OEM guidelines emphasize blending panels as a key strategy in collision repair, aiming for seamless integration of car body parts while preserving both aesthetics and structural integrity. This technique, recommended for modern vehicle designs, efficiently hides minor damage, enhances safety by eliminating weak points, and ensures high-quality, professional repairs that maintain vehicle value. By accurately matching color and texture, blending panels offers a durable, visually appealing solution for dent repair, reducing the risk of future collisions.

OEM guidelines strongly advocate for blending adjacent panels in automotive manufacturing. This strategy, far from being a mere aesthetic choice, serves a critical function in enhancing structural integrity and collision prevention. By seamlessly integrating panels, automakers ensure uniform strength and rigidity across vehicles’ bodies, minimizing the risk of blisters, cracks, and other deformities under stress. Adhering to these guidelines offers substantial benefits, including improved safety, reduced manufacturing defects, and enhanced overall vehicle quality.

- Understanding OEM Guidelines for Panel Blending

- The Impact of Blending Panels on Collision Prevention

- Best Practices and Benefits of Adhering to Guidelines

Understanding OEM Guidelines for Panel Blending

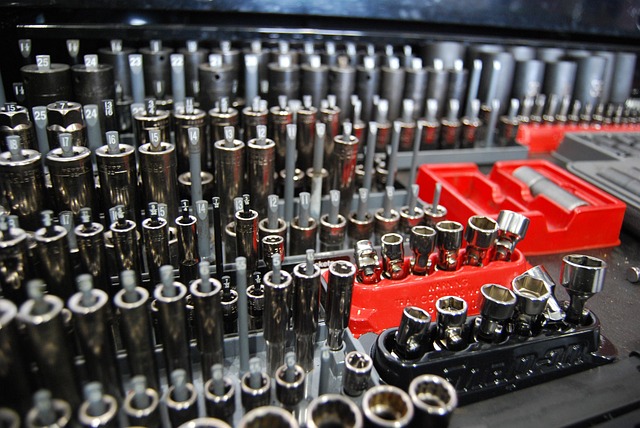

OEM guidelines for panel blending emphasize seamless integration of adjacent panels during collision repair, ensuring vehicles maintain their original aesthetic appeal and structural integrity. These guidelines are designed to standardize practices across industries, promoting consistent quality in auto painting and vehicle repair processes.

By recommending blending panels instead of simply substituting new parts, OEM protocols acknowledge the intricate nature of modern vehicle design. Each panel is meticulously crafted to contribute to the overall aesthetics and performance of the vehicle. Blending adjacent panels allows for precise color matching and smooth transitions, effectively repairing damage without compromising the car’s original appearance. This approach, crucial in vehicle paint repair, not only enhances the final finish but also ensures the safety and longevity of the vehicle structure.

The Impact of Blending Panels on Collision Prevention

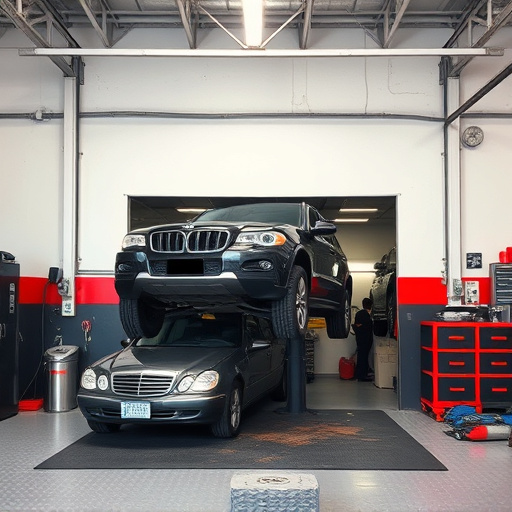

Blending panels is a key strategy recommended by OEM guidelines to prevent collisions and ensure vehicle safety. When adjacent panels on a car body are seamlessly blended together, it creates a smooth transition in both appearance and structural integrity. This technique is particularly crucial in auto body restoration and paintless dent repair processes, where even the slightest imperfection can compromise the overall aesthetics and strength of the vehicle.

By blending panels, technicians can effectively mask minor dents, scratches, or defects, creating an invisible repair that preserves the car’s original look. Moreover, this method enhances collision prevention by maintaining the structural stability of the vehicle body. The seamless integration of panels reduces potential weak points where collisions could occur, making the vehicle safer and more resilient during accidents.

Best Practices and Benefits of Adhering to Guidelines

Adhering to OEM (Original Equipment Manufacturer) guidelines for blending adjacent panels is a best practice that offers numerous benefits in vehicle dent repair and auto body services. By following these recommendations, collision centers can ensure superior quality and durability in their work. Blending involves seamlessly merging repaired areas with the surrounding original panel, eliminating visible signs of damage or repairs. This technique not only enhances aesthetics but also strengthens the structural integrity of the vehicle’s body, crucial for safety and long-term performance.

In terms of benefits, adhering to guidelines results in a more consistent and professional finish. It minimizes the risk of collisions between panels during the repair process, preventing new dents or damage that could compromise the overall quality. Moreover, it allows for better color matching and texture continuity, making repaired areas virtually indistinguishable from the original parts. These practices are essential for maintaining the vehicle’s value and ensuring customer satisfaction in collision centers.

OEM guidelines recommend blending adjacent panels primarily to mitigate the impact of collisions. By seamlessly integrating panels, vehicles become less susceptible to visible damage in the event of a crash, enhancing safety and reducing repair costs. Adhering to these guidelines not only ensures structural integrity but also contributes to a more aesthetically pleasing vehicle design. This practice is a game-changer in the automotive industry, fostering both collision prevention and cost-effective repairs.