In collision repair, adhering to OEM standards is paramount for safety, quality, and aesthetic precision. Best practices involve specialized training in advanced techniques, CAD systems, robotically assisted welding, and using genuine OEM parts for compatibility and durability. Implementing these guidelines—including damage assessment, precise measurements, high-quality finishing, efficient technology use, and transparent communication—ensures top-tier workmanship, customer satisfaction, and consistent, exceptional results meeting industry standards.

In the realm of automotive restoration, adhering to Original Equipment Manufacturer (OEM) standards is paramount. This article explores the essential collision repair best practices that meet OEM requirements, ensuring top-tier quality and customer satisfaction. We’ll delve into understanding stringent OEM standards, implementing effective workshop procedures, and upholding rigorous quality control measures post-repair. By embracing these practices, collision centers can deliver exceptional results while maintaining meticulous craftsmanship.

- Understanding OEM Standards for Collision Repair

- Implementing Effective Best Practices in the Workshop

- Ensuring Quality Control and Customer Satisfaction Post-Repair

Understanding OEM Standards for Collision Repair

In the collision repair industry, meeting Original Equipment Manufacturer (OEM) standards is paramount to ensuring vehicle safety and quality. OEM requirements set a high bar for collision centers, encompassing every aspect from structural integrity to aesthetic precision. These standards are designed to maintain the original performance and appearance of vehicles, guaranteeing driver and passenger safety as well as long-term reliability.

Collision repair best practices revolve around adhering to these stringent OEM guidelines. This involves specialized training for technicians in advanced repair techniques, such as precision measuring, computer-aided design (CAD) systems, and robotically assisted welding. Furthermore, the use of genuine OEM parts is crucial, ensuring compatibility, durability, and precise fitment across all components, including auto glass repair, bumper repair, and other intricate panel work.

Implementing Effective Best Practices in the Workshop

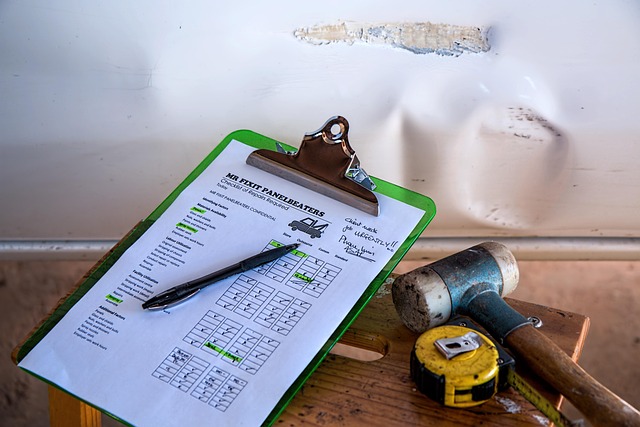

In the dynamic realm of collision repair, best practices are not mere suggestions but imperative guidelines that ensure top-tier workmanship and customer satisfaction. By implementing these practices within the workshop environment, auto body shops can elevate their standards to meet or exceed Original Equipment Manufacturer (OEM) requirements. This involves a meticulous approach to every stage of the repair process, from accurate damage assessment to precise measurements and high-quality finishing. Well-trained technicians play a pivotal role in this, as they are equipped with the knowledge and skills to handle various collision scenarios effectively.

The integration of advanced technologies is another crucial aspect. Modern tools and equipment designed for collision repair streamline tasks such as auto glass repair, ensuring precision and efficiency. Furthermore, utilizing specialized car paint services that adhere to OEM specifications guarantees a seamless blend of color and finish, restoring the vehicle’s pre-collision aesthetic. Through consistent adherence to these best practices, collision repair shops can foster an environment of excellence, delivering exceptional results that meet and exceed industry standards.

Ensuring Quality Control and Customer Satisfaction Post-Repair

After a collision repair, meticulous quality control measures are paramount to ensure customer satisfaction and maintain the vehicle’s original equipment manufacturer (OEM) standards. This involves thorough inspections, where every part of the repair is assessed for precision, alignment, and structural integrity. Advanced tools and technology can aid in this process, providing accurate measurements and ensuring repairs meet OEM specifications.

A satisfied customer is a reflection of successful collision repair best practices. Auto body repair experts must address any concerns, offering transparent updates throughout the process. This includes demonstrating the effectiveness of car scratch repair techniques and explaining how they enhance the overall restoration, thus fostering trust and confidence in the repair work performed.

In conclusion, implementing collision repair best practices that align with Original Equipment Manufacturer (OEM) requirements is paramount for achieving superior quality control and enhancing customer satisfaction. By understanding OEM standards, adopting effective workshop procedures, and prioritizing post-repair inspections, collision centers can ensure their work meets the highest industry benchmarks. Embracing these best practices not only guarantees the safety and reliability of repaired vehicles but also fosters trust and loyalty among customers who demand excellence in auto body repairs.