PDR (Paintless Dent Repair) for aluminum panels is a revolutionary, eco-friendly method in the automotive industry, offering specialized tools and techniques to restore minor damage to modern aluminum car bodies. Preferred by both professionals and DIYers, it preserves the original finish, cuts costs, and boosts efficiency compared to traditional painting methods. Implementing PDR requires investment in high-quality tools, trained technicians, and structured processes including regular inspections and clear communication standards for consistent, high-quality repairs.

“Unleash the potential of PDR (Punt, Drag, and Roll) techniques for repairing aluminum panels with our comprehensive guide. This article offers a detailed exploration of PDR, a game-changing approach in the automotive repair industry. We delve into its advantages, from cost-effectiveness to enhanced panel strength. Learn practical steps to master PDR skills, optimize repair processes, and transform your aluminum panel restoration capabilities. Discover why adopting PDR is a smart move for efficient, high-quality repairs.”

- Understanding PDR for Aluminum Panels: A Comprehensive Overview

- The Benefits of Adopting PDR for Aluminum Panel Repairs

- Practical Steps to Implement and Optimize PDR Techniques for Aluminum Panels

Understanding PDR for Aluminum Panels: A Comprehensive Overview

PDR for aluminum panels is a specialized process that has gained significant attention in the automotive industry. It stands for Paintless Dent Repair, a technique that offers an innovative solution for repairing minor dents and scratches on aluminum car bodywork. This method is particularly advantageous as it preserves the original finish of the vehicle, ensuring a seamless repair that is often unnoticeable to the naked eye.

Aluminum panels, commonly used in modern car construction due to their lightweight and corrosion-resistant properties, require a delicate approach when damaged. PDR for aluminum involves using specialized tools and techniques to gently work out dents without compromising the integrity of the metal or disturbing its protective coating. This non-invasive method is not only cost-effective but also swift, making it a preferred choice for both professional car bodywork services and DIY auto repair enthusiasts alike.

The Benefits of Adopting PDR for Aluminum Panel Repairs

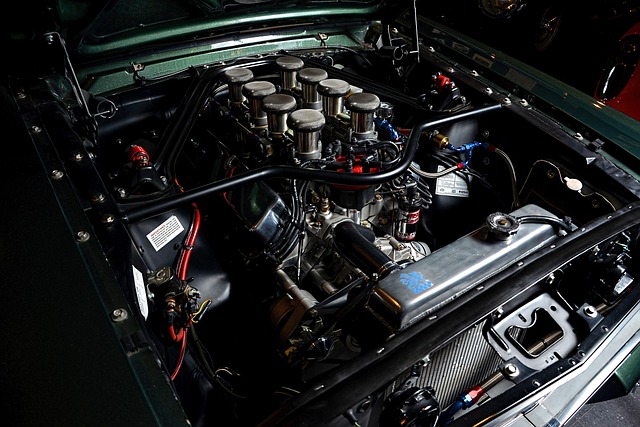

Adopting PDR (Paintless Dent Repair) for aluminum panel repairs offers numerous benefits for both vehicle owners and auto body shops. One of the most significant advantages is its ability to restore damaged panels to their original condition without the need for traditional car paint services. This non-invasive technique preserves the integrity of the metal, ensuring that the structural strength and corrosion resistance of aluminum panels are maintained.

Moreover, PDR is an eco-friendly solution as it significantly reduces waste generated during auto body work. By minimizing the use of new paints and materials, this innovative process contributes to a more sustainable approach to vehicle maintenance. For auto body shops, incorporating PDR into their service offerings can lead to increased efficiency and cost savings, while providing customers with faster turnaround times and high-quality repairs that match the original factory finish.

Practical Steps to Implement and Optimize PDR Techniques for Aluminum Panels

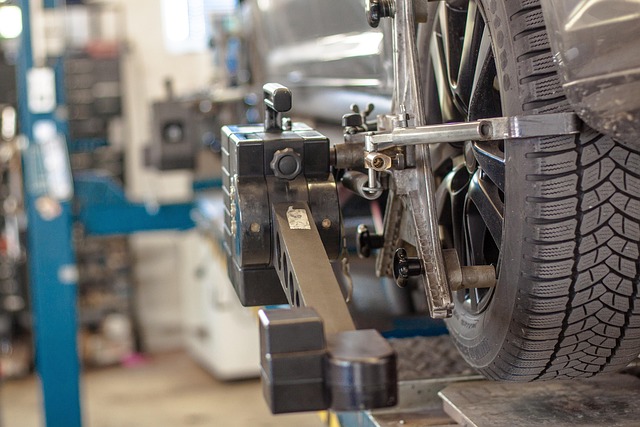

Implementing and optimizing PDR (Paintless Dent Repair) techniques for aluminum panels requires a structured approach to ensure optimal results. Start by investing in high-quality tools designed specifically for aluminum, as they offer the precision needed to navigate the panel’s unique characteristics. Trained technicians are paramount; consider comprehensive training programs that focus on both theory and hands-on experience with aluminum PDR.

Regularly inspect panels before and after treatment to understand the extent of damage and visualize successful outcomes. Adapt techniques based on panel thickness, alloy composition, and dent size. Incorporate advanced tools like air guns and specialized dents pulling tools for efficient and precise repairs. Remember, effective communication between technicians and clear understanding of standards are key to consistent quality in auto painting and collision repair processes involving PDR for aluminum panels.

As we’ve explored, adopting PDR (Punture, Dent Removal) techniques for aluminum panel repairs offers numerous benefits, from enhanced aesthetics to cost-effectiveness and faster turnaround times. By understanding the process and implementing best practices outlined in this guide, you’re well-equipped to take the next steps in incorporating PDR for aluminum panels into your workflow. Remember that continuous learning and optimization are key; staying updated with advancements in PDR techniques will ensure you provide top-quality repairs that meet the evolving demands of the industry.