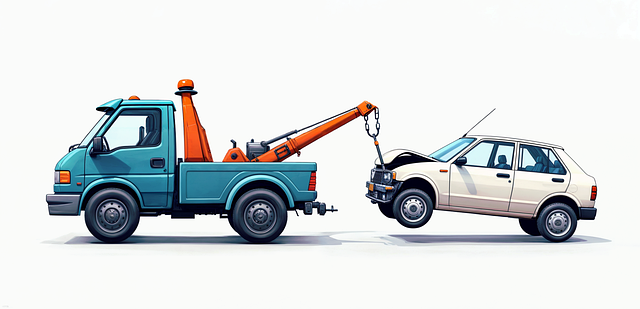

Adhering to Original Equipment Manufacturer (OEM) standards is crucial for high-quality plastic bumper repair, ensuring both aesthetic perfection and enhanced vehicle safety. Skilled technicians follow these guidelines, set by automotive manufacturers, throughout the repair process using specialized tools and materials. This precision restores critical front-end structural integrity, matches original car scratch repairs, and preserves vehicle value, making it vital for collision centers to stay current with evolving OEM standards.

Plastic bumper repairs are a complex yet vital service, especially for maintaining vehicle safety and aesthetics. Plastic Bumper Repair Technicians play a crucial role in ensuring that repairs meet Original Equipment Manufacturer (OEM) standards. This article delves into the significance of OEM standards in plastic bumper repairs, highlights the expertise required from technicians, and explores the long-term benefits—including enhanced longevity and safety—of adhering to these stringent guidelines. By understanding these aspects, car owners can make informed decisions regarding their vehicle’s repair needs.

- Understanding OEM Standards for Plastic Bumper Repairs

- The Role of Plastic Bumper Repair Technicians in Maintaining Quality

- Benefits of Adhering to OEM Standards for Longevity and Safety

Understanding OEM Standards for Plastic Bumper Repairs

When it comes to plastic bumper repair, technicians must adhere to Original Equipment Manufacturer (OEM) standards to ensure high-quality and precise restoration. OEM standards are essentially the guidelines set by vehicle manufacturers for specific parts, including bumpers. These standards cover every aspect of the repair process, from material specifications to manufacturing techniques. For example, a Mercedes Benz repair might require specific plastic composites and bonding agents approved by the manufacturer, ensuring the new bumper matches the original car scratch repair criteria perfectly.

Collision centers that offer plastic bumper repair services need to stay updated with these OEM standards as they evolve. By following these guidelines, technicians can guarantee that repairs are not only visually identical but also structurally sound, enhancing safety and preserving the vehicle’s value. This meticulous approach is crucial in maintaining the integrity of the car’s design and performance.

The Role of Plastic Bumper Repair Technicians in Maintaining Quality

Plastic bumper repair technicians play a pivotal role in maintaining the quality and integrity of vehicles at collision repair centers. They are skilled professionals who ensure that every plastic bumper repair is carried out according to Original Equipment Manufacturer (OEM) standards. These standards, set by the vehicle’s original producer, dictate precise procedures for disassembly, repair, and reassembly, guaranteeing both aesthetic perfection and structural soundness.

By adhering to OEM guidelines, these technicians deliver superior results in car collision repairs. They use specialized tools and materials designed for plastic bumper repair, meticulously restoring the bumper to its pre-accident condition. Their expertise not only preserves the vehicle’s appearance but also ensures safety by restoring the structural integrity of the front end, a critical aspect of any vehicle collision repair.

Benefits of Adhering to OEM Standards for Longevity and Safety

Adhering to Original Equipment Manufacturer (OEM) standards is paramount for plastic bumper repair technicians. These guidelines ensure that repairs are not just visually similar but also functionally equivalent to the original component, enhancing vehicle longevity and safety. By following OEM protocols, technicians can maintain the structural integrity of the bumper, ensuring it performs its critical role in protecting the vehicle’s front or rear end during collisions. This attention to detail is especially crucial for high-quality repairs like Mercedes Benz repair, where precision and authenticity are expected.

Moreover, adhering to these standards promotes consistency across all collision repair shops. Customers can expect the same level of craftsmanship regardless of which automotive repair facility they visit. For instance, a well-executed plastic bumper repair, whether at a specialized shop or a general automotive repair center, should maintain the original design and fitment, contributing to the overall reliability and safety of the vehicle.

Plastic bumper repair technicians play a vital role in ensuring vehicle longevity and safety by adhering to Original Equipment Manufacturer (OEM) standards. By following these rigorous guidelines, they maintain the quality and integrity of plastic bumper repairs, ensuring each vehicle returns to the road looking and performing as good as new. This commitment to excellence not only safeguards against future damage but also preserves the overall value of the vehicle.