Collision repair safety standards are vital guidelines designed to protect both workers and customers in auto collision centers by addressing PPE usage, ventilation, lighting, hazardous material handling, waste disposal, regular updates, and inspections. Non-compliance carries significant risks of accidents, injuries, property damage, and legal issues. Adhering to these standards is essential for maintaining a secure, efficient, and reputable auto body shop, encompassing best practices like staff training, PPE use, ventilation systems, clear communication, organized work areas, safe tools, and fostering collective responsibility among technicians.

In the fast-paced world of collision repair, adhering to safety standards is non-negotiable. This article delves into the essence of understanding and implementing collision repair safety standards, highlighting their critical role in mitigating risks and ensuring a secure work environment. By exploring the implications of non-compliance, from legal repercussions to potential injuries, we emphasize the importance of best practices. From proper training to advanced equipment utilization, discover strategies to uphold these standards, fostering a culture of safety in your repair facility.

- Understanding Collision Repair Safety Standards: The Basics

- Implications of Non-Compliance: Risks and Consequences

- Best Practices for Adhering to Safety Standards in Collision Repair

Understanding Collision Repair Safety Standards: The Basics

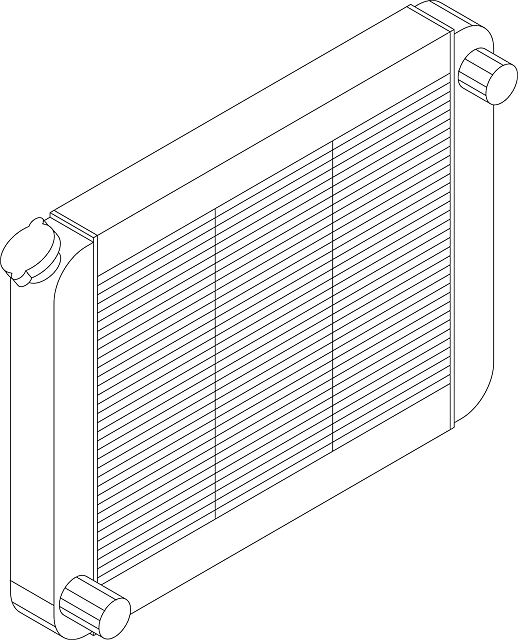

Collision repair safety standards are a set of guidelines designed to protect both workers and customers in collision centers. These standards encompass various aspects, from proper use of personal protective equipment (PPE) like gloves, eye protection, and respirators, to ensuring adequate ventilation and lighting. It also includes safe handling of hazardous materials such as paint and solvents, as well as the correct disposal of waste products.

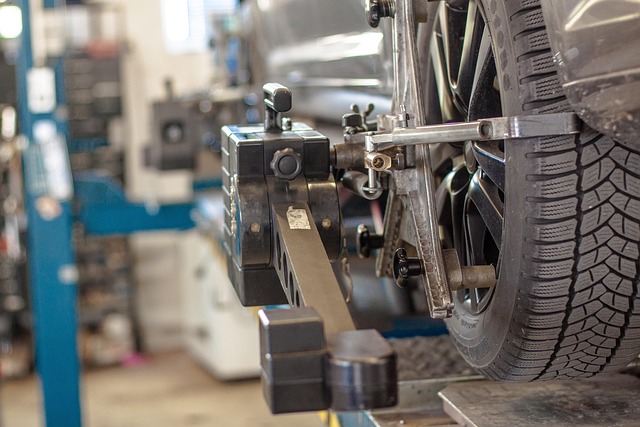

In an auto body repair or paintless dent repair process, adhering to these safety standards is crucial. For instance, technicians must be trained in the safe application of paints and sealants to avoid exposure to harmful fumes. Moreover, proper training on the use of heavy machinery and equipment is essential to prevent accidents. A well-organized collision center will regularly update its safety protocols and conduct thorough inspections to maintain a safe working environment.

Implications of Non-Compliance: Risks and Consequences

Non-compliance with established collision repair safety standards can have severe implications and significant risks for both workers and customers in a collision repair shop or auto collision center. Failure to adhere to these guidelines may result in serious accidents, injuries, or even fatalities. The consequences of neglecting safety protocols are far-reaching, impacting not only the well-being of individuals but also the reputation and financial stability of the business itself.

When collision repair procedures are skipped or mishandled, it can lead to hazardous working conditions. This might include exposure to toxic chemicals, fire hazards due to improper handling of flammable materials, or even electrocution risks. Moreover, inadequate safety measures can cause property damage, as well as legal liabilities and financial penalties for the collision repair shop or auto collision center if an incident occurs. Ensuring compliance with collision repair safety standards is not just a moral obligation but also a strategic decision to maintain a safe, efficient, and reputable operation.

Best Practices for Adhering to Safety Standards in Collision Repair

Maintaining a safe work environment is paramount in the automotive collision repair industry. Adhering to established collision repair safety standards is not merely a recommendation but an imperative for several reasons. First, it minimizes risks to workers and ensures their well-being during often complex and potentially hazardous tasks. Second, strict compliance with these standards can significantly reduce the likelihood of accidents and associated costs, including legal liabilities and damage to reputation.

Best practices for collision repair safety involve a multifaceted approach. This includes regularly training staff on safety protocols specific to various procedures, ensuring proper use and maintenance of personal protective equipment (PPE), implementing robust ventilation systems to control fumes and debris, and establishing clear communication channels during repairs. Moreover, keeping work areas organized, utilizing appropriate tools designed for safety, and fostering a culture where safety is the collective responsibility of every technician contribute to an overall safer collision repair environment. By consistently adopting these practices, automotive collision repair businesses can protect their employees, enhance operational efficiency, and maintain high-quality collision repair services.

Collision repair safety standards are non-negotiable due to the inherent risks involved in automotive collision restoration. Non-compliance carries severe implications, from legal repercussions to potential harm to technicians and future vehicle integrity. Implementing best practices ensures a secure working environment, enhances service quality, and safeguards against unforeseen dangers. By adhering to these standards, collision repair facilities can mitigate risks, maintain operational efficiency, and foster trust among their clientele.