPE. These measures significantly mitigate risks associated with heavy-duty machinery, enhancing efficiency in car body restoration while fostering a safer environment. In the auto maintenance industry, prioritizing repair facility safety is key to preserving equipment integrity, streamlining operations, minimizing downtime, and enhancing customer satisfaction.

In the heart of every efficient repair facility lies a cornerstone of success: robust safety measures. This isn’t just about compliance; it’s a proactive defense against equipment damage and catastrophic failures. By prioritizing safety, facilities mitigate risks, preserve machinery integrity, and extend the lifespan of their critical tools. This article explores how established safety protocols and consistent practices are the guardians of repair facility efficiency and equipment longevity.

- Understanding the Impact of Safety Measures on Equipment Preservation

- Essential Safety Protocols for Repair Facility Operations

- Strategies to Minimize Damage and Prolong Equipment Lifespan through Consistent Safety Practices

Understanding the Impact of Safety Measures on Equipment Preservation

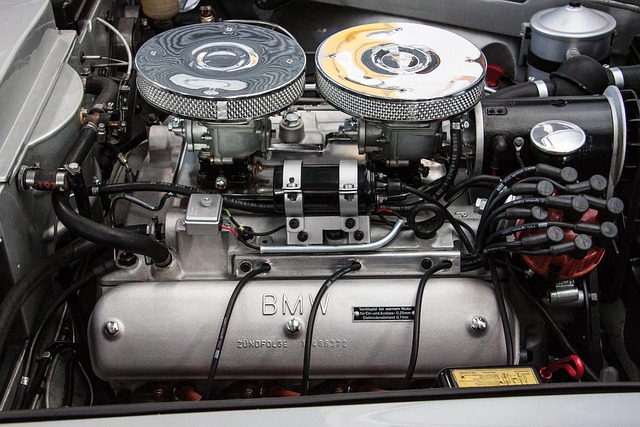

Implementing robust safety measures within repair facilities is not merely a regulatory requirement; it’s a strategic move to preserve equipment longevity and minimize failures. When accidents or negligence occur, the consequences can be severe—from costly equipment damage to productivity losses. A well-maintained, safe workspace promotes efficiency by reducing incidents that may lead to extensive repairs or even replacement of critical tools. For instance, a paintless dent repair station equipped with proper safety gear ensures technicians are protected during operations, extending the lifespan of the machinery and maintaining its optimal performance.

Similarly, car restoration processes heavily rely on meticulous precision and safety protocols. Proper training and adherence to safety standards in fender repair, for example, prevent accidents that could result in structural damage or malfunctioning of specialized equipment. By fostering a culture of safety, repair facilities can create an environment conducive to preventing equipment damage, ultimately contributing to sustained operational effectiveness and reducing the need for frequent, costly repairs.

Essential Safety Protocols for Repair Facility Operations

In any repair facility, safety should be the top priority to prevent equipment damage and failures. Essential safety protocols include implementing strict adherence to manufacturer guidelines for all tools and equipment, ensuring proper training and certification for staff handling machinery, and establishing regular maintenance checks. These measures are crucial in mitigating risks associated with heavy-duty machinery commonly used in vehicle body repair or car bodywork services, thereby enhancing the overall efficiency of car body restoration processes.

Moreover, maintaining a clean, organized workspace free from debris is vital. Proper handling of hazardous materials, such as chemicals and waste, must be strictly enforced to protect both employees and equipment. Regular safety inspections should be conducted to identify potential risks, while using personal protective equipment (PPE) becomes mandatory for all staff members. Such precautions not only safeguard against accidental damage but also contribute to a safer environment for everyone involved in the car body repair process.

Strategies to Minimize Damage and Prolong Equipment Lifespan through Consistent Safety Practices

In the realm of auto maintenance and vehicle repair, establishing robust safety practices within a repair facility is paramount for minimizing equipment damage and prolonging its lifespan. By fostering a culture of safety, facilities can ensure that every task, from routine automotive repair to complex overhaul, is executed with meticulous care. This involves regular inspections to identify potential hazards, proper training for staff on safe handling procedures, and adherence to manufacturer guidelines.

Implementing these strategies not only prevents costly equipment failures but also enhances the overall efficiency of the facility. Consistent safety practices enable smooth operations, reduce downtime, and ultimately contribute to better customer satisfaction. A well-maintained repair facility is a testament to the balance between skilled craftsmanship and meticulous attention to safety, ensuring that every vehicle leaves the premises in top condition.

In conclusion, prioritizing repair facility safety is paramount in preventing equipment damage and failures. By implementing essential protocols and consistent safety practices, facilities can significantly extend the lifespan of their equipment. Investing in these measures not only safeguards assets but also fosters a culture of efficiency and reliability within the repair environment. Repair facility safety is more than just a protocol; it’s a strategic approach that ensures sustained operational excellence.