Traditional auto body repair methods struggle with intricate shapes and thin metal panels, potentially causing future structural issues. High-strength steel repair, leveraging laser welding and specialized coatings, offers precise, minimally invasive repairs that preserve both structural integrity and aesthetic value, marking a significant improvement over conventional techniques. This advanced approach ensures vehicles are restored to their original safety standards, addressing the limitations of traditional methods in today's automotive industry.

In the world of structural repairs, High-Strength Steel Repair (HSSR) is a game-changer, addressing the limitations of traditional methods that often leave structures vulnerable to recurring damage and safety hazards. Conventional techniques struggle with durability, especially in demanding environments, leading to costly maintenance and structural weaknesses. HSSR offers a robust solution by providing superior strength and longevity through specialized steel alloys and advanced repair processes. This article explores why HSSR is transforming repairs, delving into its advantages, implementation steps, and real-world success stories that demonstrate its potential to revolutionize infrastructure maintenance.

- The Limitations of Traditional Repair Methods

- – Discuss the vulnerabilities and drawbacks of conventional repair techniques in dealing with structural damage.

- – Highlight the need for stronger and more durable solutions.

The Limitations of Traditional Repair Methods

Traditional repair methods for damaged vehicle bodies often rely on welding and painting as primary solutions. While effective, these techniques have limitations, especially when dealing with complex geometric shapes or thin metal panels. Welding can introduce stress points that may lead to future structural issues, and the painting process requires meticulous preparation to achieve a flawless finish. Moreover, traditional methods may not be suitable for repairing delicate components or preserving the original aesthetic of classic vehicles.

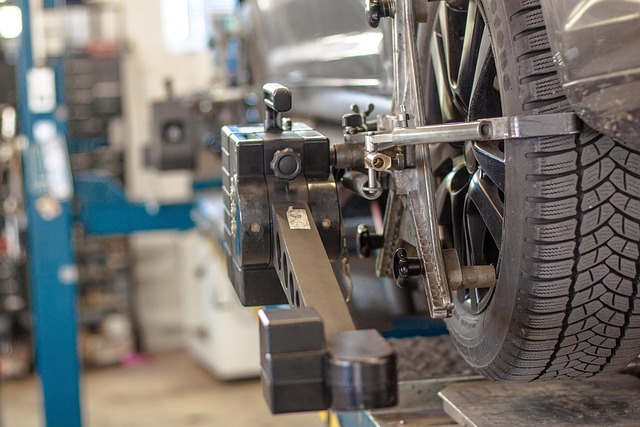

High-strength steel repair offers a revolutionary approach by utilizing advanced techniques like laser welding and specialized coatings. These modern methods provide greater precision, ensuring minimal distortion during repairs. Compared to auto dent repair using older strategies, high-strength steel repair can preserve the structural integrity and visual appeal of a vehicle body shop’s creations. This innovative process has transformed the capabilities of body shops, enabling them to handle complex repairs with enhanced efficiency and superior results.

– Discuss the vulnerabilities and drawbacks of conventional repair techniques in dealing with structural damage.

Conventional repair techniques for structural damage often fall short due to their limitations in handling complex geometry and high-stress areas. Traditional methods may involve welding or bolting, which can be labor-intensive and time-consuming, especially in the case of car body restoration and auto body restoration. Moreover, these techniques might not provide the required strength and durability, leaving structures vulnerable to future failures.

When it comes to car bodywork services, high-strength steel repair emerges as a game-changer. It offers enhanced structural integrity and improved performance by utilizing advanced materials and specialized techniques. This method overcomes the drawbacks of conventional practices, ensuring that vehicles or structures are restored to their original strength and safety standards.

– Highlight the need for stronger and more durable solutions.

In today’s world, where safety and reliability are paramount, especially in the automotive industry, there is an increasing demand for robust and durable repair solutions. Traditional methods often fall short when it comes to handling extensive damage or restoring structural integrity. This gap has led to a growing recognition of high-strength steel repair as a game-changer in the field. The need for stronger materials is evident, particularly in car body restoration projects, where every component must withstand rigorous testing and real-world conditions.

High-strength steel offers unparalleled strength and resistance, ensuring that vehicles not only look their best after auto painting and detailing but also perform optimally. Unlike conventional materials, this advanced steel can handle extreme forces without compromising structural integrity, making it ideal for complex auto body restoration tasks. With its superior properties, high-strength steel repair is revolutionizing the way we approach vehicle repairs, promising safer, more durable outcomes.

High-strength steel repair is a revolutionary approach that addresses the inherent limitations of traditional methods, offering a game-changer solution for structural repairs. By utilizing advanced materials and techniques, this innovative process ensures durability, strength, and longevity in even the most challenging scenarios. Embracing high-strength steel repair not only enhances safety but also reduces long-term maintenance costs, making it a smart choice for both professionals and property owners alike.