The sunroof repair industry is evolving rapidly thanks to technological advancements that offer more efficient, accurate, and aesthetically pleasing solutions. Tools like 3D scanning, laser measurement systems, CAD software, virtual reality training, digital design, and advanced manufacturing ensure precise fits and enhanced structural integrity. These innovations streamline repairs, reduce human error, and minimize leakages, surpassing conventional methods. AI and machine learning algorithms promise further optimization, predictive maintenance, and improved customer service in the future, revolutionizing sunroof repair replacement processes.

In the automotive industry, sunroof repair and replacement have traditionally presented challenges due to intricate designs and precision requirements. However, technological advancements are revolutionizing this domain, offering new solutions for enhanced accuracy and efficiency. This article explores how modern technology is transforming sunroof repairs, from 3D imaging and laser-guided tools to AI-assisted diagnostics. By delving into these innovations, we uncover the benefits, state-of-the-art tools, and future prospects that promise to elevate sunroof repair precision to new heights.

- The Current State of Sunroof Repair: Challenges and Room for Improvement

- How Technology is Transforming Sunroof Replacement Precision

- Benefits, Tools, and Future Prospects of Technologically Enhanced Sunroof Repairs

The Current State of Sunroof Repair: Challenges and Room for Improvement

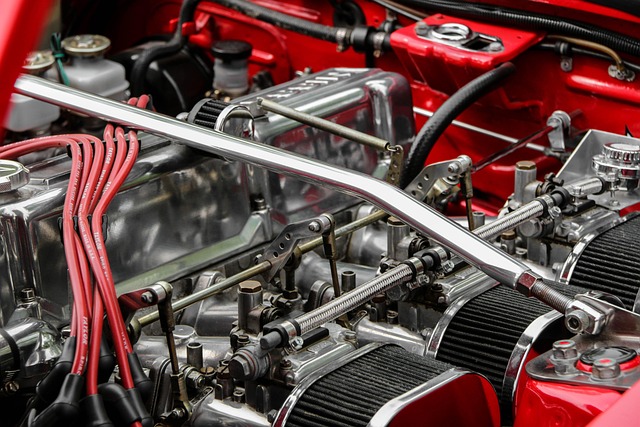

The current state of sunroof repair presents a unique set of challenges for automotive technicians and enthusiasts. Traditional methods often involve labor-intensive processes, requiring precise measurements and skilled hands to replace damaged or malfunctioning sunroofs. The complexity lies in the intricate design and structural integration of these features within a vehicle’s roof system. With advancements in technology, there is now a growing demand for more efficient and accurate sunroof repair replacement solutions.

Automotive repair services are evolving to meet this need, integrating innovative tools and techniques into their practices. Frame straightening equipment, for instance, can aid in correcting any misalignments, ensuring the new sunroof component fits seamlessly. Auto body restoration processes can also be enhanced with digital imaging and 3D scanning technologies, allowing technicians to accurately assess damage and plan replacements, thereby improving overall precision and customer satisfaction.

How Technology is Transforming Sunroof Replacement Precision

Technology is revolutionizing sunroof repair replacement precision, bringing about significant advancements that benefit both auto mechanics and vehicle owners. Modern tools like laser measurement systems and 3D scanning technology enable precise measurements, ensuring that new sunroofs fit perfectly with the vehicle’s body lines and existing components. This level of accuracy prevents unsightly gaps or misalignments commonly seen in traditional repair methods.

Additionally, digital design software and advanced manufacturing techniques facilitate the creation of customized parts tailored to specific car models. This not only enhances the overall aesthetic appeal but also improves structural integrity. Moreover, virtual reality (VR) simulations are increasingly used for training auto technicians, immersing them in realistic sunroof replacement scenarios. Such innovations streamline the process, reduce human error, and ultimately provide a higher quality of repair compared to conventional car collision repair or car paint repair methods.

Benefits, Tools, and Future Prospects of Technologically Enhanced Sunroof Repairs

The integration of technology into sunroof repair and replacement processes has revolutionized the automotive industry, offering numerous benefits to both technicians and vehicle owners. By leveraging advanced tools and digital solutions, precision in sunroof repairs has reached new heights. Technologies such as computer-aided design (CAD) software enable technicians to create accurate measurements and designs, ensuring seamless integration of new sunroofs with existing vehicle bodywork. This level of precision minimizes the risk of leaks and structural weaknesses, enhancing overall vehicle safety and performance.

Moreover, modern digital tools facilitate faster repair times and improved efficiency. High-tech sensors and laser scanners can quickly identify damage and pinpoint exact replacement parts needed, streamlining the procurement process. Automated welding robots and advanced adhesive systems further contribute to precise assembly, resulting in superior bond strength and durability. Looking ahead, the future of sunroof repairs is poised for even greater innovation. Artificial intelligence (AI) and machine learning algorithms have the potential to optimize repair procedures, predict part failures, and enhance customer service through predictive maintenance, taking tire services and auto frame repair to new levels of efficiency and reliability.

The integration of technology into sunroof repair replacement processes has revolutionized precision, offering significant advantages. By leveraging advanced tools and techniques, professionals can now execute repairs with enhanced accuracy and efficiency. This shift not only improves the quality of work but also reduces the time and cost associated with sunroof maintenance. As technology continues to evolve, we can expect even more innovative solutions in the future, further streamlining sunroof repair replacement procedures and ensuring optimal performance and safety for all vehicles.