Tesla's adoption of structural aluminum offers enhanced safety and performance due to its superior strength-to-weight ratio, ideal for reducing vehicle weight without compromising integrity. After minor accidents, specialized and meticulous repair techniques are required to preserve the vehicle's original shape, with corrosion resistance making it suitable for maintaining the exterior's pristine condition. Proper post-accident care includes early assessment, genuine Tesla parts, professional painting services, and regular maintenance to ensure the longevity of structural aluminum repairs.

“Tesla vehicles, renowned for their innovative design and advanced materials, incorporate structural aluminum for enhanced durability. However, minor accidents can impact these lightweight structures. This article delves into the world of Tesla structural aluminum repair, offering a comprehensive guide to understanding this unique material, its repair process, and essential post-accident care tips. Learn how to maximize the longevity of your Tesla’s repairs and ensure its continued performance.”

- Understanding Tesla Structural Aluminum: Material Properties and Why It Matters After Accidents

- The Process of Structural Aluminum Repair for Tesla Vehicles: Step-by-Step Guide

- Tips for Effective Post-Accident Care: Maximizing the Longevity of Your Tesla's Structural Aluminum Repairs

Understanding Tesla Structural Aluminum: Material Properties and Why It Matters After Accidents

Tesla’s use of structural aluminum in their vehicles is a game-changer in the automotive industry, offering a unique blend of strength and lightweight properties. This material is not just aesthetically appealing; it plays a crucial role in vehicle safety and performance. Structural aluminum is renowned for its superior strength-to-weight ratio, making it an ideal choice for modern car designs aiming to reduce overall vehicle weight without compromising structural integrity. After minor accidents, understanding these material properties becomes essential for effective Tesla structural aluminum repair.

When a Tesla, or any vehicle for that matter, experiences an impact during an accident, the structural integrity of its bodywork is paramount. Aluminum’s ability to withstand force while maintaining dimensional accuracy means that even after a fender bender, repairs can be more straightforward and less expensive compared to steel bodies. This is especially beneficial in auto collision repair, as it preserves the vehicle’s original shape and structure, ensuring optimal safety and performance post-repair. The material’s corrosion resistance also makes it a preferred choice for auto detailing, keeping the vehicle’s exterior looking pristine even after minor scuffs or dings.

The Process of Structural Aluminum Repair for Tesla Vehicles: Step-by-Step Guide

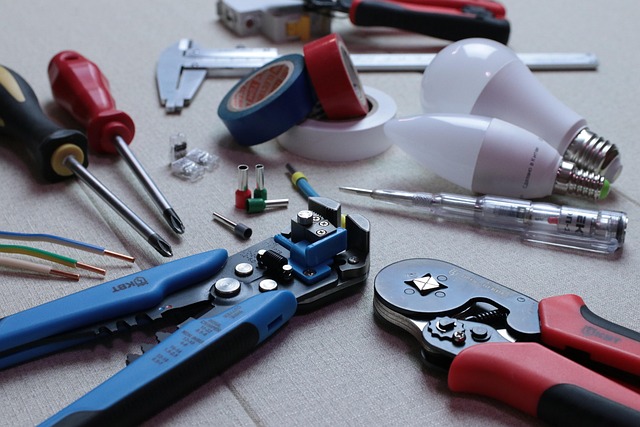

The process of Tesla structural aluminum repair after minor accidents involves a meticulous and specialized approach to ensure the vehicle’s safety and aesthetics remain intact. It begins with a thorough inspection, where technicians assess the damage, identifying dents, creases, or deformations in the aluminum body panels. Using advanced tools, they measure and mark the affected areas precisely, preparing for accurate repairs.

The repair process is a multi-stepped procedure. First, the damaged panel is carefully removed, allowing access to the underlying structure. Next, any bent or misaligned components are straightened using specialized equipment. After that, technicians fill and smoothen out dents, ensuring a seamless surface. The panel is then cleaned, primed, and painted with high-quality auto paint to match the vehicle’s original finish, seamlessly integrating it back into the Tesla’s overall design and protective coating.

Tips for Effective Post-Accident Care: Maximizing the Longevity of Your Tesla's Structural Aluminum Repairs

After a minor accident, proper post-accident care is essential to ensure your Tesla’s structural aluminum repairs last. Start by assessing any damage immediately; visual inspections can help identify even subtle dents or deformations. Early intervention is key to preventing further issues. Next, take your vehicle to a reputable automotive body shop specializing in Tesla structural aluminum repair. These experts have the tools and knowledge to address complex panel geometry and unique material properties.

During the repair process, ensure all components are replaced with genuine Tesla parts to maintain structural integrity and original factory finishes. Consider auto body painting services if repairs include panel replacement or significant dents. Skilled technicians will match the color precisely, ensuring a seamless finish that enhances your Tesla’s overall aesthetics. Regular maintenance after repairs, including washing and waxing, can also protect the repair work, extending its longevity.

In conclusion, understanding and properly repairing Tesla’s structural aluminum after minor accidents is key to preserving the vehicle’s integrity and longevity. By familiarizing yourself with the unique properties of this advanced material and following a meticulous repair process, you can ensure your Tesla maintains its structural strength and aesthetic appeal. With the right care and attention, Tesla owners can extend the life of their vehicles, enjoying many more miles on the road with confidence.