Efficient commercial vehicle repair is vital for business continuity, minimizing downtime, and enhancing customer satisfaction. Standardized inspection protocols, advanced diagnostic tools, regular technician training, digital record-keeping, and clear communication streamline the process from initial assessment to final repairs, including auto body restoration and dent removal. These modern methods optimize fleet management, reduce costly breakdowns, and promote proactive maintenance, ultimately benefiting both repair shops and fleet managers.

Boosting efficiency in commercial vehicle repair is key to minimizing downtime and maximizing revenue. This article presents 10 actionable tips tailored for workshops aiming to optimize their operations. From streamlining diagnostic procedures through standardized protocols and advanced tools, to implementing intelligent spare parts management strategies like JIT inventory, these practices enhance productivity. Additionally, we explore the benefits of strategic workshop layout design and integrating digital technology for seamless record-keeping and communication. Discover how these techniques can revolutionize your commercial vehicle repair process.

- Streamlining Diagnostic Procedures

- – Standardize inspection protocols for consistent and efficient troubleshooting.

- – Implement advanced diagnostic tools to pinpoint issues swiftly.

Streamlining Diagnostic Procedures

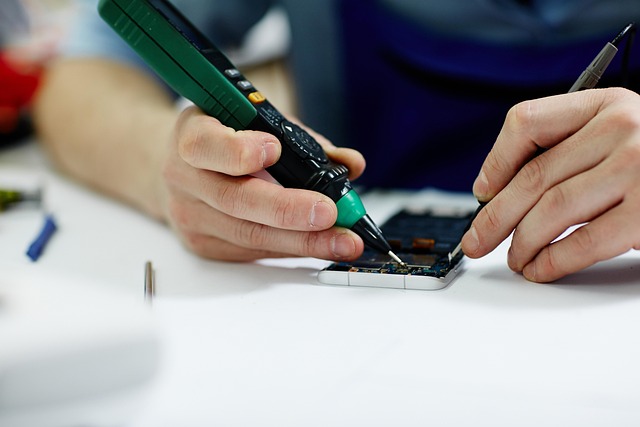

In the realm of commercial vehicle repair, efficiency is key to keeping businesses running smoothly and minimizing downtime. Streamlining diagnostic procedures is a vital step in achieving this. By implementing standardized protocols and utilizing advanced diagnostic tools, repair shops can significantly reduce the time spent identifying issues. This involves regular training for technicians on the latest equipment and common problems specific to commercial vehicles. A structured approach ensures that each step of the diagnosis is thorough yet swift, allowing for quicker resolution and enhancing overall efficiency in auto body repair.

Moreover, integrating digital systems for record-keeping and communication can further optimize the process. Efficient diagnostic methods not only benefit the repair shop but also ensure that fleet managers receive accurate, timely information about their vehicles’ health. This proactive approach fosters a culture of preventive maintenance, reducing the likelihood of costly breakdowns and minimizing disruptions in commercial vehicle operations. Remember that every minute saved in diagnosis translates to faster turnaround times for auto body restoration, ultimately enhancing customer satisfaction.

– Standardize inspection protocols for consistent and efficient troubleshooting.

Standardized inspection protocols are a cornerstone for achieving consistent and efficient commercial vehicle repair. By establishing clear, structured processes, repair teams can systematically diagnose issues across various makes and models. This approach ensures that every step, from initial visual inspections to detailed technical assessments, is conducted in a uniform manner. Such standardization facilitates faster troubleshooting, as technicians become adept at quickly identifying patterns and anomalies. Moreover, it reduces errors and miscommunications, enabling repairs to be completed more accurately and within scheduled timelines.

Implementing standardized protocols also streamlines the repair process, benefiting both workshops and customers. When all staff are trained on these protocols, they can efficiently collaborate, ensuring that no stone is left unturned during vehicle assessments. This efficiency translates into cost savings for businesses and peace of mind for commercial fleet owners, knowing their vehicles are in capable hands. Additionally, standardization paves the way for better inventory management and parts procurement, further optimizing the entire repair ecosystem, from initial assessment to final handiwork—including areas like car paint repair and vehicle dent repair.

– Implement advanced diagnostic tools to pinpoint issues swiftly.

In today’s fast-paced world, efficient commercial vehicle repair is paramount for businesses to maintain their operations. Implementing advanced diagnostic tools is a game-changer in this regard. These sophisticated devices enable mechanics to swiftly and accurately identify issues within complex automotive systems. By leveraging modern technology, auto body shops can significantly reduce downtime, as quick diagnostics lead to faster repairs.

Moreover, these tools often provide detailed reports, ensuring that every problem is comprehensively understood before proceeding with any fix, including specialized tasks like auto dent repair or vehicle restoration. Unlike traditional methods, this advanced approach streamlines the entire process, making it more cost-effective and convenient for both businesses and their vehicles, whether in need of minor adjustments or major overhauls.

By streamlining diagnostic procedures through standardized inspection protocols and leveraging advanced tools, commercial vehicle repair shops can significantly enhance efficiency. These strategies not only save time but also ensure consistent and accurate troubleshooting, ultimately leading to faster repairs and improved customer satisfaction in the dynamic world of commercial vehicle maintenance.