3D vehicle scanning technology has revolutionized automotive industry standards by delivering precise digital models of vehicles' structures, capturing millions of data points. This innovation empowers mechanics and body shops to conduct thorough assessments from every angle, detecting subtle discrepancies in frames, panels, and components. By offering an accurate, non-invasive method for detailed inspections, 3D scanning ensures tailored, efficient, and reliable collision repair processes, enhancing the accuracy and efficiency of repairs and proving invaluable for bodywork assessments and dent repair.

In today’s digital era, 3D vehicle scanning is revolutionizing the automotive industry by providing a detailed view of vehicle structures. This advanced technology captures intricate dimensions and shapes, enabling thorough inspections for structural issues that might be missed through traditional methods. By understanding 3D scanning principles and their application in detecting defects, professionals can ensure higher quality standards and safety. Explore the benefits and diverse applications of this game-changer technology in the automotive sector.

- Understanding 3D Vehicle Scanning Technology

- The Role of 3D Scanning in Detecting Structural Defects

- Benefits and Applications in the Automotive Industry

Understanding 3D Vehicle Scanning Technology

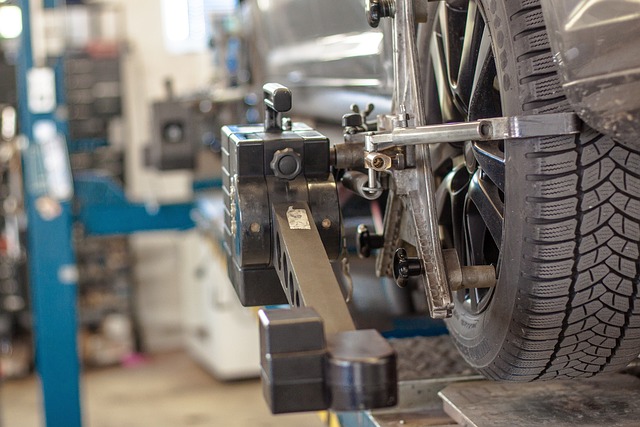

3D vehicle scanning technology has revolutionized the automotive industry by providing a detailed and accurate view of a vehicle’s structure. This innovative process involves using specialized equipment to capture millions of data points, creating a precise digital model of the vehicle. By generating a three-dimensional representation, mechanics and body shops can meticulously assess every angle and contour of a car, truck, or motorcycle.

This technology offers numerous benefits for car repair services and collision repair processes. It enables professionals in vehicle body shops to detect even the slightest discrepancies in a vehicle’s frame, panels, and components. With 3D scanning, technicians can quickly identify structural issues that might be overlooked during manual inspections. This advanced method ensures that every repair is precisely tailored to the specific needs of the vehicle, leading to more efficient and reliable car repair services.

The Role of 3D Scanning in Detecting Structural Defects

The integration of 3D scanning technology has revolutionized the way structural defects in vehicles are identified and addressed. This advanced technique offers an accurate and non-invasive method to capture detailed digital representations of vehicle surfaces, allowing for thorough inspections that surpass traditional manual examinations. By creating precise 3D models, every curve, contour, and potential anomaly becomes visible, enabling auto body specialists to detect even the subtlest imperfections.

This technology is particularly valuable in car bodywork services and collision centers, where identifying hidden damage or misalignments is crucial for effective repair. 3D vehicle scanning facilitates a comprehensive assessment of car damage repair, ensuring that no structural issues go unnoticed. From minor cracks to more significant deformities, the detailed scans provide an objective baseline for repairs, enhancing the accuracy and efficiency of the entire process.

Benefits and Applications in the Automotive Industry

3D vehicle scanning offers numerous benefits and applications in the automotive industry. This advanced technology allows for a detailed digital representation of vehicles, providing an unparalleled level of precision when examining structural integrity. By capturing every curve, contour, and angle, 3D scanning enables professionals to detect even the subtlest defects or damage that might be overlooked during manual inspections.

One of its key advantages is its versatility in various automotive processes. It’s invaluable for car bodywork assessments, helping to identify panel misalignments, weld issues, or signs of previous repairs. Moreover, 3D scanning aids in vehicle restoration projects by creating accurate models for reference and ensuring that every component is precisely replicated. Even in cases of vehicle dent repair, this technology assists technicians in accurately measuring and estimating the extent of damage, leading to more efficient and effective remediation.

3D vehicle scanning technology is transforming automotive maintenance and safety. By providing detailed, three-dimensional models of vehicles, this innovative process allows for more accurate detection of structural issues that might be overlooked during traditional inspections. The benefits are clear: faster diagnostics, reduced repair times, and improved overall vehicle performance. As 3D scanning becomes more accessible, it promises to play a pivotal role in enhancing safety standards and revolutionizing the way we maintain our vehicles.