TL;DR: To perform effective plasma cutting collision repairs, prepare a spacious, well-lit workspace with protected flooring. Securely set up equipment, organize tools and materials, and position workpieces securely. Prioritize safety through ventilation, proper PPE, and a clear, organized space to mitigate risks from sparks, fumes, and debris, ensuring high-quality auto repair outcomes.

Plasma cutting has emerged as a game-changer in collision repair, offering precise and efficient metal fabrication. This advanced technique enables professionals to navigate complex repairs with ease. From preparing your workspace for optimal safety and ventilation to mastering cut settings for diverse materials, this guide provides essential tips for achieving top-notch plasma cutting collision repair results. Discover how to leverage plasma cutting for panel replacements, weld repairs, and structural enhancements, ensuring seamless integration and restored aesthetics.

- Preparing Your Workspace for Plasma Cutting Collision Repair

- – Choosing the right location and setting up a safe, organized workspace

- – Ensuring proper ventilation and safety measures

Preparing Your Workspace for Plasma Cutting Collision Repair

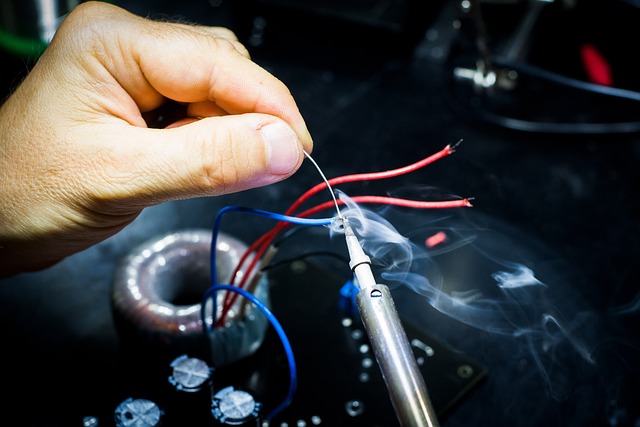

Before tackling any plasma cutting collision repair, ensuring your workspace is prepared and optimized is key. Start by clearing a dedicated area where you can set up your equipment safely. This zone should be well-lit, with ample space for movement and manipulation of parts. Protecting the floor with drop cloths or mats is essential to prevent damage from sparks and debris. Additionally, setting up your plasma cutter, ensuring all connections are secure, and having a supply of replacement parts like plasma cutting electrodes handy will streamline the process.

Consider the layout and organization of tools and materials for seamless workflow. For instance, position your workpiece securely on a sturdy table or stand, aligning it with the plasma cutter’s path. Keep commonly used accessories within easy reach to avoid unnecessary delays. Remember, a prepared workspace enhances precision, efficiency, and safety during plasma cutting collision repair, ensuring better outcomes for tasks like bumper repair, vehicle dent repair, or auto glass repair.

– Choosing the right location and setting up a safe, organized workspace

When engaging in plasma cutting collision repair, setting up a dedicated workspace is paramount for both efficiency and safety. The ideal location should be spacious enough to accommodate the necessary equipment and allow for ample movement around the workpiece. Moreover, ensuring proper ventilation is crucial due to the potential for harmful fumes and debris. A well-organized space with designated areas for tools, materials, and waste management streamlines the repair process. This organization not only saves time but also reduces the risk of accidents or misplacing essential components, especially when dealing with intricate car repair services or auto painting projects.

Considerations for workspace setup include choosing a flat, stable surface to support heavy machinery and workpieces. Proper lighting is another critical aspect to ensure clear visibility during the repair process. Additionally, incorporating safety features like fire extinguishers and protective gear storage nearby can significantly enhance the overall safety of the workspace. With these factors in mind, you’ll be well-prepared to tackle plasma cutting collision repair tasks with confidence, leveraging your organized space for efficient auto repair services and high-quality car repair outcomes.

– Ensuring proper ventilation and safety measures

When employing plasma cutting techniques for collision repair, prioritizing safety is paramount. This involves setting up a well-ventilated area to mitigate the risk of inhaling harmful fumes and sparks. Adequate ventilation ensures that any toxic gases or particulate matter generated during the cutting process are effectively dispersed, creating a safer working environment for both technicians and bystanders in nearby areas.

In an auto repair shop or collision repair shop, implementing robust safety protocols is crucial. This includes donning appropriate personal protective equipment (PPE), such as safety goggles, welding masks, and fire-resistant clothing, to safeguard against potential hazards. Additionally, ensuring a clear and organized workspace helps prevent accidental collisions and facilitates efficient collision repair procedures, ultimately contributing to the overall quality of the car bodywork.

Plasma cutting collision repair is a precise and efficient method for automotive body work, requiring a well-prepared workspace and adherence to safety protocols. By choosing the right location, setting up proper ventilation, and implementing organized storage, you create an environment conducive to accurate, clean cuts. Remember, safety should always be your top priority when employing plasma cutting techniques, ensuring a smooth and successful repair process.