Aftermarket auto glass, to be trusted by both consumers and professionals alike, undergoes rigorous independent testing for structural integrity, optical clarity, and safety performance. This void certification ensures it meets OEM quality standards, providing reliable and safe solutions for vehicle repair, restoration, or straightening, thus enhancing driver and passenger safety across various weather conditions.

Aftermarket auto glass plays a vital role in vehicle safety, performance, and aesthetics. When installing or replacing auto glass, proper certification is crucial to ensure quality and compliance. This article delves into the world of aftermarket auto glass certification, highlighting its significance for both consumers and professionals. We’ll explore the certification process, safety standards, and best practices to navigate this essential aspect of the automotive industry.

- Understanding Aftermarket Auto Glass and Its Certification

- The Importance of Void Certification for Safety and Quality

- Navigating the Process: Getting Certified for Aftermarket Auto Glass

Understanding Aftermarket Auto Glass and Its Certification

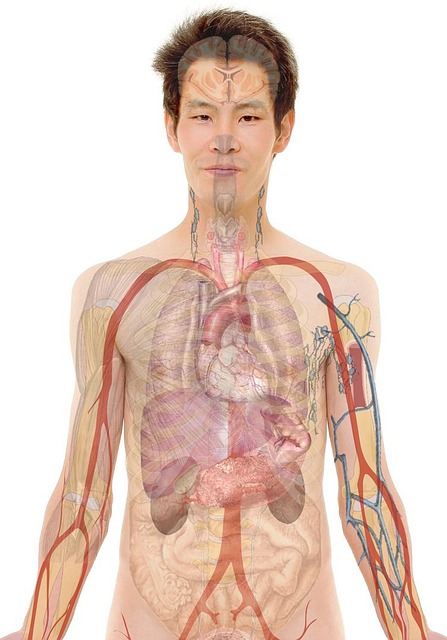

Aftermarket auto glass refers to replacement windshields, side windows, and rear windows that are manufactured by companies other than the original equipment manufacturer (OEM). While OEM glass is designed and tested to meet specific safety standards, aftermarket glass must also adhere to strict quality and safety criteria. Certification plays a crucial role in ensuring this consistency. Independent testing agencies evaluate the structural integrity, optical clarity, and safety performance of aftermarket auto glass, issuing certificates that verify their compliance with industry standards.

This certification process is vital for consumers and professionals alike. It reassures buyers that the replacement glass will provide the same level of protection as the original equipment, contributing to vehicle safety and visibility. For those involved in bumper repair, vehicle restoration, or frame straightening, using certified aftermarket glass can streamline their work, ensuring they meet industry standards while offering customers reliable and safe solutions.

The Importance of Void Certification for Safety and Quality

When it comes to aftermarket auto glass, void certification plays a pivotal role in ensuring safety and maintaining quality standards. This rigorous process verifies that the glass is free from defects and meets specific criteria, which is paramount for the structural integrity and clear visibility of your vehicle’s windows. In an industry where precision matters, void certification acts as a safeguard against hidden flaws that could compromise both driver safety and the overall performance of auto body work.

For consumers seeking reliable vehicle repair or paintless dent repair services, understanding this certification process is crucial. It assures them that the aftermarket glass being installed is not just visually appealing but also functions optimally in various weather conditions and driving scenarios. By adhering to these standards, experts in auto body work can deliver top-notch results, enhancing both the aesthetics and safety of a vehicle, thereby fostering peace of mind for the occupants behind the wheel.

Navigating the Process: Getting Certified for Aftermarket Auto Glass

Navigating the Process: Getting Certified for Aftermarket Auto Glass

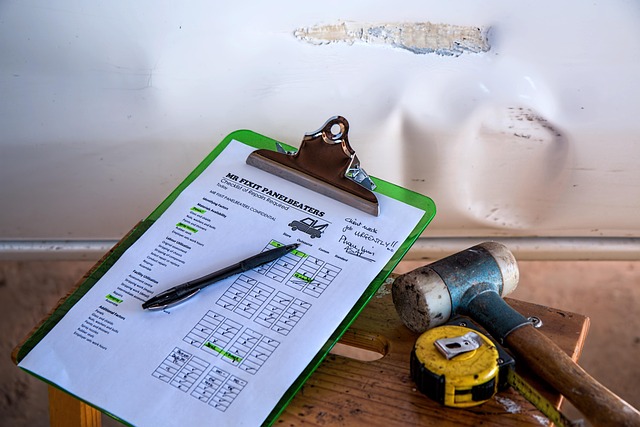

The journey to obtaining certification for aftermarket auto glass involves several steps designed to ensure quality and safety. It begins with understanding the specific requirements set by industry standards, such as those established by organizations like the National Automotive Glass Standard (NAGS) or similar bodies. These guidelines cover various aspects, including material composition, manufacturing processes, and installation techniques.

Once familiarized with the standards, individuals or businesses engaged in aftermarket auto glass must undergo training programs to gain the necessary expertise. This training often includes hands-on workshops and theoretical sessions that delve into topics like proper measurement, cutting, and fitting techniques. For example, a Mercedes Benz repair shop looking to certify its aftermarket glass would ensure that every technician involved is adept at handling vehicle paint repair and car paint repair processes, ensuring minimal damage during the replacement or installation phases.

Aftermarket auto glass plays a crucial role in vehicle safety, and void certification is an essential step to ensure quality. By understanding the certification process and its significance, auto industry professionals can navigate the path to reliable glass solutions. This comprehensive guide has outlined the key aspects of aftermarket auto glass certification, empowering businesses to make informed decisions and provide drivers with safe, high-quality replacements.