The auto repair industry is evolving rapidly, driven by technological advancements and higher consumer expectations. To stay ahead of the competition, auto shops must adopt modern trends in body shop services, particularly advanced welding techniques. These techniques, including laser and robotic welding, offer unparalleled precision, structural integrity, and efficiency for repairs and custom fabrications. By investing in such innovations, auto body shops can provide high-quality work, cater to diverse customer needs, shorten repair times, enhance safety and aesthetics, and ultimately achieve superior customer satisfaction while remaining competitive in the dynamic market.

In today’s auto industry, where efficiency and precision reign supreme, advanced welding techniques have become a game changer for auto shops. The evolving landscape of repair and maintenance demands methods that go beyond traditional practices. This article explores why adopting cutting-edge welding technologies is no longer an option but a necessity. From enhanced structural integrity to reduced material waste, these techniques revolutionise vehicle repairs, ensuring durability and cost-effectiveness.

- The Evolving Landscape of Auto Repair and Maintenance

- Benefits of Advanced Welding Techniques in Auto Shops

- Implementing and Mastering Cutting-Edge Welding Technologies

The Evolving Landscape of Auto Repair and Maintenance

The auto repair and maintenance industry is constantly evolving, driven by technological advancements and shifting consumer expectations. In today’s digital era, auto shops must adapt to stay competitive. The traditional model of simple repairs and quick fixes is no longer sufficient; customers now demand high-quality, precise, and efficient body shop services. This shift has led to a growing emphasis on advanced welding techniques as the backbone of modern auto bodywork.

Vehicle restoration has become a specialized art, requiring skilled technicians who can meticulously fuse parts together. Advanced welding techniques enable shops to offer state-of-the-art bodywork, ensuring vehicles not only look their best but also maintain structural integrity. As such, investing in these methods is no longer an option but a necessity for any auto shop aiming to thrive in this dynamic landscape.

Benefits of Advanced Welding Techniques in Auto Shops

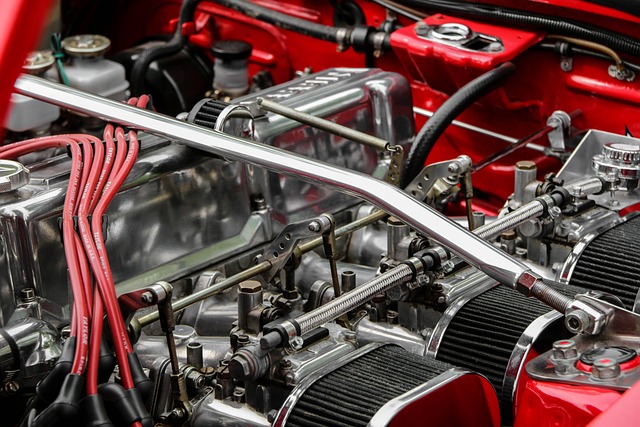

Advanced welding techniques offer a multitude of benefits for auto shops, elevating their capabilities and services. These modern methods allow for precise and strong welds, which is crucial in automotive repairs and custom fabrications. With advanced tools like laser and robotic welding, shops can achieve unparalleled accuracy, ensuring every join is secure and durable. This precision translates to better structural integrity, a key aspect of safe and reliable vehicles.

Furthermore, these techniques enable auto body restoration and car damage repair with minimal distortion or alteration to the original parts. In the case of car scratch repair, advanced welding ensures subtle yet effective solutions, preserving the car’s aesthetic appeal. It also facilitates complex custom designs and modifications, catering to clients seeking unique vehicle transformations. Overall, embracing advanced welding techniques empowers auto shops to deliver higher-quality work, satisfy diverse customer needs, and stay ahead in a competitive market.

Implementing and Mastering Cutting-Edge Welding Technologies

In today’s competitive auto industry, advanced welding techniques are no longer a luxury but an imperative for any top-tier collision center or auto body service provider. Implementing cutting-edge technologies in welding offers significant advantages, including improved precision, enhanced structural integrity, and faster repair times. These modern methods allow technicians to master intricate car body restoration tasks with remarkable efficiency.

Auto body shops that invest in advanced welding techniques can deliver superior results for customers seeking top-quality auto body services. By embracing innovations like laser welding, robotically-assisted systems, or automated flux core processes, these facilities not only meet but exceed industry standards while ensuring every repair is both safe and aesthetically pleasing.

In today’s rapidly evolving automotive landscape, staying ahead requires embracing advanced welding techniques. These technologies not only enhance repair precision and quality but also streamline shop operations, reducing downtime for vehicles. By investing in cutting-edge welding methods, auto shops can offer more efficient and reliable services, ensuring customer satisfaction and maintaining their competitive edge in the market.