The Mercedes 48V system, a cutting-edge automotive technology combining a 12V and 48V network, offers enhanced performance, efficiency, and safety features. Key components include a battery pack, power electronics, and sensors. Repairs demand specialized knowledge due to complex wiring harnesses, intricate sensors, and advanced modules, leading to higher costs. Collision repair shops require expertise in diagnosing and repairing this system for accurate repairs, especially for sophisticated dent work on Mercedes vehicles. Understanding the 48V system's intricacies is crucial for efficient Mercedes 48V system repair.

The Mercedes 48V system, a revolutionary power architecture, offers enhanced efficiency and performance in modern vehicles. This article delves into the intricate details of this advanced electrical system’s cost implications for repairs and diagnostics. We explore the key components, their functions, and initial investment comparisons with traditional setups.

Further sections discuss unique diagnostic challenges and the necessary tools, highlighting potential labor expenses. Additionally, we present a balanced view on maintenance costs and long-term savings, supported by real-world case studies, to provide a comprehensive understanding of the Mercedes 48V system’s financial considerations.

- Understanding the Mercedes 48V System: Components and Costs

- – Overview of the 48V system in Mercedes vehicles

- – Key components and their function

Understanding the Mercedes 48V System: Components and Costs

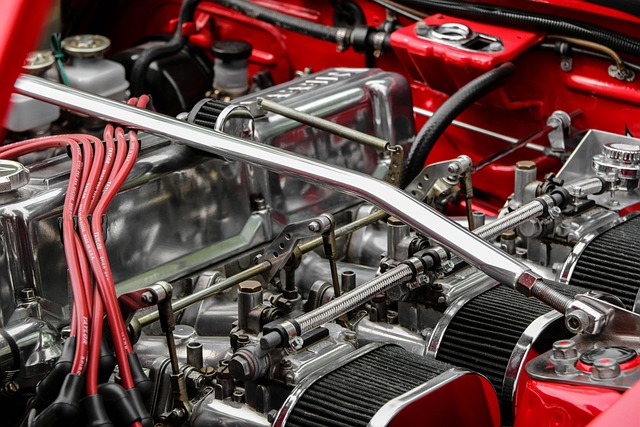

The Mercedes 48V system is a cutting-edge electrical architecture designed to enhance vehicle efficiency and performance. Comprising various interconnected subsystems, it’s a complex network that includes the main 48V battery, power electronics, and high-voltage components. Understanding this intricate setup is crucial for effective Mercedes 48V system repair, which involves specialized knowledge and tools.

When it comes to costs, several factors contribute to the expense of repairing or restoring this advanced system. The initial investment can be substantial due to the high-tech nature of its components, such as sophisticated sensors, advanced power modules, and state-of-the-art wiring harnesses. Moreover, specialized training is often required for technicians to keep up with the rapid advancements in 48V technology. Auto body services or automotive body shops specializing in these repairs may charge premium rates to cover the costs of staying at the forefront of this evolving field.

– Overview of the 48V system in Mercedes vehicles

The Mercedes 48V system represents a significant advancement in automotive technology, offering enhanced efficiency and performance across various models. This innovative system incorporates a dual-voltage architecture, combining a traditional 12V electrical system with a supplementary 48V network. The primary advantages lie in improved power distribution, allowing for faster engine startups, smoother operation of electric components, and enhanced overall vehicle dynamics.

Integrated into the system are various advanced systems such as electric motors, regenerative braking, and high-voltage batteries. This integration not only contributes to fuel efficiency but also facilitates modern safety features like active stability control and advanced driver-assistance systems (ADAS). For collision repair shops and auto frame repairs specialists, understanding this intricate network is crucial when dealing with Mercedes vehicles, ensuring accurate diagnostics and effective repairs for even the most sophisticated car dent repairs.

– Key components and their function

The Mercedes 48V system is a sophisticated network designed to enhance vehicle performance and efficiency, integrating electric and conventional powertrains seamlessly. Its core components include the 48-volt battery pack, a high-voltage rectifier, inverters, and various sensors. The battery pack stores energy, providing a robust power source for the electric components while also supporting the conventional engine during start-up and low-speed operations. The rectifier converts alternating current (AC) from the battery into direct current (DC), ensuring efficient power distribution throughout the system. Inverters, on the other hand, transform DC back to AC for use in electric motors or auxiliary devices. This intricate interplay of components enables advanced features such as regenerative braking and start/stop systems, contributing significantly to fuel efficiency and reduced emissions in modern Mercedes vehicles.

Beyond these key elements, the 48V system incorporates various sensors that monitor critical parameters like voltage, current, temperature, and pressure. These sensors play a vital role in maintaining optimal system performance and safety by providing real-time data for control units, which then adjust power distribution and component operation accordingly. This sophisticated monitoring system ensures not only efficient energy utilization but also reliable vehicle performance, making Mercedes 48V system repair a specialized task that requires expertise in both electrical systems and vehicle integration. As with any complex automotive network, troubleshooting and repairing issues in the 48V system often involves intricate diagnostics, highlighting the importance of professional auto glass repair, vehicle body repair, and restoration techniques to restore these advanced systems to their peak operating conditions.

The Mercedes 48V system, a pioneering technology in automotive diagnostics, involves a intricate network of components that contribute to enhanced performance and efficiency. Understanding the cost factors associated with its repair is essential for owners and mechanics alike. By recognizing the key components and their roles, we can better navigate the complexities of this system, ensuring optimal maintenance and minimizing repair expenses for this advanced Mercedes technology. This knowledge empowers individuals to make informed decisions regarding 48V system repair, ultimately enhancing the overall reliability and longevity of these cutting-edge vehicles.