Squeeze-type resistance spot welding is a specialized automotive collision repair technique that fuses metal components precisely without intense heat or melting, creating localized heat through electric current to bind metals at a microscopic level. Ideal for vehicle dent repair and intricate work like Mercedes Benz repair, it offers minimal heat damage and preserves component integrity. Top-quality results require strict adherence to best practices, including thorough cleaning, consistent pressure and energy application, and efficient cooling post-weld.

“Uncovering the transformative power of Squeeze-Type Resistance Spot Welding (SRSW) in the realm of repairs, this article offers a comprehensive guide. SRSW, a specialized technique within resistance spot welding, presents unique advantages for precise and durable fixings. From its mechanism of applying heat through controlled pressure to its diverse applications, we explore how it ensures robust bonds across various materials. Discover best practices to master this method, ensuring top-quality repairs with enhanced efficiency.”

- Understanding Squeeze-Type Resistance Spot Welding: A Basic Overview

- Advantages and Applications in Repair Work

- Best Practices for Achieving Quality Results with This Technique

Understanding Squeeze-Type Resistance Spot Welding: A Basic Overview

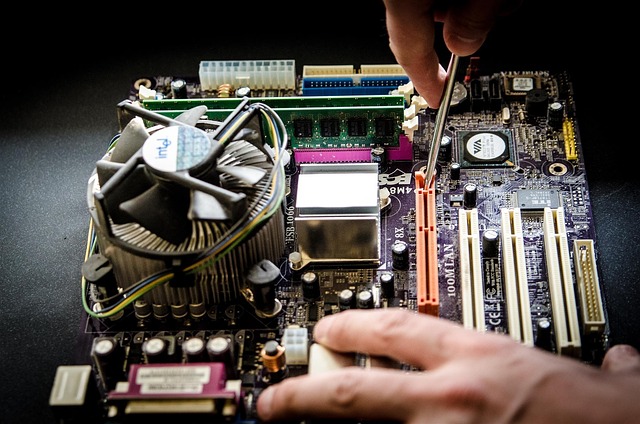

Squeeze-type resistance spot welding is a specialized technique used in automotive collision repair and car bodywork services to join metal components with precision and strength. Unlike traditional welding methods, this process doesn’t involve intense heat or melting; instead, it utilizes pressure and electrical energy to fuse metals at a microscopic level. A small, focused electric current passes through the materials, creating a concentrated heat that binds them together, ensuring a strong and durable joint.

This innovative approach is particularly beneficial for vehicle dent repair, as it allows for precise manipulation of metal without causing excessive heat damage. The method is fast, efficient, and highly controlled, making it ideal for complex car bodywork services where precision and integrity of the original structure are paramount.

Advantages and Applications in Repair Work

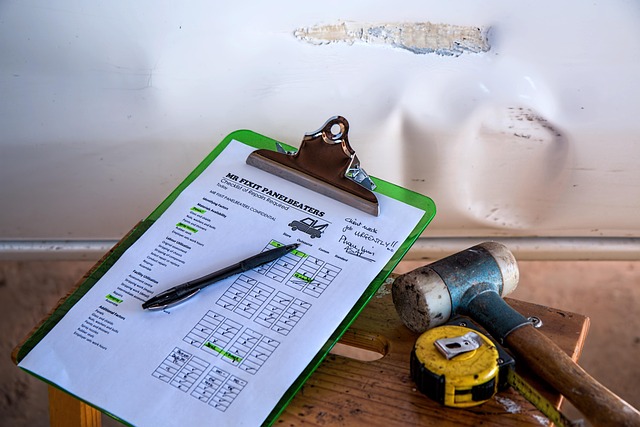

Squeeze-type resistance spot welding offers several advantages that make it a preferred method for repair work, especially in the automotive industry. This precise technique allows for accurate and controlled welds, making it ideal for intricate and detailed repairs. By applying pressure and heat to specific points on the metal, this method can join dissimilar materials without affecting the surrounding area, which is crucial for preserving the original integrity of components during car restoration or Mercedes Benz repair processes.

Its versatility extends to a wide range of applications, from repairing damaged panels in auto painting to reinforcing structural joints. This technology is particularly beneficial for complex geometric shapes and tight spaces where traditional welding methods might struggle. Its non-destructive nature ensures minimal distortion, making it a valuable tool for maintaining the aesthetic quality of vehicles during restoration projects.

Best Practices for Achieving Quality Results with This Technique

Achieving quality results with squeeze-type resistance spot welding requires adherence to best practices. First, ensure proper preparation of the weld area in the auto body shop. This includes cleaning the surfaces thoroughly to remove any debris or contaminants that could hinder the bonding process. Preheating the components slightly can also help improve the overall strength of the weld.

During the welding process, maintaining consistent pressure and energy levels is crucial. Using the right tool for the job, with precise control over the squeeze force, ensures a strong bond without damaging the surrounding materials. In vehicle paint repair or car damage repair scenarios, this technique allows for accurate, localized heating, minimizing heat impact on adjacent areas. Proper cooling after the weld is key to preventing warping or distortion, ensuring the final product meets high standards in any auto body shop.

Squeeze-type resistance spot welding offers a precise and efficient repair solution, enhancing structural integrity. Its advantages, including minimal material distortion and strong welds, make it ideal for various applications. By adhering to best practices, such as using the correct equipment and maintaining optimal parameters, technicians can consistently achieve high-quality results. This technique’s versatility and effectiveness in resistance spot welding make it a valuable toolset addition for repair work across industries.