Tesla major structural repairs require specialized knowledge and equipment due to the unique engineering and lightweight materials used in their vehicles. Computerized Frame Pulling Systems, employing advanced algorithms and sensors, revolutionize this process by offering unprecedented precision, efficiency, and cost savings. The implementation of these systems involves several steps, including vehicle preparation, software scanning, creating digital blueprints, and precise pulling and realignment, ultimately ensuring high-quality finishes that meet Tesla's standards for restoration.

Tesla vehicles, known for their advanced technology, require meticulous care during major structural repairs. This article delves into the intricacies of Tesla’s structural repair process, focusing on the transformative impact of Computerized Frame Pulling Systems. We explore why these systems are essential, highlighting their precision and efficiency advantages over traditional methods. Through a step-by-step guide, we demonstrate how these innovations benefit both repair shops and Tesla owners, ensuring optimal vehicle restoration.

- Understanding Tesla Major Structural Repairs: The Importance and Challenges

- Computerized Frame Pulling Systems: Revolutionizing Repair Precision and Efficiency

- Step-by-Step Guide to Implementing and Benefits of Using These Systems for Tesla Vehicles

Understanding Tesla Major Structural Repairs: The Importance and Challenges

Tesla major structural repairs are a specialized and critical aspect of automotive maintenance, particularly for electric vehicle (EV) owners. These repairs involve addressing significant damage to a Tesla’s frame or chassis, which is the backbone of the vehicle’s structure. Given the advanced engineering and lightweight materials used in Tesla vehicles, such repairs demand precision and expertise to ensure the safety and integrity of the car.

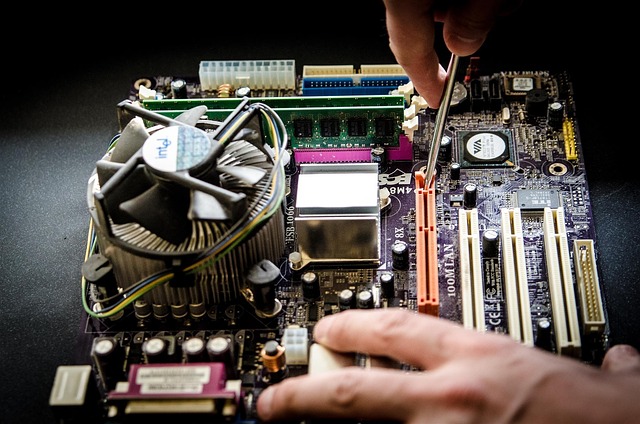

The challenges in Tesla major structural repair stem from several factors. First, the unique design and construction methods of these vehicles require specialized tools and knowledge that go beyond conventional auto body services. For instance, computer-aided frame pulling systems are often employed to accurately and safely straighten the frame without causing further damage or compromising structural integrity—a far cry from traditional car scratch repair techniques. Moreover, maintaining a seamless fit and finish during restoration is paramount, as any misalignment can affect the vehicle’s performance and aesthetics. This level of precision work necessitates a high-skilled workforce and advanced equipment, making it a complex yet essential service for Tesla owners seeking top-tier auto body restoration.

Computerized Frame Pulling Systems: Revolutionizing Repair Precision and Efficiency

Computerized Frame Pulling Systems have emerged as a game-changer in Tesla major structural repairs, offering unparalleled precision and efficiency. These advanced technologies utilize sophisticated algorithms and sensors to accurately measure and adjust the force applied during the repair process, ensuring minimal damage to surrounding components. By automating the frame pulling procedure, these systems significantly reduce the time typically required for manual labor, thereby streamlining the overall repair process.

This innovative approach not only enhances the accuracy of repairs but also contributes to cost savings and improved vehicle longevity. Unlike traditional methods, which might lead to misalignments or residual damage, computerized Frame Pulling Systems meticulously realign the vehicle’s structure, addressing issues like frame bent, crush, or distortion. This meticulous attention to detail is especially beneficial for complex Tesla models, where precision repair techniques are paramount to maintaining their advanced engineering and sleek design aesthetics.

Step-by-Step Guide to Implementing and Benefits of Using These Systems for Tesla Vehicles

Implementing computerized frame pulling systems for Tesla major structural repairs involves several key steps. Firstly, vehicle preparation includes ensuring proper safety measures and accessibility for the repair team. Next, advanced software is used to scan and map the vehicle’s frame, identifying any damage or misalignments accurately. Once the digital blueprint is created, specialized machinery precisely pulls and realigns the affected components, restoring structural integrity without compromising on Tesla’s high-quality standards.

The benefits of these systems are significant for both body shop services and vehicle restoration. They offer enhanced accuracy, reducing the risk of further damage during repairs. Computerized systems also streamline the process, saving time and labor costs compared to manual methods. Moreover, they enable precise adjustments, resulting in a more consistent and high-quality finish, meeting Tesla’s stringent requirements for car paint repair and overall vehicle restoration.

Tesla major structural repairs, once considered complex and time-consuming, are now revolutionized by computerized frame pulling systems. These advanced technologies offer unprecedented precision and efficiency, ensuring faster turnaround times and superior results. By implementing this innovative approach, Tesla service centers can enhance their capabilities, reduce costs, and ultimately provide customers with a superior repair experience. Embracing these changes positions businesses as leaders in the industry, ready to meet the evolving needs of Tesla vehicle owners.