Tesla repair scanning is a groundbreaking method for maintaining electric vehicle (EV) reliability and safety. Using advanced diagnostic tools, auto collision centers can perform system-level analysis on Tesla vehicles, identifying potential issues before they cause costly breakdowns. This proactive approach extends vehicle lifespans, enhances driver safety, and improves customer satisfaction by minimizing unexpected repairs and inconvenience. With AI and machine learning integration predicted in the future, Tesla repair scanning is set to revolutionize not just Tesla, but all vehicle maintenance, ensuring optimal performance and peace of mind for owners.

Tesla repair scanning is transforming the way electric vehicle (EV) systems are maintained, ensuring optimal performance and reliability. This article explores the innovative process of Tesla repair scanning, its benefits for proactive system monitoring, and how it minimizes repeat failures. We delve into best practices and future trends, highlighting the impact of advanced diagnostics on EV repairs. By understanding Tesla repair scanning, technicians can enhance customer satisfaction through more efficient and effective maintenance strategies.

- Understanding Tesla Repair Scanning: Unveiling the Process

- Benefits of Proactive Scanning for System Reliability

- Best Practices and Future Trends in Tesla Repair Scanning

Understanding Tesla Repair Scanning: Unveiling the Process

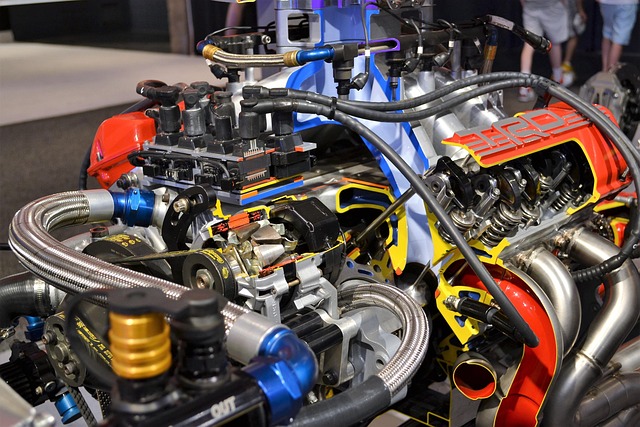

Tesla repair scanning is a groundbreaking process that revolutionizes vehicle maintenance. It’s more than just a diagnostic tool; it’s a system-level analysis designed to uncover potential issues before they become costly failures. By employing advanced technology, auto collision centers can delve into the intricate networks of Tesla vehicles, identifying subtle anomalies that might go unnoticed during routine checks.

This process involves scanning various systems within the car, including electrical components, sensors, and software modules. Data is meticulously analyzed to detect any discrepancies or performance indicators suggesting potential problems. Unlike traditional auto body work focused on visible repairs, Tesla repair scanning takes a proactive approach, addressing hidden issues that could lead to future breakdowns. This not only extends the lifespan of the vehicle but also ensures drivers enjoy a safer, more reliable driving experience.

Benefits of Proactive Scanning for System Reliability

Proactive Tesla repair scanning is a game-changer when it comes to ensuring system reliability and preventing repeat failures. By implementing regular and thorough scanning procedures, workshops can identify potential issues at an early stage, long before they escalate into costly and time-consuming repairs. This approach allows for timely intervention, minimizing the impact on both vehicle performance and customer satisfaction.

The benefits extend beyond immediate cost savings. Regular scanning also helps in maintaining the overall health of the electric vehicle’s systems, ensuring they function optimally. Moreover, it reduces the likelihood of unexpected breakdowns, which are not only inconvenient but can also pose safety risks, especially for Tesla owners who rely on advanced driver-assistance systems (ADAS). With proactive measures in place, collision repair services and car scratch repairs become less frequent, contributing to a smoother ownership experience.

Best Practices and Future Trends in Tesla Repair Scanning

The evolution of Tesla repair scanning practices is a testament to the company’s commitment to enhancing vehicle reliability and customer satisfaction. Best practices involve utilizing advanced diagnostic tools that can pinpoint issues with precision, ensuring repairs are effective and comprehensive. This methodical approach, combined with a deep understanding of Tesla’s unique software and hardware architectures, is key to preventing repeat system failures.

Looking ahead, future trends in Tesla repair scanning promise even greater efficiency. The integration of AI and machine learning algorithms will enable auto collision repair shops to predict potential issues before they occur, revolutionizing the way auto repair shops conduct business. As these technologies mature, we can expect more proactive maintenance routines, further reducing the instances of costly and time-consuming system failures in both Tesla and conventional vehicles. This shift towards predictive maintenance holds immense potential for enhancing overall vehicle performance and owner peace of mind.

Tesla repair scanning is a game-changer in ensuring the long-term reliability of electric vehicle systems. By proactively identifying potential issues through advanced diagnostic tools, repair technicians can prevent repeat system failures and enhance customer satisfaction. As technology advances, best practices evolve, fostering a more efficient and effective Tesla repair process. Embracing these trends will undoubtedly revolutionize the automotive industry, setting a new standard for electric vehicle maintenance.