Advancements in automotive technology, particularly the widespread adoption of high-strength steel, have transformed auto body shop operations, especially in frame repair. Recent updates to frame repair safety standards emphasize structural integrity and worker protection during repairs on modern vehicles with sophisticated safety systems. These changes involve advanced welding techniques, specialized tools, and staff training in enhanced safety measures, ensuring efficient, non-compromising, and safe repairs while maintaining comparable performance and safety ratings to new models.

The automotive industry’s shift towards high-strength steel (HSS) in vehicle construction presents both advantages and challenges, particularly in frame repair. Recognizing this evolving landscape, recent updates to frame repair safety standards are crucial for ensuring worker protection during HSS frame repairs. This article delves into the necessity of these updates, highlights key changes in repair techniques, and emphasizes the importance of implementing new protocols for enhanced safety in the face of advanced steel technologies.

- Understanding the Need for Updated Safety Standards

- Key Changes and Improvements in High-Strength Steel Frame Repair

- Implementing and Adhering to New Protocols for Enhanced Worker Protection

Understanding the Need for Updated Safety Standards

In recent years, advancements in automotive technology have led to the widespread adoption of high-strength steel in vehicle construction. This shift has significantly impacted the landscape of auto body shop operations, particularly in frame repair and vehicle collision repair processes. As cars become increasingly safer and more robust, ensuring the integrity of structural components during repairs becomes paramount. Thus, updating frame repair safety standards is crucial to meet these evolving demands.

The need for revised guidelines arises from the complex nature of modern vehicle design and the diverse range of high-strength steel alloys in use. Unlike traditional metal, these advanced steels often require specialized techniques and equipment to ensure effective repairs without compromising structural integrity. Auto bodywork professionals must stay abreast of these changes to handle various types of vehicle collisions and maintain the safety standards expected in today’s market.

Key Changes and Improvements in High-Strength Steel Frame Repair

The recent updates to frame repair safety standards for high-strength steel frames mark a significant evolution in the automotive industry’s commitment to both safety and efficiency. Among the key changes, the introduction of advanced welding techniques has dramatically improved structural integrity during repairs, ensuring that cars with high-strength steel frames can be restored without compromising their initial strength and protection. This advancement is particularly crucial for modern vehicles equipped with sophisticated safety systems, where any disruption in frame integrity could impact overall vehicle performance and safety ratings.

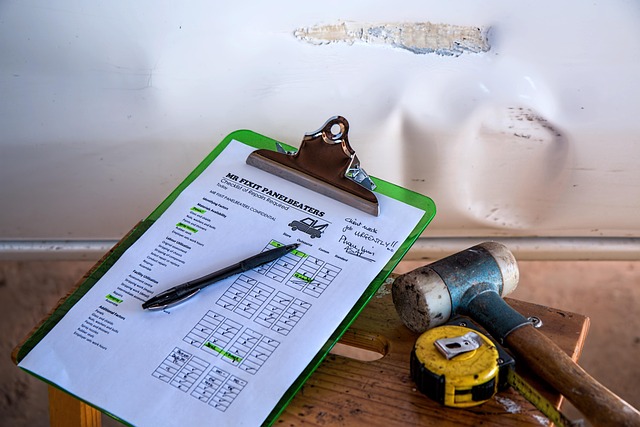

Moreover, the updated standards have streamlined auto body services by providing clear guidelines on using specialized tools and equipment designed for high-strength steel. This not only enhances the precision of car damage repair but also reduces the risk of auto detailing issues that may arise during the repair process. The new norms emphasize the importance of adhering to strict protocols to maintain the original structural design, ensuring that vehicles restored under these standards offer the same level of protection and performance as brand-new models.

Implementing and Adhering to New Protocols for Enhanced Worker Protection

The recent updates to frame repair safety standards highlight a significant shift in prioritizing worker protection during high-strength steel frame repairs. These new protocols are designed to mitigate risks associated with handling potent materials and complex procedures. By implementing these guidelines, auto frame repair shops can create a safer environment for their employees while ensuring the highest quality of work.

Adhering to the updated standards involves training staff on enhanced safety measures, such as proper personal protective equipment (PPE) usage, improved ventilation systems, and meticulous waste management protocols. This commitment not only aligns with best practices in the industry but also facilitates more efficient frame straightening and paintless dent repair techniques. The result is a modernized auto frame repair process that balances efficiency with worker safety.

The updates to frame repair safety standards for high-strength steel reflect a critical step forward in protecting workers and ensuring structural integrity. By implementing these new protocols, the industry can leverage the superior strength of high-strength steel while minimizing risks associated with its repair. Adherence to these standards is crucial for maintaining safe workplaces and promoting the responsible use of advanced materials in construction.