Pickup truck body repair has evolved significantly due to advancements in auto technology and changing consumer demands. Traditional metalworking methods have been replaced by sophisticated techniques using CAD software, robotic welding systems, vacuum degassing, and composite materials for improved strength, stability, fuel efficiency, and durability. This shift reflects an industry trend towards efficient, precise, and eco-friendly practices. The growing popularity of pickup trucks has led to specialized repair facilities with advanced tools and trained professionals, offering quicker and cost-effective repairs while maintaining superior craftsmanship. Future developments in automation, robotics, 3D printing, digital design software, and CAM systems promise even more accessible, efficient, and sustainable pickup truck body repair services.

“Pickup truck body repair has evolved dramatically, transforming auto service industries and setting new standards. This article delves into the fascinating journey of repair techniques, from traditional methods to modern advancements. We explore how these changes have led to increased efficiency and specialization in auto care.

Additionally, we peek into the future, uncovering emerging technologies that promise even more innovative pickup truck body repairs. Get ready to discover how these trends are redefining the landscape of vehicle restoration.”

- The Evolution of Pickup Truck Body Repair Techniques

- Impact on Auto Service Industries: Efficiency and Specialization

- Future Trends: Advanced Technologies in Truck Body Repairs

The Evolution of Pickup Truck Body Repair Techniques

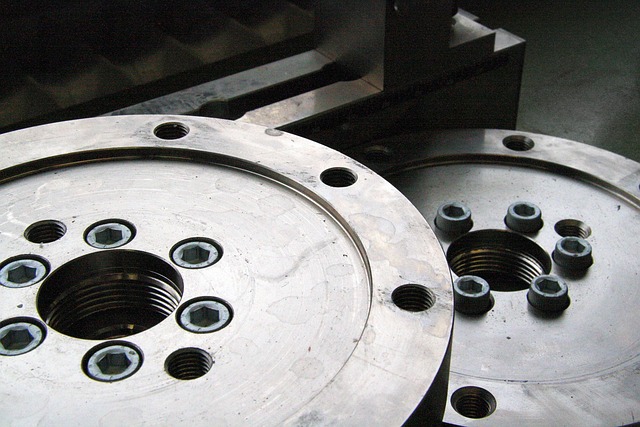

The evolution of pickup truck body repair has been a significant transformation, mirroring the advancements in auto technology and customer expectations. Historically, repairs involved traditional metalworking methods, where skilled technicians meticulously welded and hammered damaged panels back into shape. However, with the introduction of modern materials and techniques, pickup truck body repair has become increasingly sophisticated. Advanced technologies like computer-aided design (CAD) software enable precise measurements and accurate panel replacement, ensuring vehicles return to their original factory specifications.

This shift towards precision repair is not just about maintaining aesthetics; it also ensures structural integrity. Modern auto repair shops now employ advanced tools such as robotic welding systems and vacuum degassing for improved strength and stability. Moreover, the integration of composite materials has further revolutionized pickup truck body repair, offering lightweight alternatives to traditional steel, thereby enhancing fuel efficiency without compromising durability. These advancements reflect a broader trend in the automotive industry, moving away from conventional car body restoration methods towards more efficient, precise, and eco-friendly practices.

Impact on Auto Service Industries: Efficiency and Specialization

The rise of pickup truck body repair has significantly reshaped the auto service industries, fostering a new era of efficiency and specialization. With the increasing popularity of trucks, there’s been a corresponding demand for specialized services tailored to their unique construction and needs. This shift has led to the development of dedicated repair facilities equipped with advanced tools and training in truck bodywork, including frame straightening, panel replacement, and auto painting to match original factory finishes.

This specialization allows for quicker turnaround times and higher-quality repairs compared to general auto repair shops. Auto dent repair, for instance, has evolved to include sophisticated techniques like PDR (Paintless Dent Repair) that preserve the original car bodywork and paint, saving time and costs. This focus on efficiency and precision benefits both customers and businesses, ensuring that their trucks are back on the road safely and reliably in less time than ever before.

Future Trends: Advanced Technologies in Truck Body Repairs

The future of pickup truck body repair is poised for a significant transformation with the integration of advanced technologies. Automation and robotics are expected to play a pivotal role, allowing for precise and efficient repairs, reducing manual labor-intensive tasks. 3D printing technology, for instance, could revolutionize the industry by offering rapid prototyping and custom parts fabrication, enabling faster and more accurate replacements for damaged or worn-out components.

Furthermore, digital design software and computer-aided manufacturing (CAM) systems will streamline the repair process, enhancing precision and consistency. These technologies enable body shops to provide state-of-the-art vehicle dent repair and intricate panel replacement services with minimal waste and enhanced quality. As these innovations mature, pickup truck body repair services are set to become more accessible, affordable, and environmentally sustainable.

Pickup truck body repair has undergone a remarkable evolution, transforming auto service industries with enhanced efficiency and specialized techniques. As we look towards the future, advanced technologies promise even faster and more precise repairs, further revolutionizing the landscape of vehicle maintenance. This continuous adaptation ensures that pickup truck owners receive top-notch services tailored to their unique needs, setting new standards in the industry.