Tesla's global Gigafactories, strategically located and adhering to strict Tesla factory specifications, drive innovative electric vehicle production. Utilizing advanced robotics, automation, and sustainable energy sources, these facilities manufacture models like the Model 3 and Model Y with meticulous quality control. With vertical integration of components and in-house repair services, Tesla ensures optimal performance and timely deliveries, showcasing its commitment to excellence and environmental responsibility.

“Unveiling the Inner Workings of Tesla’s Production Magic: A Deep Dive into Factory Specifications for Model 3 and Y. Tesla’s manufacturing prowess is a cornerstone of its success, with state-of-the-art facilities like Fremont and Berlin Gigafactories leading the charge. This article explores the intricate assembly process, from robot-assisted production to sustainable practices, that transform raw materials into sleek, electric vehicles. Discover how Tesla’s factory specifications contribute to both cutting-edge vehicle design and environmental stewardship.”

- Production Facilities and Location

- – Overview of Tesla's manufacturing hubs

- – Details on the Fremont and Berlin Gigafactories

Production Facilities and Location

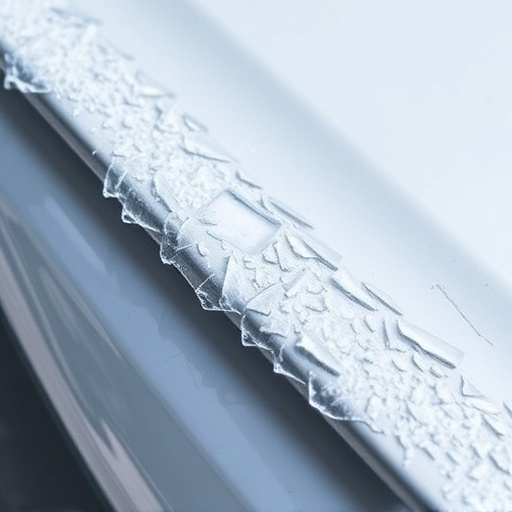

Tesla’s production facilities play a pivotal role in the company’s global operations and are designed to meet the demanding standards of its electric vehicle models, including the Tesla Model 3 and Model Y. The auto collision center within these factories is a state-of-the-art facility dedicated to ensuring each vehicle undergoes rigorous quality control checks. Here, any car damage repair or fender repair needed prior to final assembly is meticulously executed, contributing to the overall excellence of Tesla’s manufacturing process.

With multiple locations strategically chosen worldwide, Tesla has established a robust production network. These facilities are not just assembly lines but highly efficient centers that combine cutting-edge technology with a skilled workforce. The primary focus on location selection includes proximity to key markets and access to sustainable energy sources, reflecting Tesla’s commitment to efficiency and environmental sustainability in its factory specifications.

– Overview of Tesla's manufacturing hubs

Tesla’s manufacturing hubs are a testament to its innovative approach to vehicle production. The company operates several state-of-the-art factories globally, collectively known as Gigafactories, designed to streamline the production process and reduce costs while adhering to stringent Tesla factory specifications. These facilities aren’t just assembly lines; they are crucibles where cutting-edge technology meets sustainable practices.

The Gigafactories produce both the Model 3 and Model Y, incorporating advanced manufacturing techniques such as robotization, automation, and vertical integration of key components like batteries. This not only ensures consistent quality control but also facilitates timely delivery of these popular electric vehicles. In terms of car repair services and auto bodywork, Tesla’s facilities are equipped to handle routine maintenance and extensive repairs, ensuring the longevity and optimal performance of their vehicles.

– Details on the Fremont and Berlin Gigafactories

Tesla’s Fremont and Berlin Gigafactories stand as beacons of innovation in automotive manufacturing. The Fremont facility, located in California, has been a cornerstone of Tesla production since its inception, housing advanced assembly lines tailored to produce both the Model 3 and Model Y. This plant is renowned for its efficiency, employing cutting-edge robotics and automated systems to streamline the production process. As one of Tesla’s flagship factories, Fremont prioritizes sustainability and eco-friendly practices, aligning with the company’s broader mission.

In contrast, Tesla’s Berlin Gigafactory represents a strategic expansion into Europe. This state-of-the-art facility boasts impressive capacity for both battery production and vehicle assembly. Its design incorporates advanced safety measures and sustainable energy sources, ensuring efficient operations while minimizing environmental impact. The Berlin plant is pivotal in supporting global demand for the Model 3 and Model Y, facilitating faster delivery times and enhancing Tesla’s market reach, all while showcasing the company’s unwavering commitment to superior vehicle manufacturing standards, including effective dent removal and meticulous frame straightening techniques to ensure pristine vehicle condition post-production, even after potential vehicle collision repair scenarios.

Tesla’s commitment to sustainable transportation is reflected in the meticulous specifications of its factories, particularly the Fremont and Berlin Gigafactories. These facilities are designed to streamline production for the Model 3 and Y, leveraging advanced technologies and renewable energy sources. By focusing on efficiency and environmental stewardship, Tesla continues to set a new standard in the automotive industry, ensuring the consistent delivery of high-quality electric vehicles worldwide.