Sound deadening materials are essential for enhancing acoustic comfort in various settings, from cars to industrial spaces. Professionals can choose between fiberglass insulation for low-frequency sounds and foam-based materials for high-frequency noise absorption. Effective installation requires meticulous visual inspection, accurate measurement techniques like sound level meters and impedance measurements, as well as precise adhesive bond assessments using tools like pressure sensors and heat guns. Attention to detail during installation in collision centers ensures maximum sound insulation benefits.

Inspecting the effectiveness of sound deadening materials installation is crucial for achieving optimal noise reduction. This comprehensive guide explores how to assess the quality of sound deadening material integration in various settings. We delve into different types of sound deadening materials and their applications, practical methods to evaluate installation integrity, and advanced measurement techniques to ensure top-tier performance. By understanding these steps, you’ll be equipped to verify the effectiveness of sound deadening solutions for your specific needs.

- Understanding Sound Deadening Materials: Types and Their Applications

- Assessing Installation Quality: Practical Methods and Tools

- Testing Effectiveness: Measurement Techniques for Optimal Performance

Understanding Sound Deadening Materials: Types and Their Applications

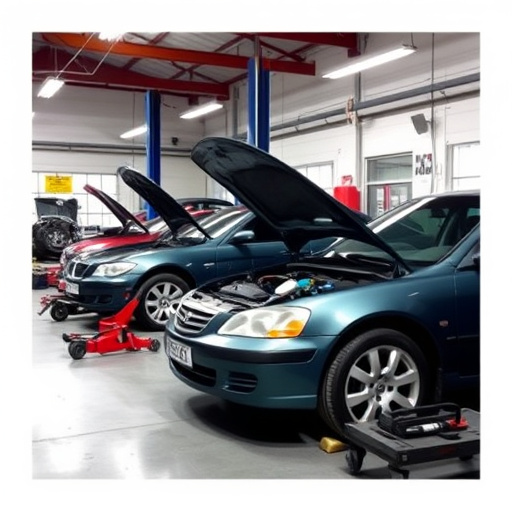

Sound deadening materials are an essential component in improving the acoustic properties of various spaces, from automotive interiors to industrial settings. These materials are designed to absorb and dissipate sound energy, thereby reducing noise levels and enhancing overall audio quality. The market offers a diverse range of sound deadening options tailored for specific applications. For instance, flexible sound deadening mats and pads are commonly used in auto collision repair centers to line car bodies, reducing vibrations and minimizing noise during bumper repair processes.

Different types of sound deadening materials have distinct properties and uses. Fiberglass insulation is a popular choice due to its lightweight nature and effectiveness in blocking low-frequency sounds. On the other hand, foam-based materials excel at absorbing high-frequency noises, making them ideal for treating resonating chambers or enhancing the acoustics in recording studios. Understanding these variations enables professionals in collision repair centers to select the most suitable sound deadening solutions for various projects, ensuring optimal performance and quieter environments.

Assessing Installation Quality: Practical Methods and Tools

When evaluating the effectiveness of sound deadening materials installation, assessing the quality of the work is paramount. Start by visually inspecting the car bodywork for any gaps, misalignments, or uneven surfaces. Proper installation should result in a seamless fit, with minimal visible gaps between panels and components. Using tools like torches, tape measures, and precision gauges can help identify discrepancies that may affect sound deadening performance.

Additionally, examining the integrity of the adhesive bonds is crucial. Strong, secure bonds are essential for effective sound insulation. Tools such as pressure sensors and heat guns can be employed to test bond strength and ensure they meet manufacturer recommendations. In an auto collision center or during auto body work, meticulous attention to detail during installation significantly contributes to achieving optimal noise reduction levels in vehicles.

Testing Effectiveness: Measurement Techniques for Optimal Performance

To assess the effectiveness of sound deadening materials, it’s crucial to employ precise measurement techniques. The goal is to quantify noise reduction levels accurately, ensuring optimal performance. One common method involves using a sound level meter, a device that measures decibels (dB), to compare noise levels before and after installation. By placing the meter at various points within the space, you can identify areas needing additional attention or verify successful deadening in hard-to-reach spots.

Another valuable technique is the use of impedance measurement, which analyzes how sound waves interact with the material. This method, often employed in auto body painting and auto collision centers for quality control of sound deadening in auto repair services, provides insights into the material’s ability to absorb and dissipate energy, ultimately contributing to a quieter environment.

Inspecting the effectiveness of sound deadening material installation is a crucial step in ensuring optimal noise reduction. By understanding the types and applications of these materials, assessing installation quality with practical methods, and employing measurement techniques, you can verify their performance and make necessary adjustments. This process is essential for achieving tranquil indoor spaces, especially in noisy environments, thereby enhancing overall comfort and quality of life.