Spectrophotometer color matching is a precise scientific process using advanced optics and photometrics to analyze light intensity at specific wavelengths, ensuring accurate hue, saturation, and brightness analysis. In automotive repair, these tools are invaluable for restoring vehicles to their original aesthetic condition, enhancing visual appeal, maintaining vehicle value, and revolutionizing traditional methods with consistent, chemical-level matching. This technology is transforming quality control across industries, from automotive paints to car restoration and manufacturing, by accurately measuring light absorption for exact color reproduction, optimizing processes, reducing waste, and enhancing product quality.

“Unleash the power of precise color control with Spectrophotometer Color Matching (SPCM). This advanced technology is transforming industries by offering an unprecedented level of accuracy in color measurement. From manufacturing and textiles to cosmetics and art, SPCM ensures consistent and exact colors. By understanding the science behind it—analyzing light absorption at specific wavelengths—it becomes a game-changer for quality control and innovation. Embrace this technology to elevate your product standards and unlock new creative possibilities.”

- Understanding Spectrophotometer Color Matching: The Science Behind It

- Benefits of Adopting Spectrophotometer Color Matching Technology

- Implementing and Optimizing Spectrophotometer Color Matching in Various Industries

Understanding Spectrophotometer Color Matching: The Science Behind It

Spectrophotometer color matching is a precise scientific process that assesses and compares colors with remarkable accuracy. It works by measuring the intensity of light at specific wavelengths, allowing for detailed analysis of hue, saturation, and brightness. This technology emulates the human eye’s perception, ensuring incredibly reliable results. The science behind it involves advanced optics and photometrics, capturing and interpreting color data with meticulous care.

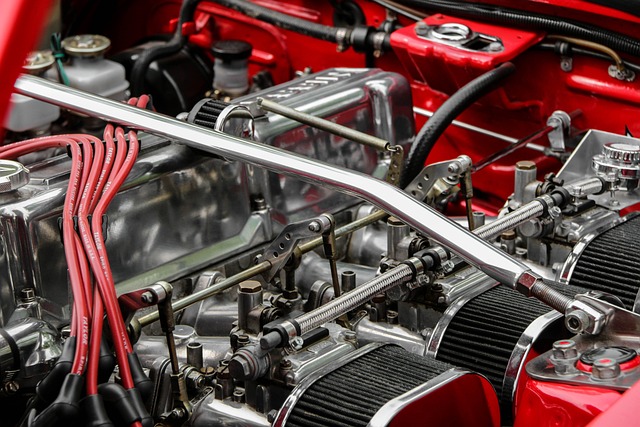

In the context of car damage repair or automotive repair, this method is invaluable for auto body shops aiming to restore vehicles to their original aesthetic condition. By using a spectrophotometer, professionals can match colors precisely, ensuring that repairs blend seamlessly with the vehicle’s existing finish. This attention to detail not only enhances the visual appeal but also maintains the car’s overall value and longevity.

Benefits of Adopting Spectrophotometer Color Matching Technology

Adopting spectrophotometer color matching technology offers significant advantages for various industries, particularly those involved in vehicle repair services and fender repair. This innovative tool revolutionizes traditional color matching methods by providing precise and consistent results. With its advanced capabilities, it ensures that every repair job matches not just visually but also in terms of chemical composition, creating a seamless blend with the original car body.

This technology is instrumental in enhancing the quality of repairs, especially in complex cases where matching the exact shade can be challenging. By analyzing light absorption and reflection at specific wavelengths, spectrophotometers deliver accurate color measurements, eliminating subjective human assessment. This precision translates to better customer satisfaction and a more professional finish, making it an indispensable asset for any automotive body repair shop or paint manufacturing company aiming to excel in their fender repair services.

Implementing and Optimizing Spectrophotometer Color Matching in Various Industries

Implementing spectrophotometer color matching across various industries is revolutionizing quality control and precision. This advanced technology, which measures light absorption at specific wavelengths, ensures exact color reproduction in a multitude of applications. From vibrant automotive paints to intricate car restoration projects, the benefits are clear. It enables professionals to achieve seamless matches, preserving aesthetic appeal and ensuring customer satisfaction.

In vehicle collision repair, for instance, spectrophotometry is instrumental in accurately matching colors on damaged cars, ensuring repairs that blend seamlessly with the original finish. The same precision applies to other sectors like manufacturing, where consistent color across products is paramount. By leveraging this technology, businesses can optimize their processes, reduce waste, and elevate their product quality, be it in the production of textiles, coatings, or even electronic components.

Spectrophotometer color matching offers a precise and efficient solution for color control, making it an invaluable asset across various industries. By understanding the science behind this technology and its numerous benefits, businesses can optimize their processes and ensure consistent, high-quality results. From manufacturing to cosmetics, adopting spectrophotometer color matching technology is a game-changer that enhances productivity, reduces waste, and ultimately improves customer satisfaction.