Regular maintenance, including cleaning and inspection, can prevent Tesla Charge Connector failures. When issues arise, skilled technicians use advanced diagnostic tools to identify problems, such as damaged connectors, faulty wiring, or insulator wear. Auto body shops equipped for EV repairs leverage tools like multimeters and specialized equipment for accurate assessments and fixes. Best practices for long-lasting connectivity include insulation resistance tests, regular inspections, high-quality replacement parts, appropriate tools and techniques, and meticulous bumper repair.

In the ever-growing ecosystem of electric vehicles, Tesla charge connectors are essential for seamless charging. However, these components can fail due to various factors, leading to frustrating connectivity issues. This article delves into the world of Tesla charge connector repairs, offering a comprehensive guide on understanding failures, mastering insulation resistance tests, and implementing best practices to ensure long-lasting performance. Learn how to effectively troubleshoot and maintain your Tesla’s charging infrastructure.

- Understanding Tesla Charge Connector Failures

- Tools and Techniques for Repair and Insulation Resistance Testing

- Best Practices for Ensuring Long-Lasting Connectivity

Understanding Tesla Charge Connector Failures

Tesla Charge Connector failures can be frustrating for vehicle owners, especially considering the importance of seamless electric vehicle (EV) charging. Regular use, exposure to varying weather conditions, and potential physical damage are primary contributors to these issues. Corrosion and insulation degradation over time significantly impact performance, leading to connectivity problems or even total failure.

Proper maintenance, including regular cleaning and inspection, can prevent many such failures. However, when issues arise, Tesla Charge Connector Repair is crucial. Skilled technicians employ advanced diagnostic tools to identify problems, whether they’re related to damaged connectors, faulty wiring, or insulator wear. This process not only ensures reliable charging but also preserves the overall integrity of the EV’s electrical system, akin to maintaining top-notch auto body work for a vehicle’s exterior and interior.

Tools and Techniques for Repair and Insulation Resistance Testing

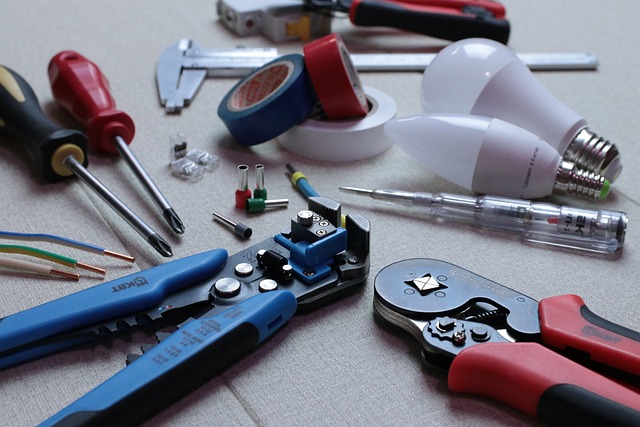

When it comes to Tesla charge connector repair, the right tools and techniques are paramount for ensuring effective and lasting solutions. Auto body shops and automotive collision repair centers specializing in electric vehicle (EV) repairs typically invest in advanced diagnostic equipment, such as multimeters and specialized EV testing tools, designed to accurately assess and address issues with charging systems. These tools allow technicians to pinpoint faulty connectors, monitor voltage levels, and measure insulation resistance, crucial steps in the repair process.

For Tesla charge connector repair, insulation resistance testing is a critical component. This involves using ohmmeter or specialized test equipment to check the electrical insulation between various components within the connector. By simulating current flow, technicians can identify any weak spots or areas of damage that may lead to arcing or short circuits. Such meticulous testing ensures not only the safety of EV owners but also enhances the reliability and longevity of these vehicles, mirroring the rigorous standards applied in Mercedes-Benz repair processes.

Best Practices for Ensuring Long-Lasting Connectivity

To ensure long-lasting connectivity with your Tesla charge connector repair, best practices involve several key steps. First, proper insulation resistance tests are crucial to prevent damage from electrical faults and moisture ingress. Regularly inspecting connectors for signs of wear, cracking, or corrosion is essential, as these can lead to poor contact and eventual failure.

During the repair process, it’s important to use high-quality replacement parts that meet Tesla’s specifications. Additionally, ensuring the car body shop has the right tools and techniques for precise repairs, such as expert Mercedes Benz repair skills, will maintain the structural integrity of your vehicle. This includes meticulous bumper repair when necessary, guaranteeing both safety and optimal charging performance.

Tesla charge connector repairs are essential for maintaining reliable electric vehicle charging. By understanding common failure causes, utilizing appropriate tools and techniques like insulation resistance testing, and adhering to best practices, owners can ensure long-lasting connectivity. Regular maintenance and prompt attention to issues will keep your Tesla’s charging system running smoothly, providing convenient and efficient access to sustainable energy.