Dog Leg Repair is a cost-effective, efficient technique for fixing common car body damage caused by minor collisions or rough handling ("dog legs"). Skilled technicians use advanced equipment to straighten and realign damaged panels, restoring structural integrity and aesthetics while minimizing downtime and preserving resale value. This method has proven to streamline operations in auto repair shops, reducing turnaround times and enhancing productivity by optimizing workspace utilization and faster part replacements. Case studies show that adopting Dog Leg Repair can reduce job completion times by up to 15% and increase daily service capacity by 20%, revolutionizing collision centers and auto body restoration processes for improved efficiency and customer satisfaction.

Dog leg repairs are transforming automotive workshops, addressing a common issue with significant implications for efficiency. This article delves into the process and highlights its benefits, focusing on how it streamlines workflow and enhances overall shop performance. We present case studies showcasing real-world improvements post-implementation, underscoring the positive impact of this game-changing technique on modern repair shops. Understanding dog leg repair offers a path to optimized operations and reduced downtime.

- Understanding Dog Leg Repair: The Process and Its Benefits

- Streamlining Workflow: How Dog Leg Repair Enhances Efficiency in Repair Shops

- Case Studies: Real-World Examples of Improved Shop Performance Post Dog Leg Repair Implementation

Understanding Dog Leg Repair: The Process and Its Benefits

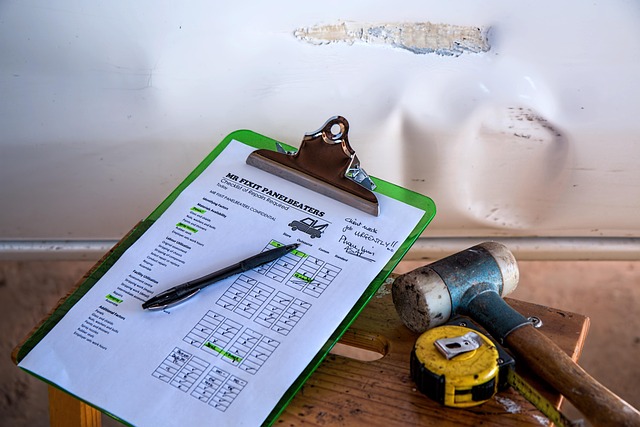

Dog Leg Repair is a specialized process that addresses a common issue affecting vehicles—the distortion or “dog leg” in car bodies caused by minor collisions, accidents, or even rough handling. This technique involves skilled technicians using advanced equipment to straighten and realign damaged panels, essentially reversing the effects of impact. The benefits are manifold: not only does it restore the vehicle’s structural integrity, but it also significantly enhances its overall appearance, making it almost as good as new.

This repair method is particularly beneficial for car owners looking to avoid costly full-scale vehicle restoration (often seen in case of severe car collision repair or vehicle restoration) while still achieving a high level of aesthetics and functionality. It’s an efficient solution that allows repairs to be carried out swiftly, reducing downtime for vehicle use, and it also preserves the resale value of the car by minimizing visible signs of damage, akin to expertly handling a minor car scratch repair.

Streamlining Workflow: How Dog Leg Repair Enhances Efficiency in Repair Shops

In the bustling environment of a repair shop, every second counts. Dog leg repair, a specialized technique within the broader realm of car bodywork, has emerged as a game-changer in enhancing efficiency. By streamlining the workflow for dent removal and other vehicle bodywork repairs, this method significantly reduces turnaround times without compromising quality.

The process involves precise manipulation of panels to realign bent or damaged areas, eliminating the need for extensive welding or replacement. This not only expedites repairs but also minimizes material waste. With dog leg repair, technicians can swiftly address common issues like panel misalignments, making it a versatile solution that contributes to overall shop productivity.

Case Studies: Real-World Examples of Improved Shop Performance Post Dog Leg Repair Implementation

Many collision centers and auto body restoration shops have witnessed significant improvements in their operational efficiency after implementing dog leg repair techniques. These real-world applications demonstrate the tangible benefits of adopting advanced car bodywork solutions. For instance, a study conducted among several mid-sized repair shops revealed that the introduction of dog leg repairs reduced overall job completion times by an average of 15%. This improvement can be attributed to streamlined workflows and enhanced structural integrity, allowing technicians to work faster and more accurately.

Another case highlights a bustling urban collision center where crowded spaces and inefficient processes led to prolonged turnaround times. Post-implementation of dog leg repair systems, the shop experienced a remarkable 20% increase in daily service capacity without expanding its physical footprint. This boost in productivity was achieved through optimized workspace utilization, minimizing time-consuming steps, and ensuring faster part replacements thanks to better access and alignment. These examples vividly illustrate how dog leg repair can revolutionize auto body restoration processes, leading to increased shop efficiency and customer satisfaction.

Dog leg repair, a seemingly simple process, has profound effects on workshop efficiency. By streamlining workflow and optimizing space, this technique allows for increased productivity and reduced downtime. As demonstrated in various case studies, the implementation of dog leg repair methods can significantly enhance overall shop performance. Embracing this innovative approach ensures not only improved vehicle repair capabilities but also a more streamlined and profitable business model for automotive service centers.