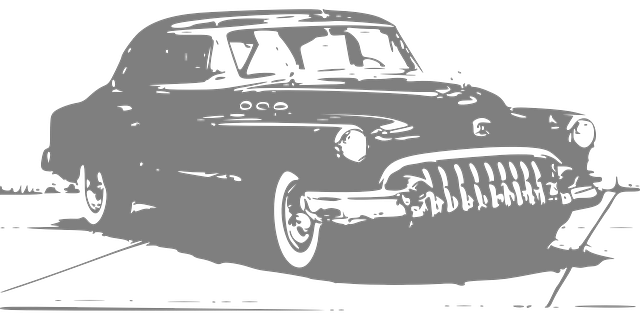

Block sanding techniques are crucial for flawless vehicle bodywork, especially in hybrid and electric cars with intricate designs. This method uses a block sander to evenly remove dents, scratches, and imperfections without leaving marks. For professionals, it's a game-changer, enabling precise repairs that go unnoticed. Effective block sanding requires proper tools: high-quality sandpaper, versatile sanders, masking tape, adhesive, and specialized blocks. The process involves selecting the right grit, securing the sandblock, applying even strokes, inspecting for evenness, and wiping down post-sanding.

In the realm of automotive refinishing, block sanding techniques have emerged as a game-changer for hybrid and electric vehicles. This innovative method offers precise control and efficient surface preparation, crucial for achieving flawless finishes on complex vehicle bodies. Understanding block sanding’s intricacies and utilizing the right tools are essential steps towards mastering this process. Discover optimal techniques to ensure smooth finishes, enhancing the overall quality of your automotive repair and customization projects.

- Understanding Block Sanding for Automotive Applications

- Essential Tools and Materials for Efficient Block Sanding

- Step-by-Step Guide to Achieving Smooth Finishes with Block Sanding Techniques

Understanding Block Sanding for Automotive Applications

Block sanding techniques play a pivotal role in achieving flawless vehicle bodywork, especially for hybrid and electric vehicles known for their intricate designs and precision manufacturing. This method involves using a block sander, a versatile tool designed to sand and shape various materials, including auto collision centers’ workpieces like fenders, doors, and bonnets. The key advantage lies in its ability to apply consistent pressure across the surface, ensuring even sanding without leaving scratches or creating uneven surfaces.

For auto dent repair professionals, block sanding is a game-changer when it comes to restoring vehicle aesthetics. It allows for precise removal of dents, scratches, and imperfections from the vehicle’s bodywork, contributing to a seamless finish. By skillfully utilizing block sanding techniques, experts can transform damaged vehicle exteriors into striking, almost unnoticeable repairs, showcasing their craftsmanship in auto dent repair.

Essential Tools and Materials for Efficient Block Sanding

Efficient block sanding requires a well-equipped toolkit tailored for precision and effectiveness. The foundation lies in high-quality sandpaper with various grits, from coarse to fine, to achieve smooth finishes. A versatile sander, whether electric or pneumatic, is essential for reaching tight spots and controlling the sanding process. For hybrid and electric vehicle repairs, where meticulous work is crucial, a digital readout sander can ensure consistent speed control, enabling precise results.

Complementing these tools are essential materials like masking tape, sandpaper adhesive, and various blocks designed for specific surfaces. In car collision repair or car body restoration projects, these tools facilitate the transformation of damaged panels into flawless finishes. The right combination of techniques and materials ensures that block sanding not only repairs but also enhances the overall quality of the vehicle’s exterior, meeting the highest standards in car body repair.

Step-by-Step Guide to Achieving Smooth Finishes with Block Sanding Techniques

Achieving a smooth, impeccable finish on hybrid or electric vehicle bodies is an art, and block sanding techniques are the precision tools needed for this task. This method involves using a sandblock (a padded block with abrasive paper) to even out surfaces, remove minor imperfections, and prepare the paint job. Begin by selecting the appropriate grit level of sandpaper based on the desired finish; coarser papers for heavy-duty work and finer grades for delicate touchups. Next, secure the sandblock firmly in your hand or a sanding tool, ensuring control during application.

Move the block in smooth, even strokes, applying consistent pressure across the panel. Start with larger motions to cover significant areas, then transition to smaller, more targeted movements around curves and corners. Regularly inspect the work area, lifting the sandblock occasionally to assess progress and ensure an even finish. For hard-to-reach spots or minor scratches, a handheld block allows for precise manipulation. After sanding, thoroughly wipe down the surface to remove dust, ensuring a clean canvas for the next stage of auto repair services or the final auto detailing touch.

Block sanding techniques are revolutionizing the automotive industry, particularly for hybrid and electric vehicles. By understanding the process, selecting the right tools and materials, and following a step-by-step guide, professionals can achieve smooth finishes that enhance vehicle aesthetics and performance. These techniques offer an efficient, precise method for preparing surfaces, ensuring top-notch results in today’s demanding automotive market.