The introduction of electronic measuring equipment has transformed auto body restoration and collision repair industries by offering unprecedented precision, accuracy, and data-driven insights. These advanced tools streamline workflows, enhance productivity, reduce waste, and ensure consistent outcomes, minimizing human error and maximizing efficiency in operations like panel alignment and digital inventory tracking. By leveraging electronic measuring equipment, shops can achieve higher quality control standards, reduce rework, maintain superior customer satisfaction, and guarantee the longevity of repaired vehicles.

In today’s competitive retail landscape, shops are continually seeking ways to enhance precision, streamline operations, and ensure quality control. Adopting electronic measuring equipment is a game-changer in this regard. Unlike traditional methods, these advanced tools offer unparalleled accuracy and consistency, revolutionizing how businesses operate. This article explores the multifaceted benefits of integrating electronic measuring equipment into retail shops, focusing on improved precision, streamlined workflows, and reduced human error.

- Enhancing Precision and Accuracy with Electronic Measuring Equipment

- Streamlining Workflows and Boosting Productivity in Shops

- Ensuring Quality Control and Reducing Human Error

Enhancing Precision and Accuracy with Electronic Measuring Equipment

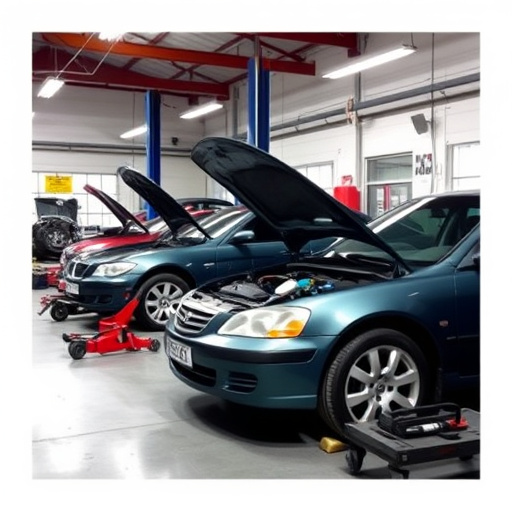

The introduction of electronic measuring equipment has brought about a significant shift in the way shops, particularly those specializing in auto body restoration and automotive collision repair, conduct their business. This technology offers an unparalleled level of precision and accuracy that was once unimaginable with traditional tools. With features like digital readouts, automated calculations, and advanced sensors, these devices minimize human error, ensuring every measurement is consistent and reliable.

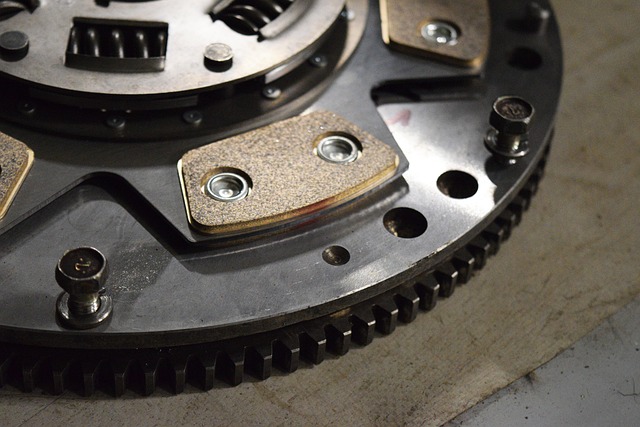

For professionals in vehicle collision repair, this means achieving meticulous results during the restoration process. Whether it’s measuring panel gaps, aligning frames, or checking clearances, electronic measuring equipment provides data-driven insights that enable precise adjustments. This attention to detail not only guarantees customer satisfaction but also streamlines the overall repair process, leading to faster turnaround times and more efficient workflows in auto body restoration shops.

Streamlining Workflows and Boosting Productivity in Shops

In today’s competitive market, efficient workflows are key to success in any shop, be it an auto collision repair facility or a car dealership offering comprehensive car repair services. Electronic measuring equipment revolutionizes traditional methods by providing precise and quick measurements, thereby streamlining operations. For instance, advanced laser measuring tools can quickly capture dimensions of car bodywork, eliminating manual errors and saving significant time. This enhances overall productivity as technicians can focus on more complex tasks, ensuring faster turnaround times without compromising quality.

By implementing electronic measuring equipment, shops can achieve remarkable efficiency gains. These devices enable accurate measurements for panel alignment during auto collision repair, reducing the need for multiple attempts and minimizing material waste. Moreover, they facilitate easier tracking of inventory and stock levels, as digital records provide detailed insights into usage patterns, leading to better resource management in car repair services.

Ensuring Quality Control and Reducing Human Error

The adoption of electronic measuring equipment has revolutionized the way shops conduct quality control in various sectors, including vehicle repair services and car restoration. Traditional manual measurements are prone to human error, which can lead to inconsistent results and subpar work. With electronic tools, such as digital calipers and laser measures, precision is significantly improved. These devices provide accurate, real-time data, ensuring every measurement is exact, regardless of the operator’s skill level. This level of consistency is vital in industries like automotive collision repair, where precise measurements are crucial for safe and effective repairs.

By utilizing these advanced tools, shops can streamline their processes, reduce rework, and maintain higher standards. Electronic measuring equipment plays a pivotal role in minimizing human errors that often occur during manual tasks, especially in demanding environments like car restoration projects. This technology empowers technicians to deliver reliable results, ensuring customer satisfaction and the longevity of restored or repaired vehicles.

Electronic measuring equipment has revolutionized the retail landscape, offering shops unparalleled precision, efficiency, and quality control. By adopting these innovative tools, businesses can streamline workflows, reduce human error, and ultimately enhance customer satisfaction. The benefits are clear: improved accuracy in product measurements, faster turnaround times, and a competitive edge in an ever-demanding market. Investing in electronic measuring equipment is a strategic move that pays dividends in both the short and long term.