Quality control (QC) inspections are essential in the automotive industry for maintaining high standards, ensuring customer satisfaction, and preventing post-service issues. By implementing rigorous QC strategies, auto repair shops can detect and rectify flaws early, building client trust, reducing return visits, and fostering long-term loyalty through improved service quality. These measures include staff training, standardized checklists, advanced equipment, regular audits, and feedback sessions, ultimately enhancing business success through positive word-of-mouth referrals.

Quality control (QC) inspection is a vital process that prevents return visits and issues, enhancing customer satisfaction. This article delves into the profound role of QC in ensuring products meet high standards. We explore how rigorous inspections prevent defects, save costs, and foster client loyalty. Furthermore, we provide actionable tips for businesses to implement effective QC strategies, ultimately revolutionizing their quality management practices and reducing future problems. By understanding and leveraging quality control inspection, companies can significantly improve their operations.

- Understanding Quality Control Inspection: Its Role in Ensuring Customer Satisfaction

- Preventing Return Visits and Issues: The Direct Impact of Quality Control

- Implementing Effective QC Strategies: Tips for Businesses to Enhance Quality and Reduce Costs

Understanding Quality Control Inspection: Its Role in Ensuring Customer Satisfaction

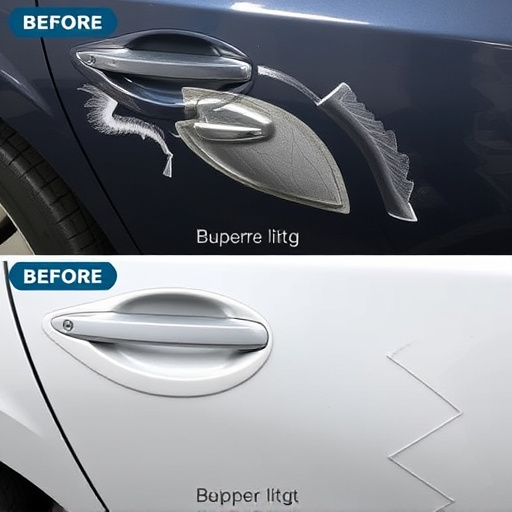

Quality control inspection plays a pivotal role in ensuring customer satisfaction in the automotive industry, particularly when it comes to intricate processes like paintless dent repair and car body repair. This meticulous practice involves a comprehensive evaluation of products or services before they are delivered to the end-user. By implementing rigorous standards, businesses can guarantee that only flawless work leaves their premises, minimizing the likelihood of post-purchase issues.

In the context of automotive repair, a quality control inspection ensures that every car body repair is executed flawlessly. It involves scrutinizing the repair process, from material selection to final finishing, to confirm it aligns with industry standards and customer expectations. This proactive approach not only prevents return visits due to subpar work but also fosters trust between the repair shop and its clients, ensuring a positive experience and encouraging repeat business for future automotive repair needs, whether it’s paintless dent repair or more complex car body repairs.

Preventing Return Visits and Issues: The Direct Impact of Quality Control

Implementing robust quality control inspection processes within a car body shop or auto painting facility is pivotal in preventing return visits and mitigating post-service issues. This proactive approach serves as a cornerstone for maintaining customer satisfaction and fostering long-term trust. By meticulously examining every aspect of a car body restoration project, from the precision of repairs to the accuracy of color matching during auto painting, potential flaws can be identified and rectified before the vehicle leaves the premises.

This meticulous attention to detail ensures that clients receive a high-quality, defect-free service on their first attempt, eliminating the need for costly reworks or repeat visits. Ultimately, the direct impact of quality control extends beyond reduced customer frustration; it strengthens the reputation of the shop, builds brand loyalty, and contributes to the overall success and profitability of the business by fostering positive word-of-mouth referrals.

Implementing Effective QC Strategies: Tips for Businesses to Enhance Quality and Reduce Costs

Implementing robust quality control (QC) strategies is a powerful way for businesses, especially in the automotive industry, to enhance their operations and reduce costs significantly. A well-structured QC process ensures that every product or service delivered meets the required standards, minimizing errors and defects. For collision centers and auto repair shops offering services like frame straightening and auto glass repair, this is crucial.

Start by training staff to recognize even subtle imperfections and establishing clear inspection protocols. Standardized checklists can help streamline the process, ensuring no detail is missed. Investing in advanced equipment for precise measurements and visual inspections further refines the QC process. Regular audits and feedback sessions can also catch emerging issues early on, allowing businesses to adapt their strategies promptly. These proactive measures not only prevent return visits but also build trust with customers, fostering long-term loyalty.

Quality control (QC) inspection is a powerful tool that businesses can leverage to enhance customer satisfaction and reduce return visits and issues. By implementing robust QC strategies, companies can identify and rectify defects early on, ensuring products or services meet high standards. This proactive approach not only saves costs but also fosters trust and loyalty among customers. Embracing effective QC practices is essential for any business aiming to thrive in a competitive market by delivering consistent quality.