Auto body moldings are essential for vehicles' visual appeal and protection, sealing gaps, preventing corrosion, and protecting against damage. Traditionally time-consuming and costly to create, advancements in technology have led to versatile moldings that adapt to various car models using CAD and precision engineering. This innovation allows for seamless, factory-like finishes during repairs, enhancing vehicle aesthetics and streamlining work for collision centers, ultimately benefiting customers with superior results.

“Revolutionize your vehicle’s aesthetic with auto body moldings—essential accessories that enhance both style and functionality. These moldings play a vital role in protecting your car’s body while adding a touch of customization. However, achieving a perfect fit across various vehicle models has long been a challenge. In this article, we explore how precision engineering has transformed the game, making it possible to create auto body moldings that fit precisely, no matter the make or model.”

- Understanding Auto Body Moldings: Their Role and Benefits

- The Challenge of Universal Fit: Overcoming Design Differences Across Models

- How Precision Engineering Makes Custom-Like Fit Possible for All Vehicles

Understanding Auto Body Moldings: Their Role and Benefits

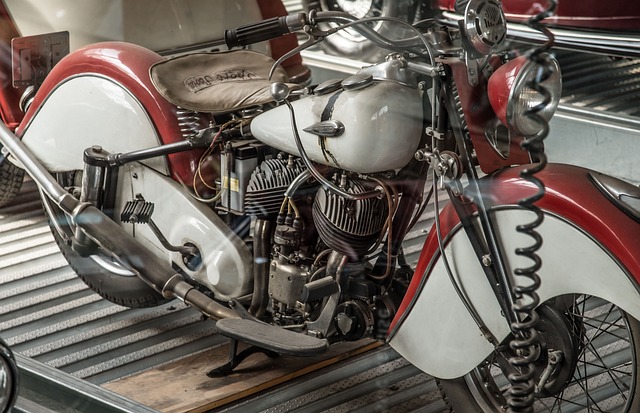

Auto body moldings play a crucial role in both the aesthetic and functional aspects of vehicle maintenance. These intricate pieces are designed to fit precisely around a car’s body, enhancing its overall look while providing protection against damage. Moldings can be found on various parts of a vehicle, from door panels to fenders and even on the hood or trunk lid. Their primary function is to seal gaps between different body components, preventing water intrusion and corrosion. This is especially vital for exterior paint jobs, as moldings help maintain the integrity of auto painting by keeping out moisture that could lead to peeling or blistering.

Beyond aesthetics, auto body moldings offer practical benefits, particularly in vehicle dent repair. They serve as a protective barrier against minor dents, scrapes, and bumps encountered during everyday driving. For instance, a well-fitted fender molding can prevent damage when passing through car washes or navigating tight spaces. Even more specialized molds can be found on luxury vehicles like Mercedes Benz repair parts, ensuring not just precision fitting but also contributing to the vehicle’s unique design appeal.

The Challenge of Universal Fit: Overcoming Design Differences Across Models

Creating auto body moldings that fit precisely on all vehicle models presents a unique challenge. Each car and truck model has distinct design differences, from contour variations to specific panel shapes and sizes. These variances make it difficult for universal molding solutions to accommodate every curve and edge perfectly. Traditional methods often require custom fabrication for each vehicle, which increases both time and cost.

However, advancements in technology and manufacturing processes have enabled the development of versatile auto body moldings. By leveraging sophisticated design software and precision engineering, manufacturers can now create adaptable components that work harmoniously with diverse model aesthetics. This evolution ensures that drivers can enjoy seamless, factory-like finishes, even when opting for aftermarket repairs or enhancements, such as car scratch repair, fender repair, or car paint services.

How Precision Engineering Makes Custom-Like Fit Possible for All Vehicles

Precision engineering plays a pivotal role in achieving a custom-like fit for auto body moldings across various vehicle models. By employing advanced manufacturing techniques and intricate design processes, engineers are able to create moldings that perfectly align with the unique contours and specifications of each car make and model. This level of precision ensures that every molding not only looks factory-fitted but also functions optimally, enhancing the overall aesthetics and structural integrity of the vehicle.

Such engineering prowess involves meticulous measurements, computer-aided design (CAD), and advanced machining processes. These methods allow for the creation of intricate moldings that can accommodate the subtle differences in body panels between models, ensuring a seamless fit even in complex areas like fenders, bumpers, and door sills. This is particularly beneficial for collision repair centers and car scratch repair specialists, as it streamlines their work, reduces labor costs, and expedites vehicle paint repair processes, ultimately providing customers with superior results.

Auto body moldings, once a realm of custom-fit complexity, are now accessible to all vehicle owners thanks to precision engineering. By overcoming the challenges of varying design differences across models, these moldings offer both aesthetic enhancement and practical protection. In today’s automotive landscape, high-quality auto body moldings that fit precisely are not just a possibility—they’re a game-changer, ensuring every vehicle looks as sleek and unified as possible, regardless of its make or model.