Digital measuring systems, leveraging technologies like laser scanners and 3D imaging, have transformed car restoration and paintless dent repair by offering unprecedented precision and accuracy. These systems eliminate human error, ensure consistent data, and optimize resource allocation, waste reduction, and turnaround times compared to traditional methods. In today's digital era, they streamline auto painting and collision repair processes, providing superior outcomes with faster service times, making them invaluable assets for businesses in these sectors.

In today’s competitive market, investing in digital measuring systems is no longer an option but a necessity. These innovative solutions are transforming industries by offering unprecedented precision and accuracy in measurements, outpacing traditional methods. From manufacturing to healthcare, digital solutions streamline workflows, reduce errors, and save valuable time. Moreover, they provide rich data insights, enabling continuous improvement and better decision-making. Discover how these systems are revolutionizing processes and driving success across various sectors.

- Precision and Accuracy in Digital Measuring Systems

- – The role of technology in achieving meticulous measurements

- – Advantages over traditional methods

Precision and Accuracy in Digital Measuring Systems

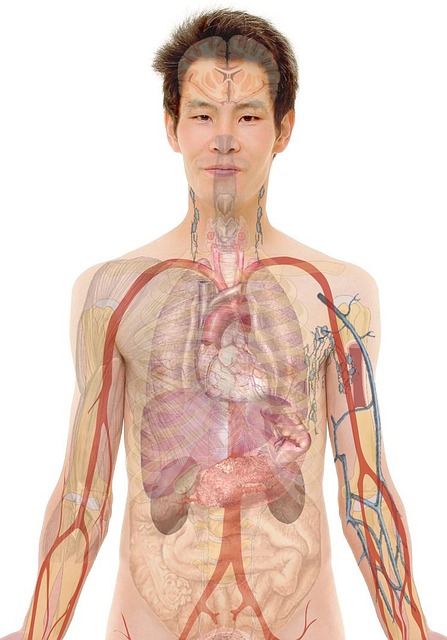

Digital measuring systems have transformed various industries by offering unparalleled precision and accuracy. In fields such as car restoration and paintless dent repair, where meticulous detail is paramount, these systems are indispensable. They utilize advanced technologies like laser scanners and 3D imaging to capture precise measurements of surfaces, ensuring that every curve, contour, and crevice is accurately mapped. This level of detail allows for more effective and efficient repairs, resulting in superior outcomes—whether it’s removing a dent or restoring a vehicle to its original gleam.

Compared to traditional measuring methods, digital systems eliminate human error and subjectivity, guaranteeing consistent and reliable data. This accuracy translates into better resource allocation, reduced waste, and faster turnaround times, making them not just tools but strategic assets for businesses in the car restoration and dent removal sectors.

– The role of technology in achieving meticulous measurements

In today’s digital era, the automotive industry has witnessed a profound transformation, largely driven by advanced technology. One area where this shift is particularly evident is in achieving meticulous measurements during auto painting and car collision repair processes. Traditional methods often relied on manual tools, which were subjective and prone to human error. However, digital measuring systems have revolutionized this landscape.

These cutting-edge technologies offer unparalleled precision, ensuring every detail is captured accurately. From 3D scanning systems that map out car bodies to specialized software that calculates paint formulations, digital measuring systems streamline car repair services, including auto painting tasks. They provide a level of consistency and efficiency never seen before, directly contributing to the quality and speed of car collision repair processes.

– Advantages over traditional methods

Digital measuring systems offer a significant leap forward compared to traditional methods in several crucial ways. One of the most notable advantages is precision and accuracy; digital tools provide detailed, exact measurements, ensuring every repair or restoration process begins with solid data. For instance, when it comes to vehicle restoration, such as a Mercedes-Benz repair, accurate measuring ensures that replacement parts fit perfectly, preserving the car’s original aesthetic.

Furthermore, these systems streamline the entire process, from initial assessment to final touch-ups. Car paint repair, for example, benefits immensely from digital measurement tools that capture surface imperfections and help technicians identify and correct them more efficiently. This not only saves time but also enhances the overall quality of work, making vehicle restoration a smoother, more precise experience.

Digital measuring systems offer a paradigm shift in precision and accuracy, revolutionizing industries that rely on meticulous data. By embracing these technologies, businesses can significantly enhance productivity, reduce errors, and gain a competitive edge. The advantages over traditional methods are undeniable, making investment in digital systems a strategic move for any forward-thinking organization.