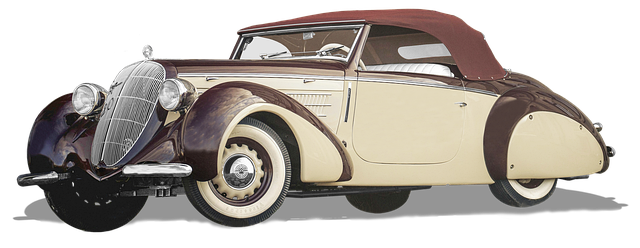

Specialty collision hardware is a set of advanced tools and equipment tailored for precise auto body repairs and car paint services. These precision-engineered jigs, fixtures, guns, and applicators significantly enhance efficiency, accuracy, and repair quality, allowing technicians to streamline workflows and deliver superior outcomes. By investing in this specialized equipment, clients receive top-tier bodywork and painting services, ensuring quicker turnaround times without compromising on quality. This hardware is particularly crucial for dent removal, bumper repair, and achieving seamless aesthetic results that match original vehicle specifications, fostering long-term customer relationships.

In the realm of automotive repairs, technicians strive for precision and efficiency. This is where specialty collision hardware steps in as a game-changer. Unlike standard parts, these specialized tools cater to the unique challenges of collision repair, offering distinct advantages. From enhancing work accuracy to streamlining processes, this article explores why technicians prefer specialty collision hardware, ultimately leading to improved repair quality and heightened customer satisfaction.

- Understanding Specialty Collision Hardware: Defining the Difference

- Advantages for Technicians: Increased Efficiency and Better Results

- The Impact on Repair Quality and Customer Satisfaction

Understanding Specialty Collision Hardware: Defining the Difference

Specialty collision hardware refers to specialized tools and equipment designed for specific tasks in auto body repairs and car paint services. These aren’t your standard tools found in a typical workshop. They’re tailored to address unique challenges presented by modern vehicle designs, advanced materials, and precise finishes. From precision-engineered jigs and fixtures that facilitate intricate alignment during auto frame repair to specialized guns and applicators for complex coating and painting processes, these hardware options offer advantages over standard alternatives.

Understanding the difference lies in the level of detail and customization they enable. Specialty collision hardware often incorporates innovative designs that cater to the intricacies of car bodywork services. They enhance efficiency, accuracy, and ultimately, the quality of repairs. By investing in such specialized equipment, technicians can streamline their workflows, reduce cycle times, and deliver superior outcomes for clients seeking top-tier auto body repair and meticulous car paint services.

Advantages for Technicians: Increased Efficiency and Better Results

Technicians working on car bodywork services and auto painting tasks often find themselves gravitating towards specialty collision hardware for a few very good reasons. Firstly, these specialized tools and equipment offer distinct advantages in terms of efficiency and precision. When it comes to intricate vehicle bodywork repairs or precise painting jobs, standard hardware simply cannot compete with the level of control and finesse that specialty products provide.

Specialty collision hardware allows technicians to work faster while achieving superior results. Customized designs cater to specific challenges posed by modern car bodies, ensuring that every detail is accounted for. This translates into quicker turnaround times without sacrificing quality, which is particularly beneficial in high-demand workshops offering comprehensive car bodywork services.

The Impact on Repair Quality and Customer Satisfaction

When it comes to repairing vehicles, especially after a collision, the choice of hardware plays a pivotal role in the outcome. Technicians skilled in auto body work recognize that using specialty collision hardware can significantly enhance repair quality and customer satisfaction. Unlike standard hardware, these specialized parts are designed with specific collision-related challenges in mind, ensuring more precise and durable repairs.

For instance, when dealing with dent removal or bumper repair, specialty hardware offers better alignment and retention, resulting in a seamless finish that matches the vehicle’s original specifications. This attention to detail not only increases the aesthetic appeal of the repaired vehicle but also ensures its structural integrity. Satisfied customers are more likely to return for future auto body work, fostering long-term relationships between repair shops and their clientele.

Specialty collision hardware offers technicians a distinct advantage in terms of efficiency and repair quality. By investing in specialized tools, mechanics can streamline their processes, ensuring better outcomes for vehicle repairs. This, in turn, enhances customer satisfaction by reducing repair times and potentially preventing future damage. The preference for specialty hardware underscores the importance of staying ahead in an industry where precision and expertise are paramount.